How to Use a Step Drill Bit

A step drill bit is a versatile tool that can be used for various applications. In this blog post, we will discuss the different ways on how to use a step drill bit and provide tips on how to get the most out of this tool. We will also offer a few recommendations for specific applications.

If you’re looking for a versatile and efficient drilling option, a step drill bit may be the perfect tool for you. Step drill bits can be used to create accurate and clean holes in various materials, making them a popular choice among DIYers and professionals alike. This post will discuss what step drill bits are, how to use them, and some of their key benefits. Read on to know more!

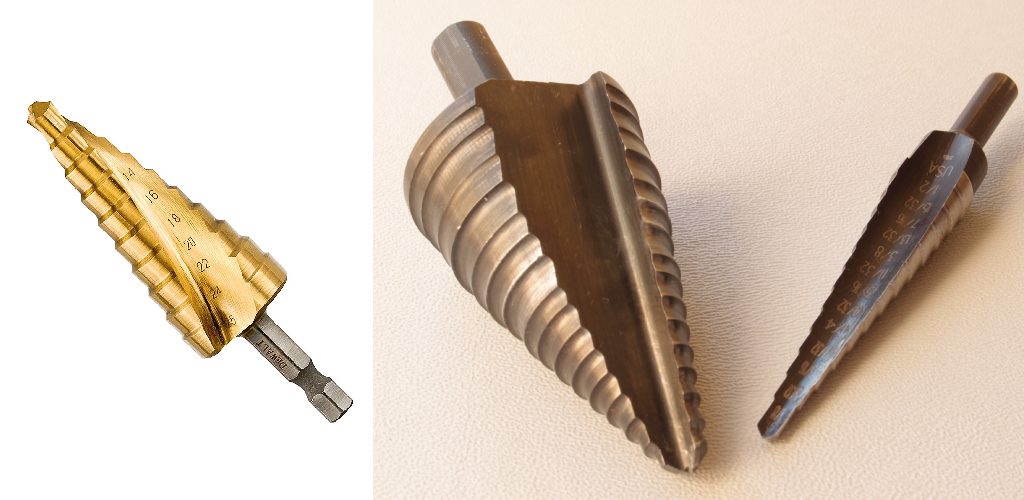

What is a Step Drill Bit?

A step drill bit, or stepped drill bit, is a type of drill bit that has multiple cutting surfaces. The different diameters are achieved by grinding down the shank of the drill bit to other sized parts. This means you get more than one drill bit design in just one tool!

One downside to this is that you can’t control the size of the finished drill bit very accurately because, after step drilling, there is still an unground portion of the shank that has not been ground down. They are often used in regular twist drills to drill through metal or wood that would be much harder when using a larger drill bit. Many people also use them in place of spade drills to save time and money.

What Are Step Drill Bits Used for?

Step drill bits are used to drill through thin metal, plastic, or wood pieces. A step drill bit can also be a step bit or step down drill bit. This drill bit is used for precision drilling and creates an even hole that allows the user to fit multiple objects into one pre-drilled hole, such as a dowel pin.

Step bit drills are designed with a low flute count, which means that there are fewer steps on the cutting edge of the drill bit. These drill bits are usually used in a hand-powered tool; however, some step drill bits are designed to be used in an electric or pneumatic powered machine.

Why Should You Use Step Drill Bit?

A step drill bit is a kind of drill bit that has a larger diameter shank and a smaller diameter cutting end. This design aims to provide the user with two different diameters that allow for multiple uses, no matter what material they have available.

In addition, it will enable the user to perform tasks such as drilling pilot holes or boring larger holes. This latter function can also be accomplished by using a spade bit. However, many find that the step drill bit is more accurate than its counterpart.

The main disadvantage of using the step drill bit is that it takes up more space than other bits due to its dual-diameter design. Many users also claim that the larger shank can sometimes pose a problem when trying to access confined areas, such as in the case of drilling through the material. For this reason, it is recommended that you use one of the step bits with an adjustable chuck.

10 Easy Ways on How to Use a Step Drill Bit

1. Determine Bolt Size

A step drill bit has multiple steps allowing for different sized holes. It is used to find the bolt size that fits inside the hole. The hole is slowly drilled into the material until it feels resistant. If no drilling continues when the drill interferes with the bolt, then step down another size until you can drill through without any pressure.

2. Drill Holes in Metal

Using a drill press can make things easier by having accuracy and making all the steps the same size. A step drill bit is also used to drill holes in sheet metal without cutting through it. This allows for a less invasive hole that can be cut out later if needed.

3. Drilling Into Concrete

A step drill bit is used with a hammer drill to create holes into concrete materials. First, the drill is fed into the substantial material. The drill must be supported on both sides of the surface to create an even hole. A pilot hole should be drilled first using a small bit and then a step drill bit of the appropriate size.

4. Select a Step Drill Bit

The hole size to be drilled will determine what sized step drill bit is needed. Use a ruler to measure the inside diameter hole to find out how big it is. A standard chart made just for this purpose makes it more accessible.

5. Clamp the Material

Ensure the material you are working with is secured in place, or it will move and could be dangerous. For safety reasons, it would be best to clamp the material down.

6. Mark the Depth

Mark the drill bit with tape on each side of where you want to make a hole. This will let you know when you are finished drilling. The depth can be set on a drill press so the bit will stop when it reaches the required depth.

7. Mark the Center of the Hole

A center punch can be used to mark where to drill, but make sure other marks weren’t added by mistake. The center should also be marked on the opposite side of where you are drilling because this is one of the most important steps.

8. Threading Holes

Use a step drill bit with a tap wrench to make holes for screws. This is done by using the correct type of tap (usually called a “tapping” set) and matching it with the appropriate size of step drill. The hole will be drilled larger than needed so the tapered edges on the screw can fit but are not too large.

9. Marking Screw Locations

If you need to mark the location of screws or other metal objects before drilling, use a magnetized punch to keep it from slipping as you strike it. Punch markings into the drill bit instead of directly marking the material; otherwise, they may slip and damage your work surface.

10. Make Masks for Painting

You can use a step drill bit to make masks for painting. Use masking tape or another type of tape, cut out strips and wrap them around the material. This is done so only the area you want to be painted has painted, not all around it.

Some Tips and Suggestions

1. Try not to “push” the bit down on top of the workpiece. The weight of your drill press should allow you to let go of the bit and have it guide itself into the material. If you have trouble with this, slow down or use a lighter machine.

2. Drill bits cut when they penetrate the material, not when they are being pushed from the side. For a cleaner cut, try drilling at a slower rate of speed.

3. If you do not have a step drill bit and want to use a standard twist drill bit, you can achieve similar results by clamping your workpiece into place and using the drill bit like an end mill. In this case, you will not be using the step drill bit’s ability to plunge into a surface. You will use it as a milling tool instead.

4. Do not position your hands close to where the cut is being made by the step drill bit or attempt to hold your workpiece down with them; they will get caught in the spinning bit.

5. Always wear safety glasses when drilling metals to avoid any metal shards or other debris from damaging your eyes.

6. Always wear gloves when working with power tools or any equipment that can cause serious injury.

7. To prevent your hands from slipping, try using a clamp to secure the workpiece in place rather than holding it down yourself. This also helps to ensure you drill into the exact center of your workpiece.

Precautions and Safety Measures

1. Always wear eye protection while working.

2. Keep the drill bit sharp and clean, which helps you to work faster and avoid accidents.

3. Keep your hands away from the moving drill bit while operating it.

4. Do not touch any part of the power tool while plugged in.

5. Disconnect the power tool from the power source before you change, clean, or store it.

6. Check for cracks and damage of all parts regularly while working with a drill bit to keep yourself safe from accidents caused by sharp pieces breaking off, which can be propelled at high speeds and cause severe injury to your eyes, hands, and face.

7. Be sure to wear a respirator for additional safety if the drill bit is a pneumatic one or if it produces fumes or dust while working.

Conclusion

A step drill bit is a drill with various bits attached to one unit. They are very versatile and can be used for many different applications, including drilling holes in metal or wood. Step drills have been around since the 1800s, but they became popular with home DIY enthusiasts when modern versions were developed using improved materials such as cobalt steel alloys.

If you’re looking to purchase your first set, be sure to check out this blog post on how to use a step drill bit, so you don’t mess up your project! If you need any help or want to know more, then feel free to comment below!