How to Build a Rope Bridge Across a Canyon

To build a rope bridge across a canyon, you will need some supplies and some friends willing to help. The supplies you’ll need include sturdy ropes, sturdy trees on either side of the canyon, and sturdy rocks to fasten the ropes to.

Building the bridge is simple but requires teamwork and precise measurements. This article will teach you how to build a rope bridge across a canyon that can span any distance. Follow these simple steps, and you’ll be able to cross any canyon with ease.

12 Effective Ways on How to Build a Rope Bridge Across a Canyon:

1. Preparing to Clean Your Cylinder Heads

First, you have to take the truck out of gear. Turn on your flashers and then shift into the park if it has an automatic transmission. If it has a manual transmission, just take the shifter out of gear. Use the parking brake to keep your truck from running away while you’re working under it.

2. Gather the Necessary Equipment

You’ll need some tools for this one. A 10mm or 11mm wrench, a large screwdriver, wire cutters and zip ties should do the trick. You’ll also need a length of rope long enough to span the distance from one side of the canyon to the other. Something at least 1/4 inch thick should do the job.

3. Find the Vacuum Leaks

You will need to find the vacuum leaks in your engine so you can replace the vacuum hoses if needed. Start by cranking up the engine and warming it up for a few minutes. Then shut it off and remove the air cleaner. Make sure your engine is completely cool before you try to remove any vacuum lines from their connectors on the intake manifold.

4. Ensure the Head Is Completely Disassembled

With your crescent wrench, carefully remove the cylinder head bolts one at a time, or else you’ll damage the threads. After removing all of them, grab hold of both sides of the cylinder head and pull backward to separate it from the engine block. Then, carefully set it on a clean work surface with the intake manifold facing up.

5. Take the Cylinder Head to Your Local Auto-Parts Store

Carry your cylinder head into your local auto parts store, along with the rest of the items you need to buy for this job. The service desk can help you find a replacement intake manifold gasket and any other hardware or equipment you may need.

They should be able to sell you some new bolts, nuts, and washers since you’ll be re-using these. Unfortunately, there are some items you can’t buy in the store that may require a trip to another supplier or even the dealer parts department.

6. Disassemble the Intake Manifold

You need to remove the old intake manifold gaskets before you can put new ones in their place. To do this, start by removing the intake manifold brace. Use your large screwdriver to pry it out of its spot, then use your wrench to remove the bolts that hold it in place. Once you have all of the old gaskets removed, you can put new ones in their place. You can use a paper gasket, but a rubber one provides better sealing.

7. Use a Plastic Scraper to Remove Head Gasket Material

Remove all of the old sealants from around the intake manifold gasket. This is best done with a plastic scraper, but you can also use your screwdriver or wrench if it’s made of metal. It would help if you also scraped away any glues or washers used during assembly. Finally, make sure there are no bits of debris on the surfaces where the new gasket will be placed.

8. Place the Cylinder Head in the Tub

Place your container under the cylinder head so that it’s ready to catch any excess oil. Then, use a pair of pliers to take off the dipstick and lower the cylinder head into the tub. Please make sure you place plastic over the bottom first, so there is no chance of accidently scratching it up.

9. Remove Excess Oil from the Cylinder Head

To change the oil in your car, first remove the drain plug from the bottom of the cylinder head with a screwdriver or wrench. Put an oil pan underneath to catch the old oil. Once all the oil has drained, pull the dipstick back out and replace it with a new one. Pour 4 ounces of fresh engine oil through the spark plug holes. Add 4 ounces of new oil to each cylinder, then remove the excess with your plastic scraper.

10. Submerge the Cylinder Head in the water

Carefully lower the cylinder head into your container of water. Make sure that you don’t splash any of the oil on yourself! If you do get some on yourself, it’s best to wash it off with soap and water as soon as possible. Once the gasket is covered in soapy water, use your finger or scraper to check for corners that may not be sealed properly.

11. Replace Gasket Material and Washers

Use your screwdriver or wrench to replace any washers that may have worn down while you were removing the gaskets, then place a new intake manifold gasket in its spot on the cylinder head. Next, carefully lower the intake manifold over the cylinders, then use your pliers to put the manifold brace back in its spot.

12. Re-Install the Cylinder Head Bolts

Use your crescent wrench to re-install all of the cylinder head bolts one by one. Make sure that you tighten them down evenly so that there are no gaps between the intake manifold and the cylinder head. You may need to add more oil or soapy water while you do this. Also, use a gasket sealant along the edges of the intake manifold for added protection against leaks.

Some Tips and Suggestions

1. Don’t spend too much time or money on the rope until you first know that it’s going to work. Then, make sure that your bridge is strong enough. The strength of materials used in bridges will be covered later in this article.

2. Instead of having one big piece of rope for the whole bridge, make several chains or loops of rope from the same amount of rope. For example, instead of having one piece that is 100 feet long, have four loops 25 feet each. This will result in a stronger bridge with less weight to carry on your back.

3. Try testing different knots and ropes before you go out into the canyon. These can determine how useful they are if you have to fix them.

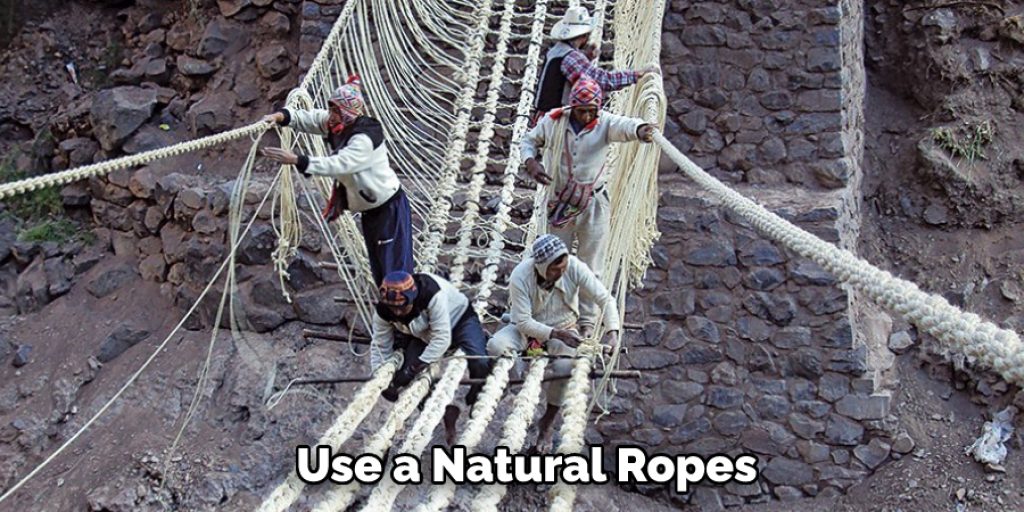

4. If possible, try using natural ropes/loops already in the area instead of carrying all your ropes in.

5. Bring an extra piece of rope or many small pieces so if one breaks or comes undone, you can easily replace it without having to go back for another rope.

6. Try to decking from a light yet strong material such as plastic or cloth netting. You can also add some padding onto the decking for added comfort and safety, though do not go overboard with this idea because you will only have more weight on your back that you have to carry all the way.

Conclusion

When you’re faced with an obstacle, it’s important to know how to get past it. The construction of a rope bridge is no easy task and requires careful planning to succeed. With this guide on building your rope bridges, you’ll have the tools necessary for overcoming any obstacle that may cross your path.

We hope you enjoyed this article and learned a lot about how to build a rope bridge across a canyon. If you want more information on these projects, please get in touch with us at our website or by phone.