How to Use Drill as Grinder

Drills are a versatile tool that can be used for several purposes. A drill grinder can be a great option if you’re looking for a way to effectively grind down welds and other sharp edges on your metal projects. In this post, we will discuss how to use drill as grinder. We’ll also provide some tips on choosing the right one for your needs.

First, we will cover using a drill as a grinder, including choosing the right bit and speed. Then, we will go over some tips for getting the most out of your drill-grinder. Finally, we will give you some examples of projects that you can use your drill-grinder on. Read on to learn more!

8 Benefits of Using Drill as Grinder

1. Increased Drilling Speed:

When you use a drill as a grinder, you can achieve high speeds quickly. This is because the drill’s motor is already running at high speeds.

2. Increased Cutting Ability:

The grinding action of the drill bit on the material being ground helps increase the drill bit’s cutting ability. As the drill bit grinds away at the material, it creates small pieces that are easier to cut than the larger piece that was there before. This increased cutting ability can be helpful when drilling through tougher materials.

3. Grinding Action:

The grinding action of a drill is very important to its effectiveness as a grinder. When using a drill as a grinder, you will want to apply pressure to the ground object while the drill is rotating. This pressure will cause the drill’s bit to grind against the object, removing material. You should use a light to moderate pressure when grinding with a drill, as too much pressure can damage the drill bit or the object being ground.

4. Easier to Control:

The grinder is much easier to control than a drill when grinding away small amounts of material. It is easy to go too fast and grind away more than you want with a drill. With a grinder, it is much easier to control the speed and amount of material being removed.

5. More Precise:

A drill can be used to remove large chunks of material at a time, which can be helpful when grinding down large pieces. However, it can also remove smaller amounts of material more precisely, which is great for finishing touches.

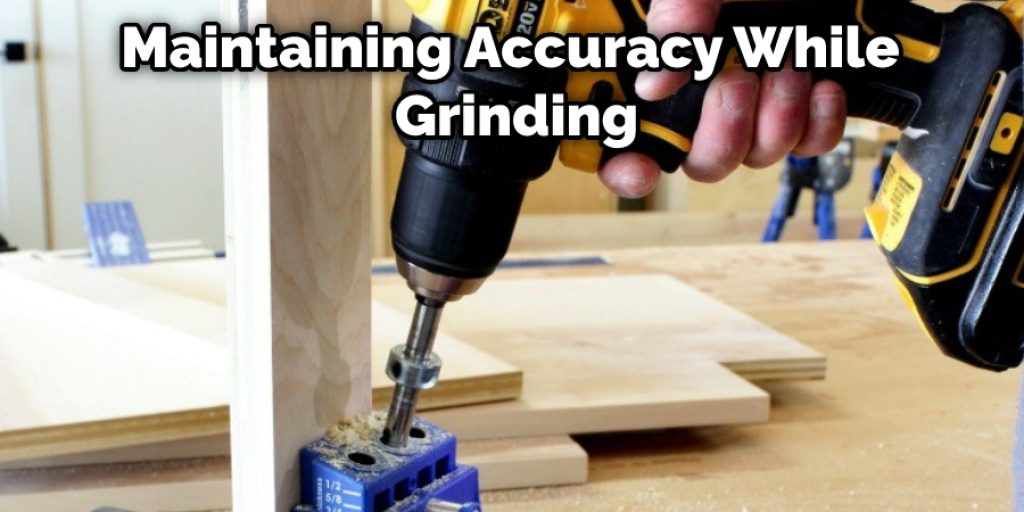

6. Accurate Grinding:

Drills can be effectively used as grinders if their accuracy is maintained. The use of a jig can assist in maintaining accuracy while grinding. A jig is simply a guide that helps keep the drill bit on track while it is ground. The jig can be as simple as a piece of wood with a hole drilled in it or as complex as a CNC-machined jig.

7. Extended Drill Life:

The use of a grinder wheel can prolong the life of your drill bit by removing any built-up material that may have formed on the bit’s cutting surface. Grinding with a diamond wheel will also sharpen the drill bit, further increasing its life.

8. Reduced Drill Breakage:

One of the biggest benefits of using a drill grinder is reducing drill breakage. When drills are properly sharpened, their edges are sharper and the point is more acute. This means that less force is required to penetrate the material, reducing the likelihood of the drill breaking.

Step by Step Instructions: How to Use Drill as Grinder

Step 1: Locate the Drill Bit.

The drill bit is located at the front of the drill. The part of the drill spins when the drill is turned on. The bit can be changed out depending on the hole you need to drill.

Step 2: Insert the Drill Bit into the Chuck.

The chuck is the part of the drill that holds the drill bit in place. The chuck is located at the back of the drill. To insert the drill bit into the chuck, hold the drill bit with your dominant hand and insert it.

Step 3: Tighten the Chuck.

Tighten the chuck by turning it clockwise with the chuck key. Be careful not to overtighten the chuck, as this can damage the drill bit or the chuck itself. Once the chuck is tight, you’re ready to start grinding! Place the drill bit in the chuck and tighten it down. Be sure to use a vise grip or some other clamp to hold the drill bit in place.

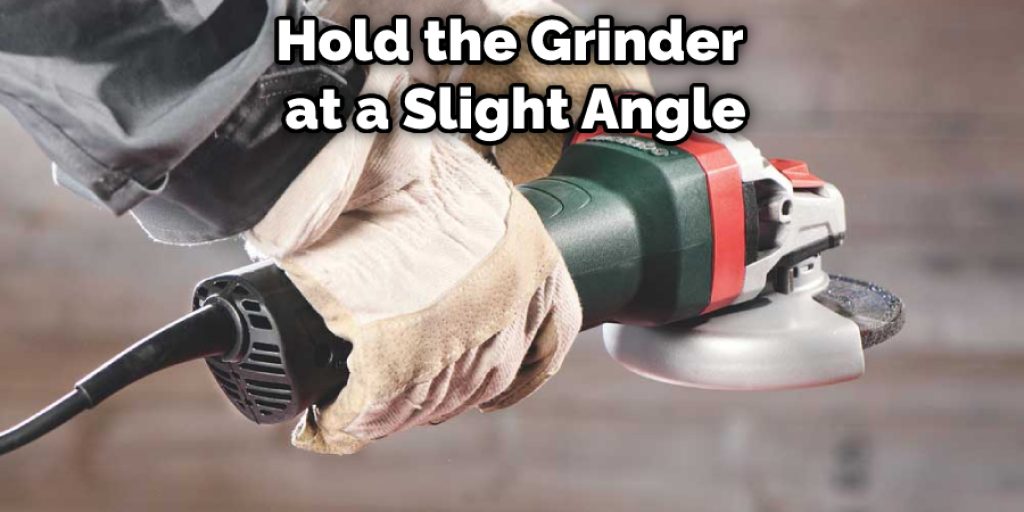

Step 4: Start Grinding.

With the drill bit secured in the chuck, you’re ready to grind. First, hold the grinder at a slight angle and run it along the length of the drill bit. Be sure to keep the grinder moving at all times or end up with a very uneven surface.

Step 5: Finish Grinding.

Once you’ve ground down the length of the drill bit, it’s time to finish up. Hold the grinder at a 90-degree angle and run it along the edge of the drill bit. Be sure to keep the grinder moving at all times, or you’ll end up with a very uneven surface.

Step 6: Remove the Drill Bit from the Chuck.

To remove the drill bit from the chuck, hold the drill bit with your dominant hand and loosen the chuck by turning it counterclockwise with the chuck key. Be careful not to lose the chuck key! Once the chuck is loose, pull the drill bit out of the chuck.

Step 7: Clean the Drill Bit.

Once you’re done grinding, it’s important to clean the drill bit. Use a brush or a rag to remove all of the grinding residues from the bit. This will help keep the bit sharp and prevent it from rusting.

Congratulations! You’ve just learned how to use a drill as a grinder. Now you can easily sharpen your drill bits at home without paying for a professional sharpening service.

Some Helpful Tips and Suggestions

1. When grinding with a drill, use the correct bit size. A too-large bit can cause the drill to bog down and overheat.

2. If possible, use a corded drill instead of a battery-operated one. Corded drills have more power and are less likely to bog down.

3. Always wear safety goggles when grinding with a drill. Bits and fragments can fly off the workpiece and cause injury.

4. Keep the drill bit sharp by occasionally honing it on a whetstone. A dull bit will not only bog down the drill, but it can also be dangerous.

5. Use plenty of cutting fluid when grinding with a drill. This will help keep the bit cool and minimize wear on the drill bit.

6. If possible, use a vise or other holding device to secure the workpiece. This will help keep your hands safe while you’re grinding.

7. Ensure the work area is well-ventilated when grinding with a drill. The fumes from the cutting fluid can be dangerous if inhaled.

8. Always unplug the drill when not in use. This will help prevent accidental starting and minimize the risk of electrical shock.

You Can Check It Out to: Remove Battery From Cordless Drill

Final Thoughts

In conclusion, using a drill as a grinder can save you time and money. It is an efficient way to remove material quickly and accurately. With the right attachments and bits, a drill can also be used to grind many different materials. Be sure to take your time when choosing the right bit and attachment to achieve the best results for your project.

Although drilling as a grinder is not a new technique, it is still essential to learn how to do it properly to get the most out of your tools. By following the steps outlined in this article, you will know how to use drill as grinder to remove material and achieve the desired finish on your workpiece. Have you tried using the drill as a grinder before? What tips do you have for our readers? Let us know in the comments below!