How to Dress a Diamond Wheel

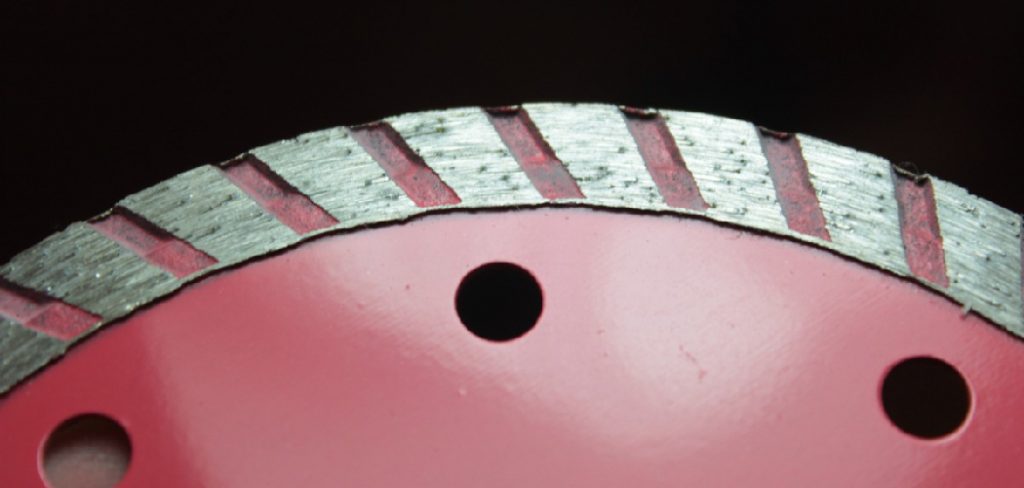

As a professional diamond wheel dresser, it is important to know how to dress a diamond wheel correctly. This will ensure that your tools work at their best potential and achieve the desired results. Diamond grinding wheels are used for precision grinding and polishing of hard materials. A wheel dresser is a tool used to keep the diamond wheel sharp and free from built-up or broken-off abrasive material.

Proper dressing of the diamond wheel is essential for maintaining its optimum performance. In this blog post, we will discuss how to identify the surface condition of a diamond wheel and how to dress it accordingly. We will also provide tips for getting the most out of your diamond wheel dresser. So read on for more information.

Step by Step Process: How to Dress a Diamond Wheel

Step 1: Mounting the Wheel

Secure the diamond wheel in a vice or chuck. Ensure that it is mounted correctly and securely before starting the dressing process.

Step 2: Inspecting the Wheel

Inspect the wheel to identify its surface condition. If there are any cracks, chips, or missing segments, it is best to replace the wheel before proceeding. If the wheel’s surface is uneven or there is build-up on the abrasive particles, then it will need to be dressed.

Step 3: Dressing the Wheel

There are several ways to dress a diamond wheel. The type of dressing depends on the condition of the wheel and the desired results. If the wheel is only mildly damaged or has light build-up, then truing it with a single-point diamond-impregnated tool is usually sufficient. However, using a multi-point diamond tool or even a grinding wheel dresser for more severe damage or build-up may be necessary.

Step 4: Truing The Wheel

Truing is the process of removing abrasive material from the wheel to restore its original shape. To true a wheel, hold the diamond tool perpendicular to the wheel surface and move it in a back-and-forth motion across the entire surface of the wheel.

Step 5: Cutting the Fluids

After the wheel has been dressed, it is important to cut the fluids to remove any debris or metal particles that may have been generated during the dressing process. This will help prevent clogging and ensure that the diamond wheel continues to perform at its best.

Simply add a few drops of cutting fluid to the diamond wheel and then spin it for a few seconds. The cutting fluid will remove any metal particles and debris from the wheel’s surface, leaving it clean and ready for use.

Step 6: Applying Coolant

Once the diamond wheel has been dressed and cut, it is important to apply coolant to the wheel’s surface. This will help to keep the diamond abrasive particles from overheating and becoming dull.

To apply coolant, add a few drops of water or oil-based coolant to the diamond wheel and then spin it for a few seconds. The coolant will help keep the diamond particles cool and sharp, allowing them to cut more effectively.

Step 7: Checking the Wheel

After the coolant has been applied, it is important to check the diamond wheel for any damage. If there are any cracks, chips or missing segments, it is best to replace the wheel before continuing. If the wheel’s surface is still uneven or there is build-up on the abrasive particles, then it will need to be dressed again.

Step 8: Cleaning the Excessive Particles

Once the diamond wheel has been dressed and cut, it is important to clean off any excessive particles. This will help to prevent clogging and ensure that the diamond wheel continues to perform at its best. The easiest way to clean the diamond wheel is with a brush and some water.

Start by wetting the brush and then gently scrubbing the surface of the diamond wheel. Be sure to go in a circular motion to don’t miss any spots. Once you’ve gone over the entire surface, rinse the diamond wheel off with water to remove any debris or metal particles.

Step 9: Applying Lubricant

After the diamond wheel has been cleaned, it is important to apply lubricant to the wheel’s surface. This will help to keep the diamond abrasive particles from overheating and becoming dull. To apply lubricant, simply add a few drops of water or oil-based lubricant to the diamond wheel and then spin it for a few seconds. The lubricant will help to keep the diamond particles cool and sharp, allowing them to cut more effectively.

Step 10: Storing the Wheel

Once the diamond wheel has been used, it is important to store it properly to prevent damage. The best way to store a diamond wheel is in a cool, dry place. If the diamond wheel is going to be stored for an extended period, it is best to wrap it in a soft cloth or place in a padded box. This will help to protect the diamond abrasive particles from damage.

When you’re ready to use the diamond wheel again, follow the steps above to dress and cut the fluids.

Few Tips for Truing and Conditioning Diamond Wheel

1. Always use a new or freshly sharpened wheel for truing.

2. Do not true the wheel while it is still wet from cutting fluid as this can damage the abrasive particles.

3. Be sure to apply coolant to the diamond wheel after truing to keep the diamond particles from overheating.

4. If the diamond wheel is going to be stored for an extended period, it is best to wrap it in a soft cloth or place it in a padded box. This will help to protect the diamond abrasive particles from damage.

5. Check the diamond wheel for damage before each use. If there are any cracks, chips, or missing segments, it is best to replace the wheel before continuing.

6. Always clean off the diamond wheel to prevent clogging and ensure optimum performance after each use.

7. Apply lubricant to the diamond wheel after cleaning to keep the diamond particles from overheating and becoming dull.

8. Be sure to check the runout of the diamond wheel regularly to ensure that it is in good condition.

Things to Keep in Mind When Dressing a Diamond Wheel

1. Wheel Speed:

The speed at which the wheel rotates will affect how well the diamond particles cut. A slow speed is typically used for harder materials, while a higher speed is better for softer materials.

2. Wheel Grit:

The size of the diamond particles will also affect the quality of the cut. Smaller particles are better for finer cuts, while larger particles are better for rougher cuts.

3. Applied Pressure:

Applying too much pressure to the diamond wheel can cause it to break or chip. Too little pressure will result in a poor cut. The best way to find the right pressure is to experiment until you find the sweet spot.

4. Work Speed:

The speed at which you move the material across the diamond wheel will also affect the quality of the cut. If you move too quickly, the cut may be shallow or rough. If you move too slowly, the cut may be deep but not very precise. So again, experimentation is key to finding the right balance.

5. Material Removal Rate:

The material removal rate is the amount of material you remove with each wheel passing over the workpiece. This is dictated by the type of wheel you’re using, the hardness of your workpiece, and how much pressure you’re applying to the wheel. To calculate the material removal rate, first determine the wheel’s width.

This is usually listed on the side of the wheel. For example, a typical diamond wheel might be 1/8″ wide. Then, measure the circumference of the wheel. To do this, wrap a piece of string or a tape measure around the widest part of the wheel and then measure the length of the string. Finally, divide the wheel’s width by the circumference to get the material removal rate.

Can a Diamond Grinding Wheel Be Dressed

Yes, a diamond grinding wheel can be dressed. Dressing a diamond grinding wheel is important because it helps to keep the diamond abrasive particles from becoming clogged or damaged. To dress a diamond grinding wheel, simply add water or oil-based coolant to the wheel and then spin it for a few seconds.

The coolant will help keep the wheel from overheating and help clean any debris that may be on the wheel. It is important to note that you should never use a metal object to dress a diamond grinding wheel as this can damage the wheel. Always use a coolant when dressing a diamond grinding wheel and make sure that the wheel is spinning safely before adding any coolant.

Conclusion

It is important to dress a diamond wheel correctly to keep it sharp and to run smoothly. The proper way to do this will depend on the type of wheel and the materials used in its construction. We hope this blog post has helped guide you on how to dress a diamond wheel.

By following these simple steps, you can ensure that your diamond wheel stays in good condition and lasts for a long time. Have you ever dressed in a diamond wheel before? If not, be sure to give it a try! You may be surprised at how easy it is once you know-how.