How To Fix A 2 Cycle Engine That Ran Straight Gas

This post is for people who have a 2 cycle engine that ran straight gas. We are going to help you on how to fix a 2 cycle engine that ran straight gas and get your bike running again! Many people make this mistake, but don’t worry – we’ve got some easy steps for you to follow to avoid it in the future. Let’s go over how to diagnose the issue, what might be wrong with your bike, and lastly, how to fix it!

What Causes The Issue:

1) The fuel mixture is too rich. This causes the engine to stall or die repeatedly but not turn over on its own.

2) Gasoline that has been mixed with a poor quality oil (like kerosene). This can also cause your bike to run poorly and eventually stop.

3) Water in the fuel. This can cause your engine to seize up and not start, even if it is mixed with a quality oil

4) A dirty air filter or exhaust system. These are often clogged by dirt from riding off-road and will keep the bike running poorly until they’re cleaned out.

5) Fuel line is clogged. If the fuel mixture becomes too lean, this can cause the engine to overheat and eventually stop running.

How to Diagnose the Issue

- If your engine ran straight gasoline, the problem could be caused by many different issues. Therefore, it is important to diagnose the issue before attempting a fix. The easiest way to do this is to look at your spark plugs and see what type of gas you were running when operating properly (i.e., ethanol or non-ethanol ).

- If the plugs were wet with gasoline when you changed them, this indicates that your engine ran straight gas. In addition to running on ethanol or non-ethanol mix, it’s also possible for a two-cycle engine to run straight gas if something was plugged into the air intake (i.e., lawnmower blades).

- If you are dealing with a lawnmower that has been run on straight gasoline, the issue could be as simple as removing any obstruction in the air intake. However, if this doesn’t work and your spark plugs remain wet after running for an extended period of time, there may be a leaky fuel line or tank sealant that may have been improperly applied.

Things You’ll Need:

- A spark plug wrench

- An air filter that fits your engine size

- Fuel line or hose clamps that fit your fuel filter diameter.

- New gas canister with fresh gasoline

- A new fuel filter.

- Clean towel or shop rag

Instructions: How to Fix a 2 Cycle Engine That Ran Straight Gas

Step One:

First, you will need to drain the fuel tank.

Step Two:

Find your gas cap and remove it from the engine by turning counter-clockwise with a wrench or screwdriver.

Step Three:

Now that your gas cap is removed, you can unscrew the carburetor base from both sides of the bike’s body using an Allen wrench. This will give you access to the carburetor so that you can clean it or make any necessary adjustments.

Step Four:

Carefully remove any excess fuel from the carburetor and drain it into a container for disposal or recycling.

Step Five:

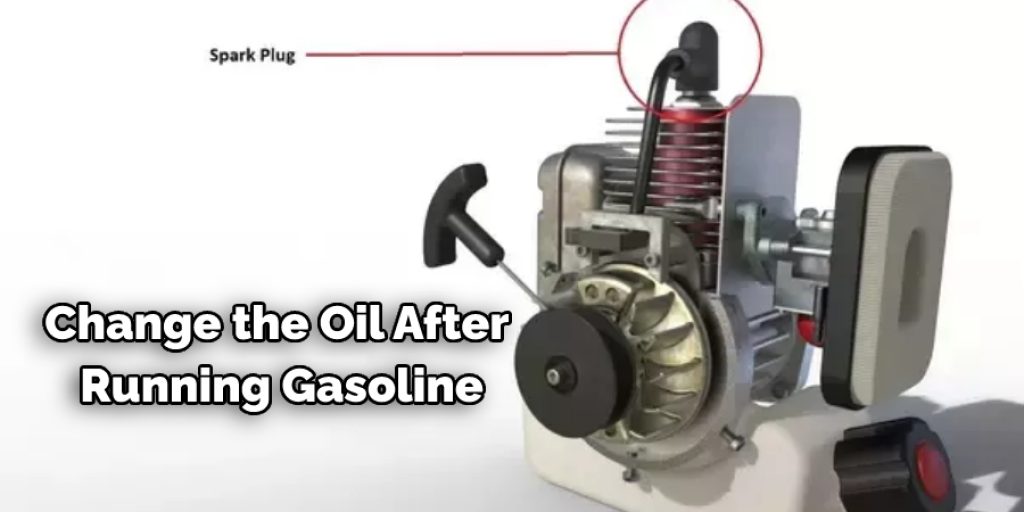

The next step is to locate your spark plug wire connection by following the wiring harness running over the top of the engine until you see where they connect with wires on both sides of the bike. Before disconnecting any wires, make sure to label each wire with a piece of tape or something similar and note where they connect.

Step Six:

Disconnect the wires from the spark plug by using an Allen wrench to loosen them. Remove the wire connection and disconnect any excess wiring that is in your way of removing it.

Step Seven:

Next, remove any metal fuel lines or clamps holding fuel line connections on both sides of the engine with a screwdriver or pliers.

Step Eight:

Remove the air filter and set it aside for now, then remove any clamps that are holding on to fuel lines or wires near the carburetor if they’re in your way of removing the engine from the bike frame.

2 Cycle Engine Repair and Maintenance Guide:

- If the engine ran straight gas, run two fuel tanks through it to clean out any residue. You can also change your oil and filter at this time as well.

- If you suspect that there are deposits in the carburetor or spark plugs from running gasoline, change those items too. Again, please make sure they’re from the same manufacturer.

- Clean off any dirt or corrosion from your muffler and spark arrestor too, both of which act as a filter for this engine type.

- Finally, you should change the oil after running gasoline through it to be safe. Ensure that you have an air/fuel mixture screw wrench on hand when changing the oil.

- You’ll want to run compressed air through your engine for a few minutes after everything is securely in place and tightened to be sure that any remaining gas particles are cleared away from the piston area of the engine.

Conclusion:

Have you tried to know how to fix a 2 cycle engine that ran straight gas but couldn’t find information on this topic? If so, then this blog post may be just what came for you!

Fixing your engine yourself is possible. But one of the most common mistakes people make when using gas-powered lawn equipment is gasoline instead of diesel. Unfortunately, this can lead to a buildup in the engine, which will eventually cause it to stop running altogether.

There are several ways you can tell if your 2 cycle engine has been run on gasoline, but one way is by looking for white smoke coming from the exhaust pipe. If this happens, immediately turn off and disconnect the power source (if applicable) before any further damage occurs.