How to Oil Ingersoll Rand Impact Wrench

An Ingersoll Rand impact wrench is a must-have tool for any mechanic or DIY enthusiast. This article will explain how to oil Ingersoll Rand Impact Wrench, which will help prevent corrosion and make the tool last longer.

This blog post contains information on what tools are required, where to find the oil fill area, and how often you should lubricate your impact wrench. It also explains why it’s essential to practice safety precautions when working with an impact wrench. You can also learn about some of our favorite wrenches that we’ve used and reviewed. Read on to know more.

10 Reasons Why You Should Oil Ingersoll Rand, Impact Wrench:

- Prevents failure of the tool’s components.

- It helps in the optimal performance of the tool, which is essential for proper application.

- It causes less wear on the tool’s components and prolongs the lifespan of tools.

- It avoids the risk of operator injuries because it facilitates a smooth operation.

- It prevents rust and corrosion of parts and components from ensuring the proper functionality of the tool.

- Enhances safety by preventing breakdowns and accidents while operating tools because it facilitates the correct application of the tool at all times.

- Reduces cost by helping optimum use of tools, allowing for longer tool lifespan and less replacement and maintenance costs.

- It helps to prevent damage to workpieces because it facilitates the precise and perfect application of the tool.

- Enhances work efficiency by preventing accidents that can cause delays in completing tasks; this is helpful for both individual workers and companies and manufacturers and retailers of tools.

- It gives the tool longer life, reducing costs for the replacement of tools.

Step by Step Guide: How to Oil Ingersoll Rand Impact Wrench

You probably shouldn’t be using it if you don’t know how to oil an Ingersoll Rand impact wrench. The oil keeps the moving parts of your air, or electric-powered tool working smoothly and prevents damage by keeping dirt out. There are several different air impact wrenches, so ensure you get the correct oil for your one. Otherwise, you risk harming your tool.

Step One: Purchase the Proper Oil

Several different types of Ingersoll Rand impact wrench require different oils. Therefore, it is essential to purchase the correct oil for the type of tool that you have. You can purchase the oil online or in any tool store.

Step Two: Drip Oil Into the Chuck

Once you have the proper oil, remove the plug from your Ingersoll Rand impact wrench. Take off any guards or attachments on the end of the tool if they are still attached. Make sure that there is no dirt in it before you open it up. Once everything is cleared out, drip some oil into the chuck where the socket attaches.

You can check it out to How to Oil Wahl Beard Trimmer

Step Three: Wipe Off the Oil

You will need a soft cloth and some paper towels for this step. Next, gently wipe off any excess or spilled oil. This is especially important if you’re using an electric tool because the excess oil may damage sensitive electrical components in your impact wrench. Once you have removed all of the extra oil, you are ready to use your Ingersoll Rand impact wrench again.

Step Four: Oil Your Air Impact Wrench

To oil an air impact wrench, remove the battery pack if necessary and remove the cap on the end of the impact wrench that looks like a small cone or hat. Next, lubricate the inside of this cone with your air impact wrench. You will need to turn it upside down.

Take off the cap on top of the tool to access the oil reservoir. Use a small piece of cloth or paper towel to soak up any extra oil inside of your impact wrench. To fill it back up, pour some oil into the tray where the old one was located previously. Make sure you use the exact oil recommended by your air impact wrench manufacturer.

Step Five: Use a Different Method for Electric Impact Wrenches

If you have an electric impact wrench, you should check your manual to learn how much oil it recommends you use. Most electric wrenches require a specific type of drip metal or low-viscosity oil safe for operating sensitive electronic tools. You can generally purchase this specialized oil at any hardware store, but make sure you purchase the correct type for your impact wrench.

Step Six: Reattach Your Cap

Once you have used the oil in your air or electric impact wrench, make sure to replace the cap securely. If you don’t, dust and dirt will get into your tool’s moving parts. This will quickly damage your impact wrench and could even make it unusable.

Step Seven: Store Your Impact Wrench Safely

After you have finished oiling your impact wrench, store it in a safe, dry place. If you are storing an electric model for more than three days, make sure to remove the battery pack and store that separately.

You Can Check It Out to Remove a Destroyed Oil Filter

Some Tips and Advice:

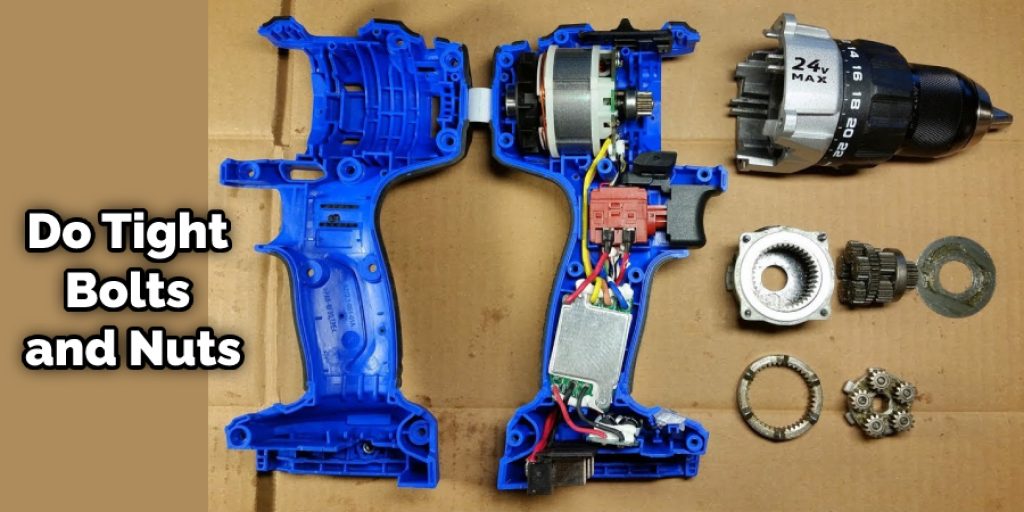

- Ingersoll Rand air impact wrench is a great tool to have when you have to do tight bolts and nuts.

- The air wrench has been an essential part of construction equipment for decades.

- These must be oiled regularly to increase their life and prevent any trouble in the future.

- It is also important to oil it regularly to ensure that they do their job properly.

- This air impact wrench can be used in various types of job sites like construction, repair, and assembly lines.

- These are also known as masonry drills because they are mostly used on hard surfaces like rocks and bricks.

- There are different kinds of masonry drills available with various features to choose from.

Conclusion:

An impact wrench is a tool that helps you loosen or tighten bolts and nuts with force. A good quality one will have six settings to choose from, including low torque for delicate jobs and high torque for hard ones. This guide has shown you how to oil the Ingersoll rand impact wrench so it can be used effectively.

To get started, unscrew the plug on the bottom of the device’s barrel-shaped case where the air outlet valve is located. Next, pour about two ounces of motor oil into this opening until it reaches just below the top edge of the hole, a little more if necessary but not less than an ounce because too much may leak out when closing up again.