How to Rewind Boat Lift Cable

Did you know that boat lift cables can be rewound? Rewinding your boat lift cable is a great way to save money and avoid the hassle of having to replace it. This blog post will show you how to rewind boat lift cable. We will also provide some tips on how to prevent damage to the cable. So stay safe, and enjoy boating!

What Causes Boat Lift Cable to Break?

Boat lift cables are exposed to the elements and can break down over time due to sun damage, saltwater corrosion, or wear and tear. In addition, the cable can become frayed if it is not wound correctly. Improperly wound cables can cause the cable to kink, leading to breakage. Another common cause of cable breakage is overloading the lift.

This can happen if you try to lift a boat that is too heavy or if you place too much weight on the cable. Additionally, if the cable is not lubricated, it can become dry and brittle, which can eventually cause it to snap. The other major cause of boat lift cable breakage is old age. With time, the cable will eventually degrade and break. Lastly, some people try to repair their cables, leading to further damage and breakage.

Why Should I Rewind My Boat Lift Cable?

Rewinding your boat lift cable is a great way to save money. However, replacing a boat lift cable can be expensive, so it is much cheaper to rewind the old one. In addition, it can be challenging to find a replacement cable that is the same size and type as the one you have. By rewinding your old cable, you can be sure that it will fit your lift correctly.

Another reason to rewind your boat lift cable is to avoid the hassle of having to replace it. If you have ever had to replace a boat lift cable, you know that it is not a fun task. In addition, it can be difficult to thread the new cable through all of the pulleys and guides. By rewinding your old cable, you can avoid this hassle.

Finally, rewinding your boat lift cable is a great way to prevent damage to the cable. If the cable is not wound correctly, it can become kinked, leading to breakage. Again, by rewinding the cable, you can avoid this problem.

Step by Step How to Rewind Boat Lift Cable

1. Disconnecting the Cable

The first step is to disconnect the cable from the boat lift. This is because you will need to remove the old cable before you can install the new one. To do this, first, remove the clamp that is holding the cable in place. Next, use a pair of pliers to loosen the set screw that is holding the cable in place.

Once the set screw is loosened, you should be able to pull the cable out of the lift. If the set screw is too tight, you may need to use a drill to remove it. Avoid using too much force, as you may damage the lift.

2. Measuring the Cable

Once the cable is disconnected from the lift, you will need to measure it. This is because you will need to know how much cable to buy when you rewind it. To measure the cable, find the end that is not attached to the lift. Next, measure the cable length from this end to the end that is still attached to the lift.

Make sure to include the length of any clamps or other attachments. If you are unsure how to measure the cable, you can always take it to a hardware store and have them do it for you. Try to be as accurate as possible, as you don’t want to buy too much or too little cable.

3. Cutting the Cable

Once you have measured the cable, you will need to cut it. To do this, first, find the end that is not attached to the lift. Next, use a pair of wire cutters to cut the cable at this point. Make sure to leave enough cable so that you can reattach it to the lift.

Try to make a clean cut so that the cable will be easy to rewind. If the cable is too short, you will not be able to reattach it to the lift. Avoid cutting too much cable, as you will waste it.

4. Stripping the Cable

Once you have cut the cable, you will need to strip it. This is because you need to remove the old outer casing before rewinding it. To strip the cable, find the end that is not attached to the lift first. Next, use a pair of wire strippers to remove the outer casing from this end of the cable.

Make sure only to remove the outer casing and not the inner wires. If you damage the inner wires, the cable will not work properly. Avoid stripping too much of the cable, as you will need some of the outer casing to reattach it to the lift.

5. Attaching the Clamp

After you have cut and stripped the cable, you will need to reattach the clamp. First, find the end of the cable that is not attached to the lift. Next, use a pair of pliers to reattach the clamp. Make sure that the clamp is tight so that it will not come loose. If the clamp is too loose, the cable may come out of the lift while you are using it. Avoid overtightening the clamp, as you may damage the cable.

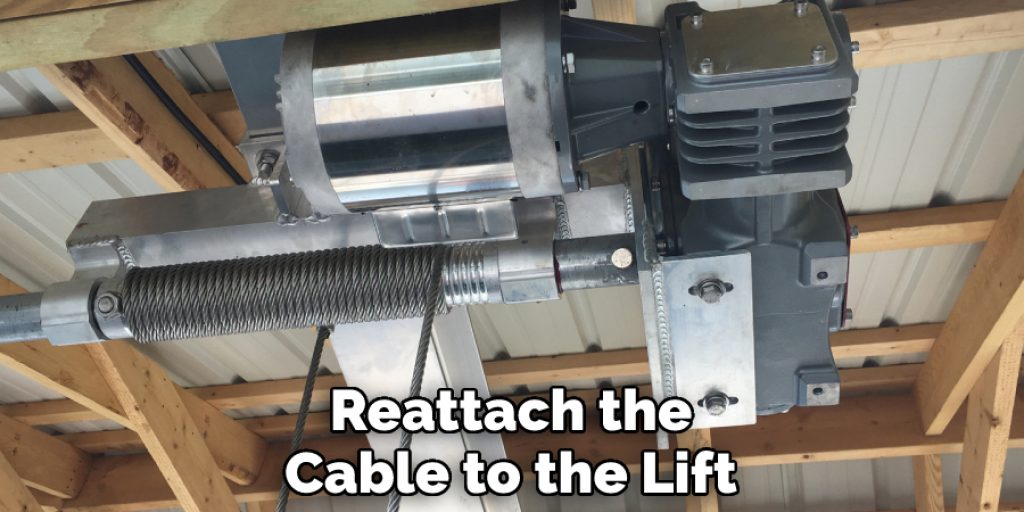

6. Attaching the Cable to the lift

Once the clamp is in place, you will need to reattach the cable to the lift. To do this, first, find the end of the cable that is still attached to the lift. Next, use a pair of pliers to loosen the set screw. Once the set screw is loosened, you should be able to pull the cable out of the lift.

If the set screw is too tight, you may need to use a drill to remove it. Avoid using too much force, as you may damage the lift. Once the cable is out of the lift, you can reattach it by following the same steps in reverse. Make sure to tighten the set screw so that the cable will not come out of the lift while you are using it.

7. Rewinding the Cable

Once the cable is reattached to the lift, you will need to rewind it. To do this, first, make sure that the lift is in the down position. Then, attach the winch handle to the winch, and start winding the handle clockwise. Continue winding the handle until the cable is fully wound.

Make sure to wind the cable evenly so that it will not become tangled. Once the cable is fully wound, you can use the lift as normal. Avoid winding the cable too tightly, as this may damage it.

8. Lubricate the Cable

Once you have wound the cable, you will need to lubricate it. This is because the cable can become dry and brittle over time. Find the end that is not attached to the lift to lubricate the cable.

Next, use a spray lubricant to coat the entire length of the cable. Make sure to lubricate the inside of the outer casing as well. This will help to protect the cable from rust and corrosion. Avoid using too much lubricant, as this can attract dirt and debris.

9. Adjust the Tension

After lubricating the cable, you will need to adjust the tension. This is because the cable can become too loose over time. To adjust the tension, first, find the adjusting screws. There are usually two of them, one on each side of the lift.

Next, use a wrench to turn the screws clockwise. This will help to tighten the cable. Avoid turning the screws too much, as this may damage the lift. Once the tension is adjusted, you can use the lift as normal.

10. Test the Boat Lift

After completing all the above steps, you will need to test the boat lift. To do this, first, make sure that the lift is in the down position. Then, attach the winch handle to the winch, and start winding the handle clockwise.

Continue winding the handle until the lift is in the up position. Make sure to keep winding until the lift is fully raised. If the lift does not raise all the way, you will need to adjust the tension. Once the lift is up, you can use it as normal.

Conclusion

So, that is how to rewind boat lift cable. Following the above steps, you can easily and efficiently rewind your boat lift cable. Remember always to lubricate the cable after you have wound it. This will help to protect the cable from rust and corrosion. Also, make sure to adjust the tension regularly. This will help to keep the lift functioning properly. Thanks for reading!