How to Tighten a Bolt That Keeps Spinning

Have you ever had a bolt that won’t tighten and keeps spinning? It’s frustrating and can ruin your project. But you don’t need to be an engineer or have a degree in Chemistry to figure this out! The answer is simple, but the fix may not be so easy. If you’re in a situation where a bolt is spinning and it’s impossible to get a grip on the head, try inserting an object such as a wrench or screwdriver between the bolt and nut.

This will stop the spinning of the bolt so that you can tighten it by hand without having to use tools. This blog post walks through how to tighten a bolt that keeps spinning with different techniques like using WD-40, Vaseline, vegetable oil, or adding something heavy like nuts or bolts on top of the bolt until it finally tightens. Read on to know more information about this.

Summary: To solve a problem with a spinning bolt, follow these simple steps: 1. Check the fit of the bolt and make sure it is tight. 2. Use a wrench to turn the bolt until it is tight against the nut. 3. Repeat steps 1 and 2 until the bolt no longer spins.

10 Ways on How to Tighten a Bolt That Keeps Spinning:

1. Using Adjustable Wrench:

If you have an adjustable wrench, it will come in handy when turning the bolt, and the handle keeps rotating. If this happens, adjust your grip so that the teeth of the adjustable wrench are gripping on opposite sides of the head of the bolt. Tighten until snug to break torque.

You can make an adjustable wrench from a piece of wood and a hexagonal metal bar. This is similar to what bike mechanics use to tighten crank bolts, but you can easily make your own with just a piece of scrap lumber, a metal hex wrench (a 5mm will work), and some tape. First, cut a short piece of wood that is as wide as the bolt head.

2. Using Vise-Grips:

If you have a pair of vise grips, you can use them to loosen a bolt that is too big to fit in your adjustable wrench. Place the vise grips around opposite sides of the bolt head and pull until snug to break torque. If you don’t have vise grips, you can use a crescent wrench or pipe wrench instead if you cut a notch into the head of the bolt.

3. Using Pipe Wrench:

It will come in handy if you have a pipe wrench when the bolt head is too big to fit in your adjustable wrench or vise grips. If there is not enough space to rotate your pipe wrench handle more than 180-degrees, use your adjustable wrench or vise grips to hold the bolt head. Then, grip onto the pipe wrench handle with one hand and rotate it clockwise until snug. Then, rotate the pipe wrench handle clockwise another half-turn. If you are using an adjustable wrench or vise grips, hold them on the nut side of the joint. You may need to use your left hand to grip the frame to keep it from turning.

4. Cut the Bolt Off:

If you have a hacksaw, it will come in handy when the bolt is too long to fit your adjustable wrench or vise grips. If possible, try clamping onto the bolt with adjustable wrench/vise grips before cutting because this will keep it from spinning while sawing. Next, cut the bolt head off, leaving enough thread so you can grip with adjustable wrench/vise grips. Unscrew the nut from the bolt. Now that you have removed the nut, pull the broken bolt out of your pipe.

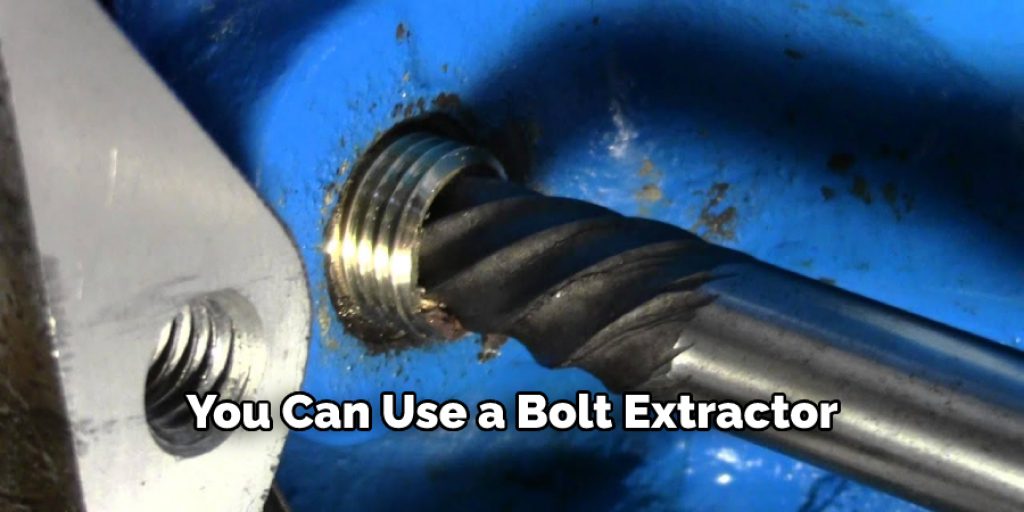

5. Use a Bolt Extractor:

If the bolt is too stripped or damaged for any of the tools discussed above, you can use a bolt extractor. Use a drill to make a hole into the center of the head of the stripped bolt and place the extractor bit on top.

Drill a hole into the stripped bolt until the extractor bit reaches the top of the threads. Grip the extractor with an adjustable wrench or vise grips and turn it counter-clockwise until the stripped bolt extracts itself from the hole.

6. Use an Easy-Out:

If the bolt is too stripped or damaged for a drill, you can try using an easy-out instead. Try finding a replacement of your stripped bolt with the same thread pitch, then center it on the stripped threads. Place the easy-out over the replacement bolt and tap into place with a hammer to break torque on a stripped bolt. Place the bolt into a vice and then use a wrench to turn the easy-out in the direction of the arrow until it comes out of the stripped bolt.

7. Use a Bolt Cutter:

If all else fails, it is possible to cut the bolt with an industrial bolt cutter. These are available at most hardware stores and will be able to cut through the least stubborn bolts. Once this is done, you can drill out the remains of the bolt with a drill bit that is only slightly larger than the size of the screw or bolt’s threading.

If you find yourself in a situation where you are unable to get the bolt out, it is possible to put a pressure washer on the bolt and use that to loosen it. This may damage the item that the bolt is holding in place and will likely have a significant amount of force used against it.

8. Use Pliers:

If you have a pair of needle-nose pliers on hand, you can use them to grip the bolt and tighten it. This will not work for all bolts, but if you can get two locking holes from one side of the nut to meet up with corresponding holes from the other side, this method may be possible.

However, this may not be optimal, as the locking holes can bend and deform over time. This is not a permanent fix, but it will help to ensure that the bolts are tight enough so that there is no danger of them falling out. If you do this, we recommend checking them periodically and replacing the wire if you notice any bending or distortion.

9. Use a Screw Extractor:

If you have a screw extractor, it will also come in handy when the bolt is too stripped or damaged for any tools discussed above. Use a drill to make a hole into the center of the head of the stripped bolt and place the extractor bit on top.

Drill until the extractor bit reaches the top of threads on the bolt. Next, grip onto the extractor with an adjustable wrench/vise grips and turn counter-clockwise until the stripped bolt extracts itself from the hole.

10. Use an Angle Grinder:

An angle grinder is a powerful tool that can remove paint from metal, plastic, or wood. These tools can also cut through concrete and steel with ease. For example, to tighten a bolt that has become stripped, the head needs to be removed from it. An angle grinder will allow you to grind down the end of a screw or bolt, making it possible to remove from a stripped hole.

Tips:

1. You must have a way to hold the bolt so that you can tighten it until it is secure.

2. You may need to remove the nut that the bolt is screwed into in order to get enough space between them so that you can apply pressure on the head of the bolt without having it slip off.

3. If you cannot tighten the bolt with your hands or another simple tool, try using a wrench or socket set. However, if the bolt and nut are rusted together, this may not work.

4. If the bolt is rusted together with something else, pour some lubricant over them to loosen the rust. Then try to tighten it again.

Conclusion:

Sometimes, a bolt can be tightened by hand. The palm of your hand is the perfect size to get an even grip on the head and handle it with enough force to tighten or loosen a fastener that has been stripped or rusted in place.

If you don’t succeed tightening this way, use the leverage from another angle using something like a wrench for added pressure when turning. Remember not to over-tighten bolts as they could break loose and fly off! We hope this blog post on how to tighten a bolt that keeps spinning has been helpful. Let us know your thoughts in the comment below!