How to Use a Torque Wrench Inch Pounds

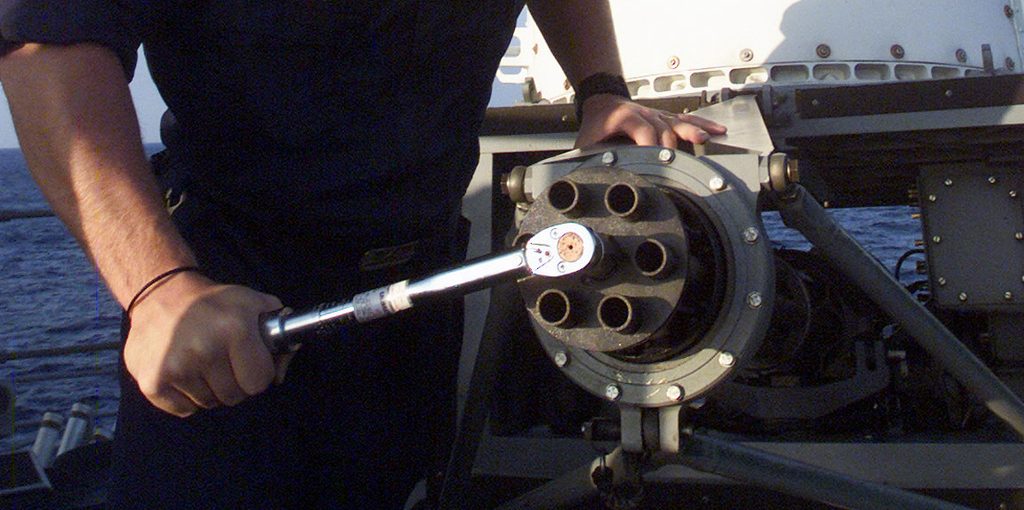

A torque wrench is a tool that provides the user with more accurate measurements of how much force they are applying to an object. Torque wrenches can be used on many different things, but their most common use is automotive. So if you’re looking for a way to make sure your car breaks down less often, it may be worth investing in one!

Torque Wrenches come in both inch-pounds and foot-pounds, which can make them challenging to understand at first. Inch pounds measure pressure applied using inches as a unit, while foot-pounds use feet as its unit measurement. This article will teach you everything you need to know about how to use a torque wrench inch pounds so that you don’t have any trouble from now on!

8 Reasons Why You Should Use a Torque Wrench Inch Pounds:

- The torque wrench in inch-pounds is an essential tool that can be used to tighten bolts and screws to the correct proportion of torque force. This increases the durability of the hardware, prevents nuts and bolts from loosening, and helps ensure moveable parts function correctly.

- There are several different types of torque wrenches to choose from. A click torque wrench in inch-pounds is always preferable; it’s accurate and can be used for most common tasks.

- The essential step is to make sure you choose the right size for your torque wrench in inch-pounds. There are 3/8-inch, 1/2-inch, and 12-millimeter sizes, along with many other options to choose from.

- A torque wrench in inch-pounds lets you hold the fastener at a specific angle, helping users avoid stripping or rounding heads. This can be accomplished by using locking extensions on some models.

- Be sure that the torque wrench you choose has a setting for “breakaway torque.” This will ensure that no damage is done if an over-tightened bolt or nut is encountered.

- Be sure to read the instructions when you get your torque wrench in inch-pounds. This will help prevent injury and ensure your tool works properly for a long time.

- When using a torque wrench in inch-pounds, apply it to the fastener until the handle arrives. This is the point where the bolt or nut is at its breaking point, and it should begin to rotate freely after that.

- Applications for torque wrenches in inch-pounds vary widely; there are also special applications for this type of wrench as well, including automotive fasteners and other objects that require relatively high tightening torque.

You Can Check It Out to Improvise a Wrench

Instructions: How to Use a Torque Wrench Inch Pounds

Here we have given the guidelines on how to use a torque wrench inch pounds.

Step 1:

Before using your torque wrench, make sure to adjust it (if applicable) to the proper setting for the size bolt or nut you’re using. This is done by turning the handle clockwise until you hear a click, then rotating it another half turn.

If there is no click, you should loosen the handle slightly and try again. You may also have to try again if there is a second click, then rotate another half turn.

Step 2:

Attach the socket that fits the bolt or nut to the end of the handle, then turn it counterclockwise to tighten it in place.

Step 3:

To apply the correct amount of force to your bolt or nut, slowly pull on the handle of the torque wrench until you feel a slight increase in resistance. If you pull too hard, the torque wrench will twist in your hand, and if you pull too lightly, it won’t provide an accurate measurement. With a little practice, you’ll be able to hit the optimal force level with each use.

Step 4:

After completing a project, you can repeat the process to double-check your work and make sure everything is securely fastened.

Step 5:

To avoid damaging the bolt or nut you’ve just fastened, hold onto the handle while loosening the socket with your other hand. This will prevent the torque from increasing and making it harder to remove.

Step 6:

Once you’re done using your torque wrench, be sure to release the pressure by turning the handle counterclockwise. Then, return it to its original setting. If possible, store it with a protective cover. Alternatively, you can store this tool in a pouch or bag for easy access next time.

Tips and Tricks:

- Small engines and motors are fragile, so they have to be handled with care. This means that it’s essential to use the right tools when you’re working on them. In doing so, you’ll make sure everything is in good working order and operate correctly.

- Torque wrench is a handy tool for tightening or loosening different parts. There are several types of torque wrenches of this kind, but the Inch Pounds type is the most preferable as they provide you a precise measurement of torque as they keep on clicking till it reaches the specified torque level.

- If you’ve never used an Inch-Pound torque wrench before, you’ll need to familiarize yourself with it. You can start by looking at the main components of the torque wrench. The knob has a scale on it that will tell you where the pre-set torque value is located.

- Now, loosen the fastener you want to tighten up by turning that knob in a counterclockwise direction.

- Do not use too much force when turning the knob, as this might affect the calibration of the torque wrench. Instead, try to turn it in a smooth and fluid motion, without any binding or resistance.

- Once you have loosened the fastener, place the torque wrench on top of it. Again, make sure not to put any gap between the fastener and wrench.

Things to Consider When Using a Torque Wrench Inch Pounds:

1. Check for Calibration

Most torque wrenches come with a calibration certificate from the factory. Make sure it complies with the ISO testing standards.

2. Select Proper Size

The right torque wrench for the job is essential to ensure that your mechanical work is up to par. Torque wrenches come in a range of measures, from 5-150 ft.-lbs., so you can find the perfect one for the task at hand.

3. Consider Your Needs

A torque wrench is a tool that helps you tighten or loosen a nut or bolt. There are two types of torque wrenches: standard and electronic. Standard torque wrenches require you to count the number of “clicks” it takes to reach the desired torque setting. Electronic units allow you to program specific settings into them, and they will alert you when the desired torque is reached.

4. Select a Good Location

An excellent place to store your wrench is on a magnetic holder, which allows it to be conveniently stored on any metal surface. This makes it easily accessible and keeps it from getting lost. This is a great idea to keep in the trunk of your car for quick access.

5. Do Not Over-torque Smaller Fasteners

Smaller fasteners such as screws or pins may not need as much force as a larger bolt.

6. Apply the Force Evenly

To ensure that the wrench applies even pressure, you should apply smooth and even application of power to the handle. Continue using pressure on the handle until you have reached the desired torque level. If it takes more than a few turns on a regular torque wrench, the fastener may have a problem.

7.Don’t Overtighten

Overtightening can cause damage to the fastener or its surrounding area.

8. Select the Right Size Sock

If you are attempting to attach a nut and bolt with a socket wrench, make sure that you select an appropriately sized socket that will fit over the fastener.

6 Benefits of Using Torque Wrench

- Helps prevent over-tightening, which could lead to unnecessary damage

- Prevents under-tightening, which could result in a loose bolt, resulting in loss of energy efficiency

- This applies only to the specific fastener type and size being used for ensuring the correct amount of torque

- Ensures that a bolt reaches a minimum required torque for proper installation

- Simple to use for First-Time users

- Ensures the highest quality of vehicle performance and safety

Conclusion

Torque wrenches are an essential tool for any mechanic, and knowing how to use a torque wrench inch pounds properly will ensure that you know what your car is doing. Whether you’re a novice or veteran, it’s essential to understand torque wrench usage in inch-pounds so that the right amount of force goes into tightening bolts on your vehicle.

With this blog post, we hope to help educate our readers about these tools and their importance and provide some helpful tips on using them correctly. We’ll also discuss when they should be used relative to other wrenches since there are many different scenarios where they come in handy!