How to Torque a Nut Without a Socket

You can torque a nut without a socket by using the back of your ratchet. The best way to do this is to use the handle of the ratchet as leverage and wiggle it while applying pressure with your hand on top of the head.

You will need to find an object that you can leverage, such as a large crescent wrench or screwdriver. It’s important not to force anything when doing this because you could break something! This blog post will show you how to torque a nut without a socket. So stick with this blog post till the end!

10 Ways on How to Torque a Nut Without a Socket:

1. Hammer a Nail Into the Nut:

Using a hammer, drive a nail into the side of the nut to hold your bolt in place. Then you can tighten the nut using your wrench.

2. Use a Screwdriver as an Extension:

If you don’t have any extensions handy, except for your regular box end wrenches, take a screwdriver and cut off the head of the screwdriver. Take out your socket, place it over the bolt like usual, and then put it on the screwdriver’s head. Tighten the nut with your wrench.

3. Use a Bolt and Spacers:

Instead of using a normal bolt, why not drill out some spacers, such as washers on either side of the nut, to serve as extensions for your socket wrench? This one works better on larger bolts or on smaller ones that have a lot of spacing.

4. Use a Socket Extension:

Just like you cut off the head of a screwdriver, do the same with your sockets. Put two extensions (spacers) on either side and tighten it with your wrench. This is better than using spacers because you can use any length socket instead of drilling out specific spacers.

5. Use a Plumber’s Extension:

Grab a plumber’s extension (again, washers can work) and thread it on your bolt like you would normally with the socket. Then tighten it down with your wrench. Sometimes this method is better than others, like when you need to make several turns at once because the extensions might not stay in place while staying locked onto the nut.

6. Put on Multiple Sockets:

If that’s the case, then just put on several sockets, at least two. Only use this method if you’re trying to apply a lot of torque to the nut because if you put too much force on the socket, it can crack.

7. Use a Big Socket:

Find the most multiple sockets you have and put it over your wrench to keep the bolt’s head inside it. Then tighten your wrench as usual, and this method will give you more torque than just using a regular-sized socket would.

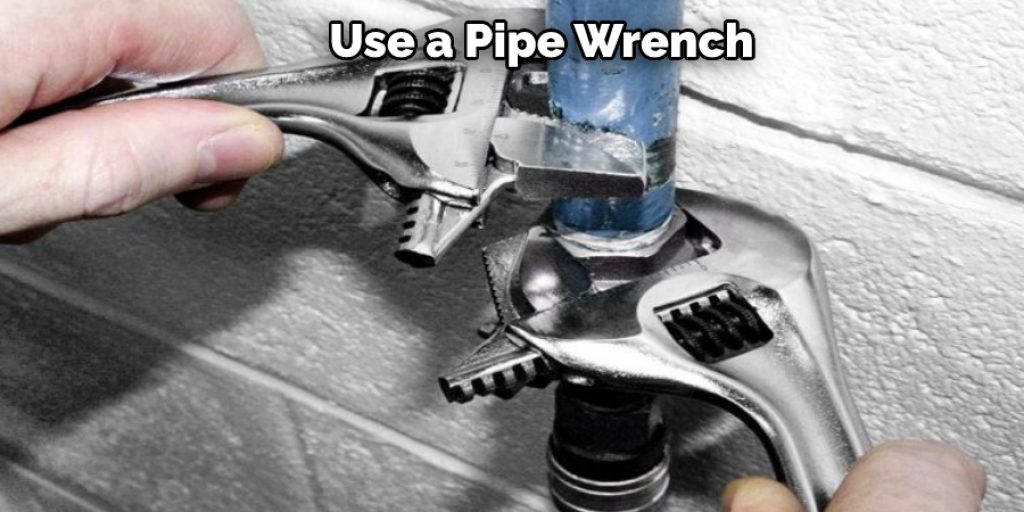

8. Use a Pipe Wrench:

Just as you would use a normal wrench or pliers to tighten bolts, you can also use a pipe wrench for those that have large flat areas on the outside to place your wrench upon. Again, this works best on larger nuts and bolts.

9. Use a Bench Vise:

Using the bench vise mechanism to give you more torque is an often-forgotten practice that will work for small or medium-sized nuts or bolts. Screw your socket onto the bolt, put it into your bench vise, then tighten down on it with your wrench.

10. Use Thread Locker Compound:

Instead of using your wrench to tighten your nut or bolt, place a thin layer of thread lock compound between the nut and the bolt. This method works well with all sorts of nuts and bolts because it gives them more resistance against coming undone.

Tips and Advice:

- Put the nut in a vice, and place the threaded rod in the nut.

2. Tighten down on the nut as hard as possible with a pair of pliers (leaving the threaded rod in it).

3. Attach an appropriate weight to the end of your wrench, and use it as a lever arm.

4. Once you hit your desired torque, tighten the nut more by spinning the threaded rod.

5. Finish with your wrench on the other side of the nut since some torque is always lost in transition!

6. Do not over-torque, or you will permanently deform both pieces of metal, be careful!

7. Use a torque wrench for small nuts and bolts if you want maximum accuracy.

Things to Consider When Torquing a Nut Without a Socket:

1) The strength of your arm and the torque you apply. The greater the torque applied, the less likely it will be to strip.

2) The diameter of your wrench will determine the maximum torque you can apply.

3) The longer your wrench, the more torque you can apply.

4) You must be aware that all the force is transferred to the nut, which may strip if too much force is applied.

5) The length of time you can hold a given torque will depend on the temperature you are applying it at.

6) Your movement speed will also affect your exertion time as an increased speed can lead to loss of control over the wrench and arm.

7) The nut size will affect how much torque you can apply.

What Can I Use if I Don’t Have a Torque Wrench?

A socket wrench set with a ½-inch drive ratchet wrench will allow you to apply proper torque. However, most sockets of this size aren’t designed to be torqued in a way that will provide an accurate reading, which means it’s important to have a torque wrench. Still, the torque wrench is an expensive tool that few home mechanics own.

In cases where a torque wrench isn’t available or would be prohibitively expensive to buy and use regularly, you can still correctly apply the necessary torque to small fasteners with nothing more than a bit of math and some trial and error.

Conclusion:

Several methods can be used if you need a way to torque a nut without using a socket. We recommend pushing your hands together or farther apart with your arms. Put one hand on top of the other, and then put all of your fingers below it. Push with all four fingers to bend them back onto themselves.

You may have also heard about placing two nuts against each other and twisting one with pliers placed over it-this technique is very hard to do but will work if done properly. We hope this blog post on how to torque a nut without a socket has been helpful. Let us know your thoughts in the comments below.