How to Tighten Cylinder Head Bolts Without Torque Wrench

Tightening cylinder head bolts without a torque wrench can be a tricky process. If done incorrectly, you could damage the bolts or the engine. In this blog post, we’ll show you how to tighten cylinder head bolts without torque wrench. Keep reading to learn more!

Some engine parts are more important than others. The cylinder head is one of these parts. It sits on top of the cylinders and houses the valves. If the bolts that hold it in place become loose, performance can be adversely affected. Luckily, there are a few ways to tighten them without a torque wrench. Read on to learn more!

What is a Torque Wrench?

A torque wrench is a specialized tool used for tightening bolts and screws to a specific tightness, known as torque. It measures the amount of rotational force applied to the bolt and indicates when the desired tightness has been achieved.

You might be wondering if it’s necessary to use a torque wrench to tighten cylinder head bolts. The answer is yes, it is highly recommended to use a torque wrench for this task. However, there are situations where one may not have access to a torque wrench or may need to make an emergency repair. In such cases, knowing how to tighten cylinder head bolts without a torque wrench can come in handy.

Why is It Important to Use a Torque Wrench?

Using a torque wrench ensures that bolts are tightened to the correct tightness, which is crucial in preventing them from loosening or breaking. It also helps distribute the pressure evenly across all bolts, reducing the risk of warping or damaging the cylinder head. In short, using a torque wrench helps maintain the proper functioning and longevity of your engine.

You may be tempted to just tighten the bolts as much as possible without a torque wrench, but this could be even worse. Over-tightening can cause the bolts to stretch or break, leading to costly repairs and potential engine damage.

Why Do You Need to Tighten Cylinder Head Bolts Without Torque Wrench?

There are a few reasons you might need to tighten cylinder head bolts without a torque wrench.

1. Prevent the Engine From Losing Compression

If the cylinder head isn’t properly secured, important engine parts can come loose. This can cause a loss in compression, which will lead to a decrease in power and fuel economy. So, it’s important to make sure the bolts are tight enough to prevent this from happening.

2. Avoid Damaging the Engine

Another reason to tighten cylinder head bolts without a torque wrench is to avoid damaging the engine. If the bolts are too loose, they can cause oil and coolant leaks. If they’re too tight, they can damage the threads in the cylinder head. So, it’s important to get the tension just right.

3. Save Time and Money

If you’re working on a car that doesn’t have a torque wrench, tightening the cylinder head bolts without one can save you time and money. You won’t need to go out and buy a torque wrench, and you can get the job done without having to borrow one from a friend or neighbor.

4. Accurate Measurement

Using a torque wrench is the most accurate way to measure the tension on the bolts. But if you don’t have one, there are other ways to get an accurate measurement. This is another advantage of tightening cylinder head bolts without a torque wrench.

5. Get the Perfect Fit

When you’re tightening cylinder head bolts without a torque wrench, it’s important to get the perfect fit. This way, you can be sure that the bolts are tight enough to prevent leaks and damage but not too tight that they damage the threads.

6. Easier Than You Think

Tightening cylinder head bolts without a torque wrench is easier than you might think. With a little patience and the right technique, you can get the job done quickly and easily.

Now that you know why you might need to tighten cylinder head bolts without a torque wrench, let’s take a look at how to do it.

Things You Will Need to Tighten Cylinder Head Bolts Without Torque Wrench

- Cylinder head bolts

- A torque wrench is not required but can be used for extra precision

- A socket or open-end wrench that fits the bolts snugly

- A length of pipe or another extension that can be used as a lever

- A friend (optional) to help stabilize the cylinder head while tightening

How to Tighten Cylinder Head Bolts Without Torque Wrench in 9 Steps

Step 1: Remove the Spark Plugs

The first step is to remove the spark plugs from the engine. This will help to relieve any pressure that may be building up in the cylinders and make it easier to remove the bolts. Be careful not to drop the plugs and damage them. You can use a spark plug socket to remove them. The spark plugs can be put back in later. The main goal is to get the head bolts off without damaging them. It’s worth taking the time to do so.

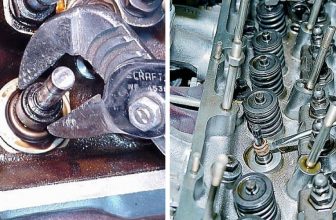

Step 2: Remove the Cylinder Head

Once the bolts have been removed, carefully remove the cylinder head from the engine. Be careful not to damage the gasket or the engine block. Make sure that the head is completely free from the block before proceeding to the next step. Otherwise, you may damage the bolts or the engine. But if you have a friend to help, they can hold the cylinder head steady while you work on tightening the bolts. But if you’re working alone, be careful not to put too much pressure on the head or damage it.

Step 3: Clean the Cylinder Head Bolts

Using a wire brush, clean the cylinder head bolts of any debris or rust. This will ensure that the bolts can grip the surface of the cylinder head properly. It can be difficult to clean the cylinder head bolts if they are rusted or corroded. In these cases, it may be necessary to use a chemical rust remover. You can also warm up the bolts with a heat gun to help loosen any rust.

Step 4: Insert the Cylinder Head Bolts

Using your fingers, thread the cylinder head bolts into the holes in the cylinder head. Make sure that the bolts are inserted evenly so that they will be tightened evenly. This can be difficult to do without a torque wrench, but it is possible. But again, having a friend to help can make this step easier. If you have a torque wrench, you can use it to get an initial reading of the tightness of the bolts. The torque wrench does not need to be set to a specific setting. It can just be used to get an idea of the tension on the bolts.

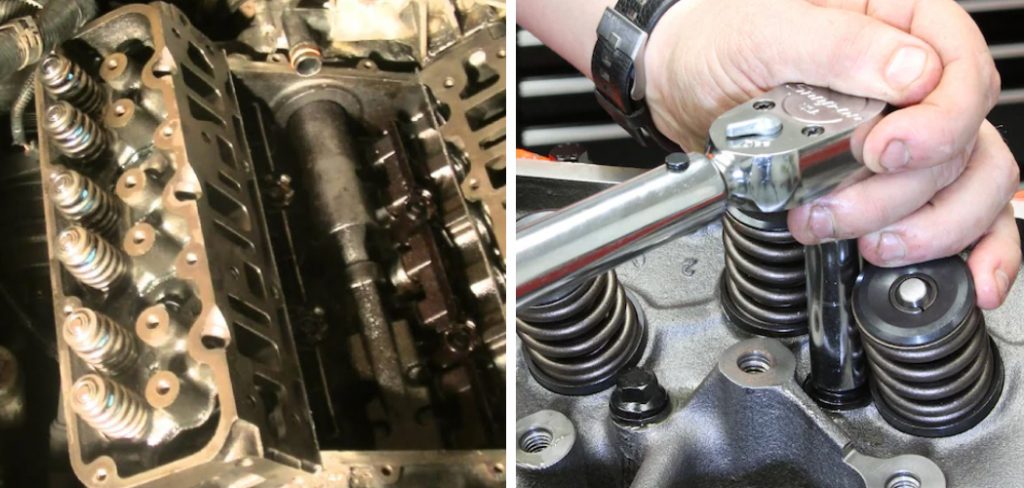

Step 5: Tighten the Cylinder Head Bolts

Once the cylinder head bolts are inserted, use a wrench to tighten them. Begin by tightening the bolts in the middle of the cylinder head first and then work your way outwards. Continue tightening the bolts until they are snug. Do not overtighten the bolts as this could damage the cylinder head. But you also don’t want to leave them too loose. You can use a torque wrench to get a reading of the tightness if you have one, or you can use the “hand-tight” method. This involves tightening the bolts until they feel about as tight as you would twist off a plastic lid on a jar.

Step 6: Reattach the Spark Plug Wires

Once the cylinder head bolts are tight, reattach the spark plug wires to the spark plugs. Make sure that the wires are properly connected so that the engine will start correctly. If wires don’t connect correctly, it may cause the engine to misfire. So you have to be extra careful when connecting them. You can also use an anti-seize compound on the spark plugs threads to prevent them from getting stuck in the future.

Step 7: Test the Engine

Once everything is buttoned up, it’s time to test the engine. Make sure there is plenty of oil in the engine and turn the key. The engine should start right up. Suppose it doesn’t go back and check your work. Once the engine is running, let it idle for a few minutes to make sure everything is working properly. The exhaust should be clear and the engine should sound smooth. But if you notice any issues, it’s best to take the car to a professional mechanic for further inspection.

Step 8: Check for Leaks

After the engine has been running for a few minutes, check for any leaks around the cylinder head. If there are no leaks, you can continue to use your car as normal. But if you do notice leaks, it’s best to take the car to a mechanic as soon as possible. Leaks in the cylinder head could lead to bigger problems if left unchecked. The sooner you get it fixed, the better. It’s also a good idea to periodically check for leaks after tightening the cylinder head bolts, just in case.

Step 9: Retighten Cylinder Head Bolts (Optional)

If you want to be extra cautious, you can retighten the cylinder head bolts after a few hundred miles of driving. This will ensure that they are properly seated and prevent any potential leaks in the future. It’s important to remember that tightening cylinder head bolts without a torque wrench may not be as precise as using one. It’s always recommended to use a torque wrench if you have one available, especially for high-performance or precision engines.

By following these steps on how to tighten cylinder head bolts without torque wrench, you can be sure that you’ll tighten your cylinder head bolts without torque wrench correctly and avoid causing any damage to your engine. Just remember to take your time and be careful, and you’ll be just fine.

Things You Should Be Concern About When Tightening Cylinder Head Bolts Without Torque Wrench

1. Engine Cold Before You Start

This is critical because you need to make sure that the engine is cold before you start to tighten anything. If the engine is hot, then you could potentially warp something and cause big problems. So make sure that the engine is cold before you even think about touching anything.

2. Right Size Bolt for Your Engine

You also need to make sure that you’re using the right size bolt for your engine. If you use a bolt that’s too small, it could strip the threads and cause big problems. If you use a bolt that’s too big, it could damage the engine. So make sure you know what size bolt you need before you start.

3. Properly Torque the Bolt

Once you have the right size bolt, you need to make sure that you torque it properly. This is where a torque wrench comes in handy. If you don’t have a torque wrench, you can usually find the proper torque specs in the service manual for your car.

4. Check Your Work

After you’ve torqued the bolt, it’s always a good idea to check your work. Make sure that the bolt is tight and that there are no leaks. If everything looks good, then you’re all set. It is very important to make sure you do these steps correctly when tightening cylinder head bolts without a torque wrench. Otherwise, you could cause serious damage to your engine.

5. Repeat as Necessary

If you’re not confident in your work, or if you’re just not sure, then it’s always a good idea to repeat the process. Just make sure that you’re careful and take your time. It’s better to be safe than sorry when it comes to working on your engine.

Some Essential Tips and Tricks to Tighten Cylinder Head Bolts Without Torque Wrench

Cylinder head bolts are one of the most important parts of an engine. They hold the cylinder head in place and help to seal it in the combustion chamber. Over time, these bolts can become loose and may need to be re-tightened. However, without a torque wrench, this can be a difficult task.

There are a few tips and tricks that can be used to tighten cylinder head bolts without a torque wrench.

1. Use a Socket and Ratchet

If you have a socket and ratchet set, you can use this to tighten the cylinder head bolts. Simply attach the socket to the ratchet and then insert it into the bolt. Tighten the bolt by turning the ratchet in a clockwise motion.

2. Use a Screwdriver

Another way to tighten cylinder head bolts without a torque wrench is to use a screwdriver. Simply insert the tip of the screwdriver into the bolt and turn it in a clockwise motion. It can be helpful to use a screwdriver with a long handle for added leverage.

3. Use Pliers

Pliers can also be used to tighten cylinder head bolts. Simply grip the bolt with the pliers and turn it in a clockwise motion. It is important to grip the bolt as close to the head as possible so that you do not strip the threads.

4. Use a Hammer

In some cases, it may be necessary to use a hammer to tighten the cylinder head bolt. Simply place the head of the hammer against the bolt and tap it gently with a clockwise motion. Be careful not to hit the bolt too hard or you could damage it.

5. Use an Impact Driver

An impact driver can be used to tighten cylinder head bolts in cases where other methods have failed. Simply insert the tip of the impact driver into the bolt and turn it in a clockwise motion. The impact driver will provide the necessary force to tighten the bolt.

By following these tips, you can easily tighten cylinder head bolts without a torque wrench.

Conclusion

While it is always best to use a torque wrench when tightening cylinder head bolts, there are times when you may not have one available. If you find yourself in this situation, follow the steps outlined in this blog post and you will able to know about how to tighten cylinder head bolts without torque wrench.

Cylinder head bolts need to be tightened in a specific sequence and with a torque wrench. If you don’t have access to a torque wrench, there are ways to tighten the bolts without one. You can use a ratchet and socket or an impact driver. Be sure to follow the proper sequence when tightening the bolts. Snug them up in stages until they’re all tight. These methods should only be used as a last resort if you don’t have access to a torque wrench.

You Can Check It Out To Adjust Camber Bolts

You Can Check It Out To Remove Crankshaft Pulley Bolt Without Impact Gun