How to Use Dowel Screws

Introduction

Many innovative techniques are used in modern-day carpentry. Among them, dowel screws are quite prominent. These types of screws do not have a conventional shape; instead, both ends are spiral for firm attachment between the legs of furniture. But many of us do not know properly about the exact manner of using these screws. For this reason, today, we will discuss some easy techniques on how to use dowel screws. This will be much beneficial for the beginners, and it will help accelerate your woodworking experience.

Procedure

Many processes can be implemented for using dowel screws. These screws are used as a core fastener for the furniture. There is no need for hardware when you are using dowel screws. Besides, these joint eliminates the requirement of extra nails, pins as well as staples. The assembly of such furniture is also straightforward. Thus, we have shortlisted some easy techniques that will enable a person to use the dowel screws. These steps are simplified below with proper explanation.

Method One

Step One : Operate the Dowel Screws

The first method of forming our list is a meaningful way to operate the dowel screws. This will help beginners get a proper hold on this equipment. Generally, dowel screws are manufactured to get extra attachment among the wood. And for this reason, there is no specific end for these screws. Both ends are made like screws, acting as an excellent fastener to join adjacent timbers and for perpendicular attachment too.

Step Two : Drill the Hole

The first step of this process is drilling the hole, before that it is necessary to select the dowel size. This is dependent on the type of joint that you are trying to place among the timbers. You can choose a comparatively higher diameter-based dowel screw for woods with more increased thickness. For timbers with lower thickness, you can easily select the normal diameter-based screes. This is dependent on the requirement of the user.

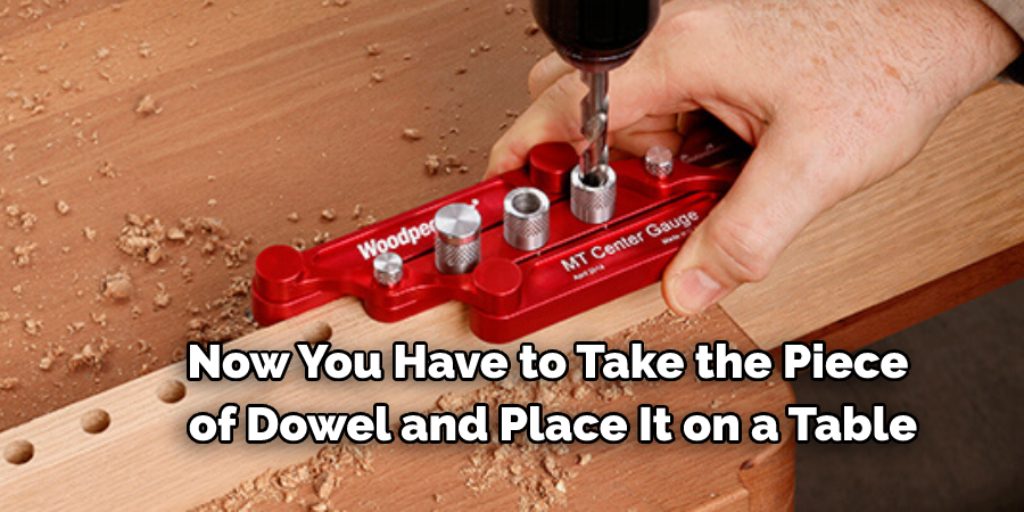

Step Three : Use a Clean White Cloth

Now you have to take the piece of dowel and place it on a table. Please use a clean white cloth to keep the screw in such cases, and there is much less possibility of missing the screw. Now you have to take a drill machine and select an accurate drill bit for the process. In such cases, the drill bit should be much less than the diameter of the dowel screw. This is much necessary for the proper attachment of the dowel to the wood.

Step Four : Kept the Drill Hole Size Lower

The hole that has been made using a drill machine should always be kept lower in size. This is done because the dowel screws are much thicker, and if the hole is not smaller than the diameter of the screw, then the point of a joint between the dowel and the timber will become loose. So the best way to get the correct connection is to drill a smaller hole and then using the drill machine and let the dowel screw bring out the best possible riveted joint among the timbers.

Step Five : Use Clamps to Hold the Furniture

Dowel screws are thicker than regular screws, so you will need to use more force to drill them in. To do this, you will need to clamp the furniture to your workbench so it doesn’t move.

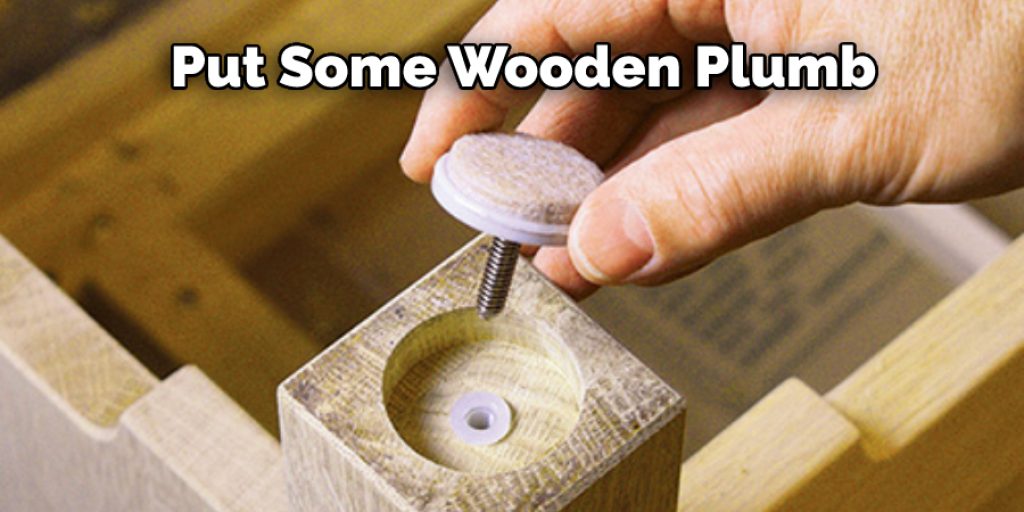

Step Six : Check the Level of the Table

It’s time to check the level of the table before you start working with the dowel. Place a level on the table’s surface and check the alignment. If the table is not level, put some wooden plumb to make it level.

Step Seven : Use the Wood Glue

Once the table is leveled, you have to take the drill machine and drill into a hole where you want to place the dowel. There will be an apparent creation of sawdust for the use of a drill machine. You have to remove the excess sawdust. Because this will hamper the future steps of the process. Now you have to take some glue and pour it in the guide hole that has been prepared. For this process, you must use the wood glue. This will help to make the process lot easier and without delay.

Step Eight : Use a Cordless Drill Machine

Dowel screws are always used in critical connection positions, so it’s important to have a cordless drill machine on hand to get proper access to all the furniture places. Use a dowel bit for the screwdriver to start drilling the dowel.

You have to dig it on the hole in which you have already used the wood glue, and you have to keep plugging until the final edge of the dowel disappears into the wood.

Step Nine : Let the Glue Dry

After you have drilled the dowel into the wood, you have to let the glue dry. Once the glue is dried, you can go for the finishing touches. Now you have to take the other legs of the furniture and drill in the same manner. After all, the drilling is done, and the dowel is attached correctly, you can let the glue dry and then turn the furniture it no the correct position. You have to check the furniture level, and after it is adjusted, you can remove the level, and your table is ready to use, and the dowel screws installation is finished.

Method Two

Step One: Take Measurement of the Wood

In this method, there will be a measuring tape requirement because the first step of this process is taking the precise measurement of the entire wood that you want to drill. It is better to use a drill mark for this task. This will help you mark the exact points, and you can quickly put ink in those places. Once the measuring and the marking of the drill bit are done, you can go for the next step. This step will include drilling along the measurement.

Step Two: Start Drilling the Hole

In order to dowel two pieces of wood together, you must first drill a hole into each piece using a dowel bit. It is important to make the holes narrow. Once the holes are prepared, you must make similar drilling on the adjacent wood, and then you have to make sure that both the parts are correctly aligned. This is the most critical aspect of the whole process. If the holes are not aligned correctly, then the dowel attachment cannot be adequately established.

Step Three: Apply the Wood Glue

After all the adjacent holes are aligned, you can drill the dowels in them, and then you have to apply the wood glue. This is much important because the shape of the dowel is quite a different form the conventional pins. For this reason, an adhesive is much essential, this will allow the dowel to settle down in the hole, and as a result, you can quickly get a firm connection. In this manner, you can easily use the dowel to establish a precise relationship between a table or furniture’s legs.

Precautions

Personal Safety

The process of using a dowel screw includes the use of automated machinery. This machinery requires electricity to run; besides, there is an ample opportunity of using a drill machine in this process. For this reason, as a concerned user, you must wear personal safety glasses and a face mask. This is important because there is always an eruption of sawdust in this process, which can be harmful to health. In these cases wearing a mask will surely help to reduce such unwanted threats to your health.

Guideline

Anytime you embark on something new, you can expect there to be challenges and complications. The same goes for using dowel screws. We’ve seen that different processes are involved in this case, and for the sake of our readers, it’s essential to know the exact process for doing it correctly. That’s why we suggest our readers check the guidelines for using this tool, to reduce the risks and increase the safety factor.

What are Dowel Screws Used For?

Dowel screws are used for various purposes, including connecting two pieces of wood or metal together. Dowel screws are designed with a threaded shaft and head, allowing them to be driven into the material securely and without the need for pre-drilling.

They are commonly used in furniture and cabinetry construction and in other applications such as installing door frames or window frames. Dowel screws provide an easy, secure way to join two pieces of material together without the need for additional hardware.

Frequently Asked Questions

Should I use dowels or screws?

There is no definitive answer to this question as it depends on the type of wood you are using and the application.

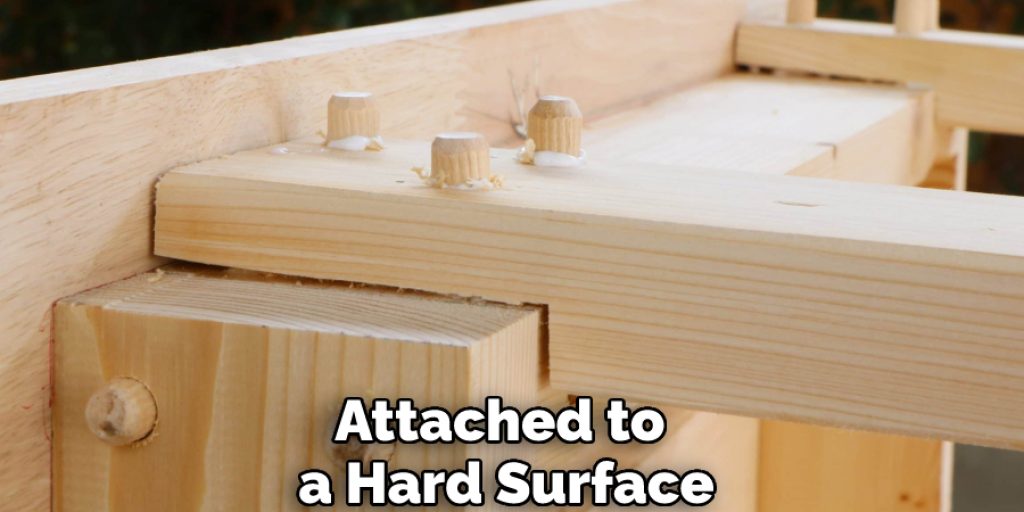

Dowels are generally used for applications where screws would not be ideal, such as when the wood needs to be attached to a hard surface. Screws can damage the wood over time if they are not properly installed.

Ultimately, it is important to use the right tool for the right job in order to avoid any potential damage or issues.

Can dowels be used outside?

Yes, dowels can be used outside, but it is important to use caution and follow the proper safety guidelines. When working with dowels, always wear protective gear, including gloves and a face shield.

Are dowels necessary?

Dowels are not necessary for most projects, but they can be helpful in a few cases. For example, using dowels to hold pieces of wood together while you are sanding or painting them will help keep the wood aligned and prevent it from warping.

Dowels can also be helpful when assembling furniture or cabinets because they keep the pieces together while you are screwing them in place.

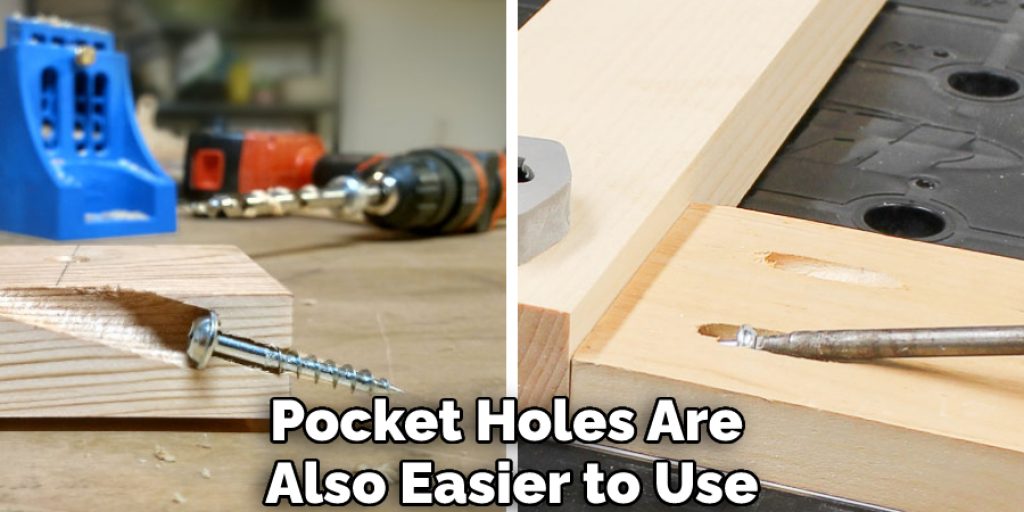

Which is stronger dowels or pocket holes?

Pocket holes are stronger than dowels because they hold more weight. Pocket holes are also easier to use because the screws can be inserted from the front or back of the board.

Conclusion

In conclusion, we hope that the techniques we have stated here will surely help use the dowel screws. These processes will much benefit the beginners who are newly acquainted with these screws. Besides, the people who are interested in DIY activities can also apply these processes. This is a great and effective way to enhance the personal skill of a person. Thank you for your precious time. Have a nice day!!

You may read also –