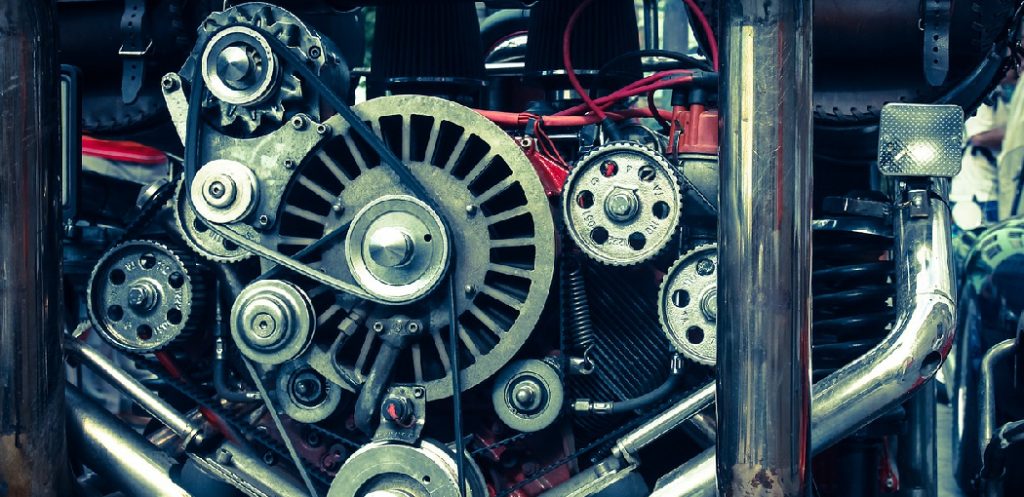

How to Align Pulleys on Serpentine Belt

Serpentine belts are an important part of keeping your car running smoothly. However, if the pulleys become misaligned, it can cause the belt to slip and create problems. In this blog post, we’ll show you how to align pulleys on serpentine belt so that everything runs smoothly. Keep reading to learn more!

Why It’s Important to Align Pulleys on Serpentine Belt?

The main reason it’s important to align pulleys on a serpentine belt is to ensure that the belt doesn’t slip. If the belt slips, it can cause problems, such as engine damage, decreased fuel efficiency, and more. So it’s important to take the time to align pulleys on the serpentine belt properly to avoid these issues.

Required Materials:

- Socket wrench set

- Ratchet

- Chisel

- Hammer

- Flathead screwdriver

- Tape measure

These are the basic tools to align pulleys on a serpentine belt. You can also use a wrench if you don’t have a socket wrench set.

A Stepwise Guide on How to Align Pulleys on Serpentine Belt

Step 1: Stop and Park the Car:

The first step is to park the car on a level surface and turn off the engine. Next, make sure that the parking brake is engaged.

Step 2: Open the Hood:

Now that you have the belt in hand, it’s time to start installing. The first step is to open the hood of the car. This will give you access to the engine and the belts. Be sure to open the hood before you start so that you don’t have to stop in the middle of the job.

Step 3: Locate the Pulleys:

Once you have the belt off, it is time to locate the pulleys. This can be tricky because they are often hidden behind other components. However, with a little patience, you should be able to find them.

There are typically five pulleys on a serpentine belt: one at the crank, one at the water pump, and three at the alternator. So the first step is to determine which of these is out of alignment.

Step 4: Adjust the Pulleys:

Now that you have located the pulleys, it is time to adjust them. This can be done with a wrench or a screwdriver, depending on the pulley type. If the pulley has a set screw, use a screwdriver to loosen it. Be sure not to overtighten the set screw, or you may damage the pulley. Once the set screw is loose, use a wrench to adjust the pulley. If there is no set screw, use a wrench to adjust the pulley’s position.

When adjusting the pulleys, keep them in line with each other. The belt should run straight between the pulleys. If the belt is crooked, it can cause damage to the belt and the engine.

Once the pulleys are adjusted, tighten the set screw (if there is one) or use a wrench to tighten the pulley. Be sure to use the correct size wrench for the pulley. You do not want to damage the pulley by using the wrong size wrench.

Test the belt by turning the engine on. The belt should be tight, and there should be no slipping. If there is slipping, adjust the pulleys again.

When you are finished, clean up any tools or debris, you may have created while adjusting the pulleys. This will help prevent accidents and injuries.

Step 5: Your Car Should Now Be Running Smoothly!

If everything looks good and your car is now running smoothly congratulations! You have successfully replaced your serpentine belt. Be sure to take care of your new belt, and enjoy your car’s newfound performance.

If, however, you still experience problems after completing these steps, it may be necessary to take your car in for professional help. Serpentine belts can be tricky to replace, and it’s always best to leave the job to the experts.

But with a bit of patience and these simple instructions, you should be able to do it yourself without any trouble. And remember, if you have any questions or concerns, don’t hesitate to ask a friend or family member for help or contact your local automotive technician.

Most Common Causes of Serpentine Belt Noise

If you are experiencing noise from your serpentine belt, it is most likely due to one of the following causes:

1. Wear and Tear:

The most common cause of serpentine belt noise is wear and tear. Over time, the belts will stretch and lose their elasticity, which can cause them to make noise. If your belt shows signs of wear and tear, it is time for a replacement.

2. Misaligned Pulley or Tensioner:

If the pulleys are misaligned, or the tensioner is not working properly, the belt may slip off. In this case, you need to realign the pulleys or replace the tensioner.

3. Improper Belt Installation:

There are a few ways in which you can install a serpentine belt. The most common way is the “over the top” installation. Another method is the “under the bottom” method. The third installation method is called the “cross the middle” installation.

4. Weather conditions:

Weather conditions can also affect how well your car runs. Extreme weather conditions, such as high temperatures or very low temperatures, can cause your car to run differently than it would in normal weather conditions. If you’re having trouble with your car running properly, check the weather conditions and see if they might be a factor.

5. Oil or Grease Contamination:

If you have an oil leak, the belt will become contaminated and need to be replaced. Likewise, the belt will also need to be replaced if you have a grease leak.

6. Defective Bearing:

If the serpentine belt is noisy, vibrates excessively, or slips, it may be caused by a defective bearing. In this case, the belt will have to be replaced. If you want to know more about how to align pulleys on serpentine belt, keep reading.

How to Diagnose Belt Squeal?

1. Check the belt for wear:

A belt that is worn out will often cause squealing noises. To check if your belt is wearing out, lift the hood of your car and look at the belt. If the belt is cracked, frayed, or worn down, it’s time to replace it.

2. Adjust the Tensioner:

The tensioner is responsible for keeping the belt tight, so if it’s not adjusted correctly, it can cause the belt to squeal. To adjust the tensioner, locate the tensioner pulley and use a wrench to rotate it clockwise until it’s as tight as possible.

3. Check the Pulley Alignment:

Serpentine belt pulleys should be in line, and the belt should be running in a straight line. You can use a straight edge to check this. If the pulleys are not in line, you can adjust them by loosening the bolts and moving them into position. Be sure to tighten the bolts again once the pulleys are in position.

4. Check the Pulleys:

Once you have the belt in place, it’s important to check the pulleys to make sure they are aligned. If they are not, you may need to realign them before the belt works properly. You’ll need to remove the belt again and adjust the pulleys as needed to do this.

5. Spray the Belt with Water – A 5-Minute Diagnostic

If you’re still not sure how to fix the problem, there’s one more thing you can do: spray the belt with water. This will help you determine if the belt is too tight or loose.

If the belt squeals when you spray it with water. If the belt doesn’t move when you spray it with water, it’s too loose if the belt moves a little when you spray it with water.

6. Remove the Belt from The Engine

There may be a few screws or bolts to be removed to take the belt off. Be sure to keep track of where each screw or bolt goes so that it can be put back in place later. Keep reading for more information about how to align pulleys on serpentine belt.

Frequently Asked Question

Can You Spray WD40 on Serpentine Belt?

I’m not sure if WD40 would be the best choice to lubricate your serpentine belt. I would recommend trying out a few different things to see what works best for you. Some people have successfully used vegetable oil, while others have used motor oil or silicone spray.

What Is a Serpentine Belt and What Does it Do?

A serpentine belt is a type of belt used in automotive applications. It is named for its sinuous path around the engine and other components. The serpentine belt is responsible for transferring power from the engine to the accessories, such as the alternator and air conditioning compressor; the pulleys must be aligned correctly to ensure that the belt functions properly.

What Can Be Caused by Misalignment of Drive Pulleys?

If the drive pulleys are not aligned correctly, it can cause a variety of problems, including:

- The belt may slip off the pulleys

- The belt may wear out prematurely

- The engine may not run properly

Conclusion

Now that you know how to identify the serpentine belt and understand its function, it’s time to learn how to align the pulleys properly. This is a crucial step in preventing damage to your car and ensuring that the belt functions. Next, we’ll walk you through the process of aligning the pulleys, so you can confidently complete this task on your own next time. Thanks for reading our post about how to align pulleys on serpentine belt.

You may read also How to Make a Belly Dancing Belt