How to Keep Carriage Bolts From Spinning

Carriage bolts are a particular type of bolt that is used in heavy-duty construction projects. The carriage bolt consists of a steel shaft and a large hexagonal head with an unthreaded shank below the head. The design of this type of bolt makes it ideal for when you don’t want the nut and washer to spin during installation, but what happens when they do?

Luckily, there are several ways to prevent this from happening. Just follow the simple steps mentioned in these blog posts on how to keep carriage bolts from spinning. First, use a center punch to mark the locations where you will drill your pilot holes into each piece that you’re fastening together. Then, drill out those holes so they’re exactly as deep as the length of your carriage bolts; if they aren’t deep enough, be sure to drill them deeper. Once you have done this, tap the carriage bolt into place with a hammer and then set it with a torch if necessary. Read on to learn more information!

What is a Carriage Bolt?

A carriage bolt, also known as a coach bolt, is a type of fastener that is commonly used in woodworking and other heavy-duty applications. It is characterized by its large domed head and square shoulder beneath the head. The unthreaded shank of the carriage bolt allows for easy installation without the need for a wrench or pliers to hold it in place. This type of bolt is commonly used to secure wood or metal pieces together, as the large head prevents it from pulling through the material.

Why Do Carriage Bolts Spin?

There are a few reasons why carriage bolts might spin during installation. One common reason is that the pilot holes have not been drilled deep enough, causing the shaft of the bolt to not have enough grip on the material. Another reason could be that the shank of the bolt is not square, which can cause it to spin while being tightened.

You may also experience spinning carriage bolts if the material being fastened is too thick or if the hole in the material is too large. This allows for more movement of the bolt, making it easier for it to spin while being tightened. Additionally, worn-out or damaged washers can also contribute to the spinning of carriage bolts.

It is important to address the issue of spinning carriage bolts because they can cause structural weakness in your project. If the bolt spins while being tightened, it may not be able to hold the materials together securely, leading to potential safety hazards or damage to your project over time.

Needed Materials:

Center Punch:

A center punch is a tool used to create a small indentation on the surface of materials, making it easier to drill accurate holes.

Drill:

A drill is necessary for drilling pilot holes in your materials. Make sure to use the correct size drill bit for your carriage bolts.

Hammer:

A hammer may be needed to tap the carriage bolt into place before securing it.

Torch (optional):

If your pilot holes are not deep enough, you may need a torch to set the carriage bolts in place. This will cause expansion of the material, providing a tighter grip on the bolt.

10 Ways on How to Keep Carriage Bolts From Spinning:

1. Use Lock Washers:

Carriage bolts are threaded at both ends, so after you insert them in the holes and hand-tighten them with a wrench or socket set, they should stay put. If not, use lock washers to prevent the bolt from turning and backing out. Lock washers feature an interlocking pattern that presses against the nut to prevent it from turning.

You can also use a lock nut with the carriage bolt, as it has a built-in locking mechanism that eliminates the need for washers. It is important to note that using lock washers or nuts can reduce the strength of the bolt, so it’s best to use them only when necessary.

2. Countersink the Holes:

If you’re working with softer wood than the bolt, such as pine or basswood, countersinking the holes is a quick and effective way of preventing any spinning. Your carriage bolts will have a flat bottom, so drill your countersink hole a little deeper than the length of the bolt. Bolt manufacturers recommend a countersink bit that’s 1/16″ larger in diameter than your fastener, but this may vary from one manufacturer to another.

It’s also important to note that countersinking the holes may weaken your wood, so use this method only when necessary. But if you’re using hardwood, countersinking the hole may not be necessary as it is already strong enough to grip the bolt.

3. Use a Solid Surface:

If you don’t have a countersink bit, you can use a solid surface that’s larger than the screw or bolt head. This could be a rubber backing that you can buy at the hardware store, an eraser, wood putty, or even some smashed-up chewing gum. A flathead screwdriver will usually do the trick on softwood, especially if it’s smaller than your carriage bolt head.

It’s important to use a solid surface when working with softer materials, as it helps distribute the stress and prevent any spinning. You can also use a slip-resistant mat or rubber gloves to grip the bolt while you tighten it.

4. Use a Reamer:

Reamers are designed to remove material from a hole. So after you drill the countersink, ream the hole slightly larger than the diameter of your carriage bolt head. This will prevent it from spinning, and because there’s a little friction between the bolt and the reamed hole, you’ll still be able to tighten it down with a wrench. Use a tapered reamer for best results.

You can also use a rotary tool, such as a Dremel, to ream the hole if you don’t have a tapered reamer. Just be careful not to enlarge the hole too much, as this could weaken your material.

5. Use Loctite:

If you’re working on an outdoor project, you can use construction adhesive to keep your carriage bolts from spinning. Others have reported success with silicone or polyurethane caulks as well. Just clean the hole out before applying the adhesive, place your bolt in it, and let it cure. This will create a strong bond between the bolt and the material, preventing any spinning.

You can also use thread-locking compounds, such as Loctite, to keep your bolts in place. These compounds are designed to prevent fasteners from loosening due to vibration or movement.

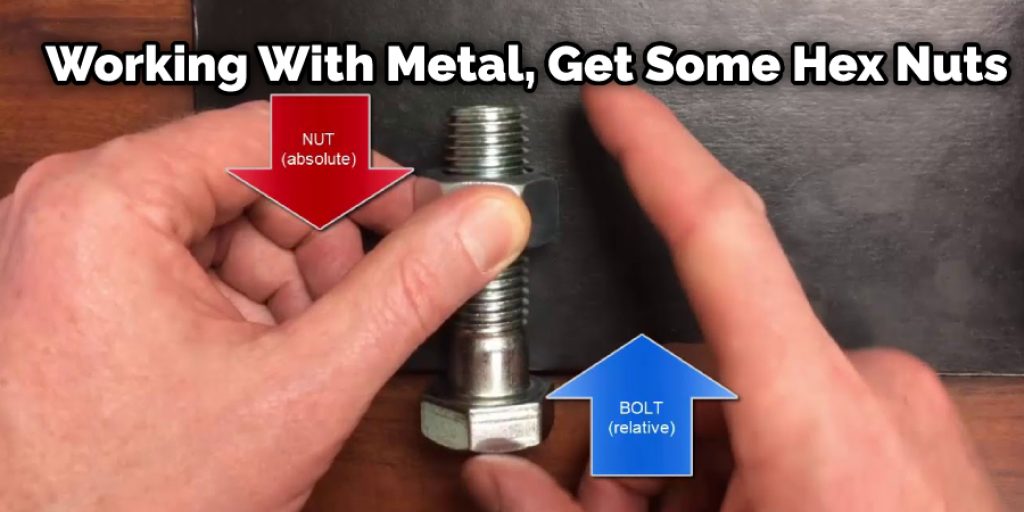

6. Use a Hex Nut:

If you’re working with metal, get some hex nuts that are slightly larger than the head on your carriage bolt and place them over the exposed threads of the bolts after they’re installed in your project. This will prevent them from spinning while still allowing them to be tightened down with a wrench or socket set.

The size of the hex nut will depend on the size of your carriage bolt, so make sure to get the correct size for best results. It’s also important to note that using a hex nut may not be aesthetically pleasing in certain projects, so consider this method carefully.

7. Use a Spacer:

If you’re working with metal, use a piece of rubber, plastic, tape, or anything else that’s slightly larger than the head of your carriage bolt to prevent it from spinning while threading it into the wood. If the hole is countersunk and reamed properly, the spacer should be flush with the surface of your project.

You can also use washers as spacers, but make sure they are slightly larger than the bolt head and inner diameter of your hole. This will prevent any spinning while still allowing you to tighten down the bolt.

8. Use a Rubber Pad:

Place a rubber pad or washer over the head of your carriage bolt and tighten it into the drywall, sheetrock, hardboard, masonite, plywood, exterior wall-board paneling, etc. This will prevent it from coming loose while you’re working on your project, but should still allow you to loosen up the bolt to take your project apart when you’re done.

You can also use a rubber pad or washer when working with softer materials, as it helps distribute the stress and prevents any spinning. Just make sure to get a rubber pad that’s slightly larger than your bolt head for best results.

9. Use Penetrating Oil:

If all else fails, try spraying some penetrating oil around the circumference of your carriage bolt before inserting it in the hole. This won’t prevent the bolt from spinning, but it should make it easier to remove after you tighten it down. Another option is to heat your carriage bolt with a torch and then spray the area around the threads and between the sheaves (or whatever part of your structure or project that’s holding the bolt captive) with penetrating oil. Let it soak for a while, and then try removing it with a wrench or socket set.

It’s important to be careful when using heat and penetrating oil, as they can be dangerous if not used properly. Always follow the manufacturer’s instructions and take proper safety precautions. Overall, there are many methods for preventing carriage bolts from spinning while working on a project. It’s important to assess the situation and choose the best method based on your materials, tools, and personal preferences.

10. Drill It Out:

If you’ve tried everything else, your carriage bolt is probably stuck in place pretty tight. If this is the case, you can drill it out with relative ease if you use a combination of lubricants (penetrating oil, dish soap, laundry detergent, cooking oil, etc.). Let the lubricant soak into it for a while before you start drilling. If there are metal shavings in your home (or on the top of your carriage bolt), use WD-40 to clean them out first. This should allow you to drill right through it without any trouble.

Following these tips and techniques should help you prevent your carriage bolts from spinning while working on your next project. Remember to always use caution when using power tools or heat, and always wear appropriate safety gear. Happy building!

Precautions and Safety Measures:

What you do from the time you enter a work area until you leave can have a considerable safety impact on your project. For example, when drilling holes for carriage bolts, keep the following safety tips in mind to protect yourself and others:

1. Always wear eye protection. It is too easy to lose an eye when working with power tools.

2. Don’t wear loose clothing or jewelry that could get caught in the drill, saw, or other tools. Loose ties, long-sleeved shirts with hanging sleeves, bracelets, and dangling necklaces are all risks to be aware of.

3. When drilling wood, always clamp your workpiece down securely before you start drilling. Be sure to clamp your wood down in a way that allows you to drill without the workpiece moving around on you.

4. If possible, remove any nails from the wood before drilling. The force of a rotating drill bit can drive the nail through your workpiece, creating a much larger issue than you would have had if you’d put in a carriage bolt without removing it.

5. Make sure that all power cords are out of your way and not draped over any benches or other work surfaces where tools could damage them.

Frequently Asked Questions:

Q: What is the Difference Between a Carriage Bolt and a Regular Bolt?

A: A carriage bolt has a round head and a square shank that fits into a square hole. This prevents it from spinning while being tightened down. Regular bolts have hexagonal or other-shaped heads and are used with nuts to tighten them down. It’s important to use the correct type of bolt for your project. You can also use a hex nut with a carriage bolt to prevent it from spinning.

Q: Can I Use a Carriage Bolt in Place of a Regular Bolt?

A: No, carriage bolts are not designed to be used with nuts. They are meant to be tightened into wood or other materials with their square shank preventing them from spinning. Regular bolts, on the other hand, are meant to be used with nuts for tightening. You should always use the appropriate type of bolt for your project.

Q: What is the Best Way to Tighten a Carriage Bolt?

A: The best way to tighten a carriage bolt is by using a wrench or socket set on the square shank while preventing it from spinning. You can also use pliers or vise grips if necessary, but be careful not to damage the bolt or use excessive force. It’s important to tighten the bolt securely, but also avoid over-tightening as this can damage the wood or other materials. It may take some trial and error to find the right level of tightness for your specific project.

Q: What if My Carriage Bolt Still Spins Even With a Rubber Pad or Washer in Place?

A: If your carriage bolt is still spinning, you may need to use a combination of methods such as using lubricants, heating the bolt, or drilling it out. It’s important to assess the situation and choose the best method based on the materials and tools available. Always take proper precautions and safety measures when working with power tools or heat.

Q: How Can I Prevent My Carriage Bolt from Rusting?

A: To prevent rust on your carriage bolt, you can use a rust inhibitor spray or apply a protective coating such as paint or clear nail polish. It’s also important to use galvanized or stainless steel bolts for outdoor projects or in areas prone to moisture. Regularly checking and maintaining your project can also help prevent rust from forming on your carriage bolts.

Overall, preventing carriage bolts from spinning while working on a project may require some trial and error, but with the right techniques and tools, you can successfully secure your carriage bolt in place for your project. So don’t let a spinning carriage bolt delay your progress – try these tips and get back to building!

Conclusion:

Carriage bolts are a standard fastener used in construction. These large, round-headed screws have been around for over 100 years and were invented to solve the problem of how to keep carriage bolts from spinning when they were tightened down with a wrench or screwdriver. However, there are some ways you can prevent this from happening.

We have already discussed them in these blog posts. So be sure to check them out! We hope this article has given you some insights on how to keep carriage bolts from spinning. If not, feel free to contact us for more information about this topic. Thank you for reading!

You Can Check It Out To Change Bolt Pattern Without Adapters