How to Remove Dried Ink From Silk Screen

For every painter, producing artwork and converting the image to T-shirts or other silhouettes are fulfilling activities. The silkscreen case, ink, blending sticks, and wet-wipe are prolonged by maintaining materials clear of silkscreen pigment during usage washing the screening instruments. The form of ink determines the process needed to extract the ink from the materials.

Instructions:

Method 1: Using Water-based Dyes

• During the application procedure, water-based dyes, mostly used for fabrics, typically dry quicker than most other forms of inks. During the next job, wiping screens with mild cleansing agents, gentle brushing, and water frees the equipment from ink, enabling you to recycle the products.

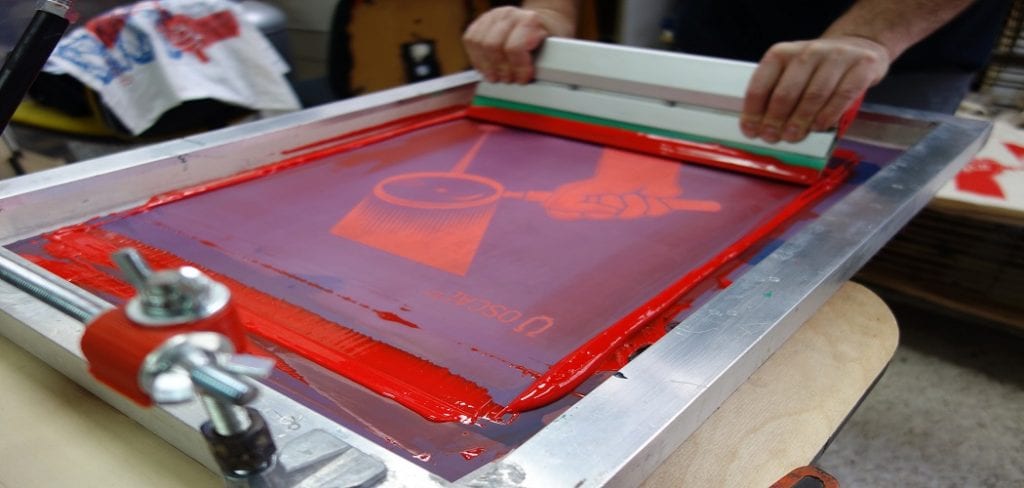

• By spinning the screen at a 45 ° angle, clear the remaining ink from the screen with a squeegee. Spinning causes the extra ink, related to it as the ink well, to fall to the twisted edge.

• Place the extra ink into the ink bottle from one side of the ink excellently. For the next idea, reuse the paint.

• To avoid some paint drops from ruining the area, hold the table filled with old papers or dropped sheets used for screening.

• Repeat the moving step from one side of the screen to the wrong sides of the squeegee. Once more, softly move some remaining ink into the ink well enough and drain the remaining ink bottle.

• Turn the screen over it with warmer water and continue the washing. Again, turn the screen forward. Cover the screen slightly with a gentle cleanser for dishwashing.

• By adding gentle pressure in a side-to-side movement, rub the detergent onto the screen. I was using a brush of smooth hair. In places where the ink has matted or hardened to stop the brush from reaching the screen, avoid putting formidable force. Begin repeating phases before the washing powder loosens the ink.

• Give a time of 24 hours for the screen to clear. To show some residual stained ink inside the mesh openings, keep the screen beside a clear illumination, related to it as the lamp check. The smoother the mesh fabric is, the more challenging it is to spot dried paint inside the screen. Please remember, when you put the color in the silkscreen, the dye in the next plan would not flow via the screen.

Method 2: Using Oil-Based and Plastisol Ink

Reduction of Oil-Based and Plastisol Ink

• From the following aspects, repeat the process.

• Onto a worn cloth, spill mineral spirits. Brush the fabric softly in a rotating and side-to-side direction on the screen. Drop a tiny quantity of paint thinner into the material when the color manages to settle between the mesh and rub softly into the frame.

• From the following aspects, continue steps. It is also difficult to clear oil- or plastisol-based pigments. To prevent paint drying or to cake onto the muslin cloth, it is wise to conduct this procedure following screen-printing directly.

Method 3: Extracting Ink From the Film

• Whenever it’s wet, extracting quite enough ink from the film as necessary can save a great deal of trouble further on. For more extended usages, scratch-off extra ink and rescue it.

• The next phase is to use an ink degrader to eliminate any signs of the ink. A “spray and clean” substance is an ink remover or ink degrader. It steadily dissolves plastisol, colorants, and adhesives in the inks because the solvent is released on the screen. The pigment will be less connected to the screen when the solvent is added and seems to come out.

• It is indeed safe to kindly clean and wipes the loose ink-free so that the ink has reduced its adhesion. However, it must wipe away reasonably fast; however, damp places can have to be scrubbed additional or need more ink remover.

• Emulsion Elimination: The strong adhesive-like material, which is susceptible to UV illumination, is the emulsion. Let control of Haze or Marks. Degreasing and then clean.

Some Helpful Tips and Suggestions:

1. Use a soft, dry cloth to blot the area as much as possible.

2. If the ink is still wet, use a hairdryer on the low setting to dry it.

3. Mix one part dish soap with two parts water, and gently dab the stain with a sponge or cloth soaked in the mixture.

4. Rinse the area with clean water, and blot it dry.

5. If the stain is still visible, try rubbing alcohol or vinegar.

6. Once the stain is gone, wash the item in cold water and tumble dry on low heat.

7. If the ink is still visible after all of these steps, it may be necessary to take the item to a professional dry cleaner.

Few Things to Consider When Removing Dried Ink From Silk Screen:

1. Use the Right Chemicals:

There are a variety of chemicals that can be used to remove dried ink from silk screens. However, it is important to use the right chemical for the job. Some chemicals can damage the screen or cause the ink to spread.

2. Clean Your Screens as Soon as Possible:

If you want to clean your screen, it is best to do it right after the ink has dried. This is because the longer the ink sits on the screen, the harder it will be to remove. Use a slightly damp cloth to wipe away any dried ink on the screen.

When cleaning your screens, be sure to use gentle pressure so you don’t damage them. Do not use any chemicals or solvents, as these can damage the fabric and affect future printing.

3. Be Sure to Keep Your Screens Tight:

To ensure optimal printing results, it is important to keep your screens tight. If they are not kept tight, ink will not be distributed evenly, which can cause problems with your prints.

If your screens are too loose, the ink will leak out from the sides. To prevent this, you need to keep the screens tight. You can do this by using a screen tightening tool or by using clamps.

4. Invest in a Good Pressure Washer:

If you do a lot of screen printing, investing in a good pressure washer is worth investing. This will make it easy to remove any dried ink from your screens. Be sure to read the instructions carefully before using the pressure washer. Pressure washing can be a little messy, so you may want to wear gloves and protective clothing.

5. Use Vinegar:

Vinegar can be used to remove dried ink from screens. Simply soak a cloth in vinegar and wipe down the screen. Be sure to rinse the screen with water afterward to remove any vinegar residue.

6. Try Soaking the Screen in Hot Water:

Another way to remove dried ink from silk screens is by soaking them in hot water. This will loosen the ink and make it easier to remove. However, be sure to use caution when using hot water, as it can cause burns.

7. Give Coldwater Rinse While Printing:

If you are printing with water-based inks, it is important to give the screen cold water rinse every few minutes. This will help the ink to bind with the fabric and prevent it from smearing.

Frequently Asked Questions

Will Screen Printing Ink Wash Out?

Screen printing ink may wash out if it is not properly cleaned. To clean screen printing ink, you will need to use a mild soap and water solution. Ensure to rinse the screen printing ink off thoroughly with fresh water to avoid any unwanted color bleeding.

Is Screen Printing Ink Permanent?

Screen printing ink is not permanent and should be removed as soon as possible to avoid any damage.

The ink used in screen printing is a water-based solution that dries quickly and can cause damage if left on the skin. The ink can also cause allergic reactions if it is exposed to sunlight or other sources of ultraviolet light.

To remove the ink, you will need to use a solvent such as acetone or alcohol. Make sure to wear gloves and eye protection when removing the ink, and avoid touching your eyes or face while doing so.

What Are the Procedures in Silkscreen Printing?

Silkscreen printing is a process that uses a screen to print images on a piece of fabric. The image is transferred to the fabric by pressing it through a fine-mesh screen. This process is used for printing labels, graphics, and other text-based materials.

There are several steps involved in silk screen printing:

1. Prepping the substrate: The substrate must be clean and free from any chemicals or oils that could interfere with the printing process. It should also be smooth so that the ink will adhere well to it.

2. Screening the image: The image is screened onto the substrate using a fine mesh screen. This step is necessary because it allows the ink to flow evenly and properly onto the fabric.

3. Printing the image: The printer applies pressure to the fabric with ink droplets, which transfer the image onto it.

Conclusion:

In conclusion, a few methods can be used to remove dried ink from silk screens. Each method has its own set of pros and cons, so it is important to choose the right one for the job at hand. To remove dried ink from a silkscreen, you will need ammonia and water. Mix the two in a spray bottle and lightly mist the ink.

Let the solution sit for about five minutes before using a rag or brush to clean off the ink. Be sure to rinse the screen thoroughly with water after cleaning to remove any remaining ammonia. Using the right solvent and following the proper steps makes it possible to remove even the most stubborn ink stains. We hope this blog post on how to remove dried ink from silk screen has been helpful. If you have any questions or want to know more then feel free to comment below!

You May Also Read –