How to Remove JB Water Weld

JB Waterweld is a type of welding epoxy that can be used for bonding metal surfaces. Many techniques can be used to remove JB water weld, but most require professional expertise. For this reason, today, we will discuss some easy methods to remove JB water. To learn how to remove it, there are two methods you can use.

You can attempt to remove it yourself, or you can call a professional to get the job done. In this guide on how to remove jb water weld, we will discuss both methods and provide some tips for successful removal. The ultimate goal is to help you get rid of JB water weld quickly and effectively.

What is JB Water Weld?

JB Waterweld is a two-part epoxy putty that hardens into a strong, durable bond. It can be used on various surfaces, including metal, wood, plastic, and more. This product is commonly used for plumbing repairs as it can withstand high temperatures and pressure. You can also use it for automotive, marine, and household repairs.

The main ingredients of JB Waterweld are epoxy resin and curing agent. When combined, these two components create a strong adhesive that can bond surfaces together. This makes it an ideal solution for repairing cracks, holes, and leaks in metal surfaces.

It is essential to note that JB Waterweld is a permanent adhesive and can be challenging to remove once it has cured. This is why it is crucial to handle this product with care and follow the instructions carefully.

Procedure on How to Remove Jb Water Weld:

Method One:

The first process we want to suggest to our readers is heating the weld. Applying adequate heat will be the easiest and quickest way to break the weld. For this, you can use a heat gun.

You can focus the fire on the weld more precisely with this method, and then the bond will be broken at a temperature of 600 degrees Fahrenheit. Chemical reactions will occur in the weld, and gradually, the weld will come off.

Method Two:

You can also use a grinding machine to detach the weld from the metal. For this, you will need an angle grinder and sandpaper. But before the process, you have to wear personal protective equipment. You must wear a face mask and goggles to prevent flairs from entering your body.

You have to apply a grinding machine to the bond, and gradually the weld will become naïve. Once the chemical begins to weaken, you have to use your hand and pull off the weld. Then you can use sandpaper to make the surface smooth.

Precautions While Removing JB Water Weld

- The only way to remove JB Water Weld is with a hard scraper. You can’t sand or wipe it off, and any other adhesive remover won’t work either, as the glue has multiple layers.

- Take care not to scratch your car’s paint while scraping; use masking tape on the surface before you begin removing the product.

- Try using two different scrapers: one made from plastic (to avoid scratching) and another that is metal but covered in cloth so that there are no scratches left behind. It might take some time for this process to go smoothly, but it will be worth it when you get closer to finishing!

- Plastic scraper (to avoid scratching) and metal, covered in cloth to prevent scratches.

- Masking tape on the surface before you begin removing the product.

- Remember to work in a ventilated area.

- Use water, lacquer thinner, or mineral spirits to keep the product from drying out and becoming resistant. Repeat as necessary until all of it is gone.

- Wear gloves; do not scratch your car’s paint while scraping.

What is a JB Water Weld?

The JB water weld is an adhesive sealant that has been around since the early 1900s. It’s often referred to as “JB Weld” or just plain “Waterworld,” and it can be used in many different situations, from garden hoses (to fix leaks) to car radiators. The weld has been around for so long that it’s become a household name and is trusted by professionals and beginners alike.

However, removing JB water weld can be a challenge. That’s why we recommend using the methods outlined in this guide to ensure a safe and effective removal process. Remember to follow all precautions, and if you are not confident in your abilities, it’s always best to call a professional for assistance.

Why Remove a JB Water Weld?

You might want to remove the JB water weld for several reasons. Maybe the material it was applied to has been compromised, or you’re just trying to prep it for future use on another surface (since it’s a good adhesive sealant). Either way, if you don’t have the right tools and supplies at hand, removing this type of glue can be an exercise in frustration.

You should also consider removing JB water weld if it has been damaged, as this can make it less effective in its bonding capabilities. In this case, removing the damaged portions and applying a fresh coat of JB water weld is recommended for optimal results.

Remember to always use caution when attempting to remove an adhesive like JB water weld, and be sure to follow safety precautions at all times. With the right techniques and knowledge, you can successfully remove JB water weld from any surface with ease. So, whether you need to reapply the weld o er want to switch to a different type of adhesive, now you know the best methods for removing JB water weld.

Which Scraper is Best for Removing JB Water Weld?

You can use a variety of scrapers and tools to remove JB Water Weld from surfaces. A Dremel tool with an abrasive cutting wheel will cut through the material quickly, but you will need to purchase one or more additional attachments for this purpose.

You may succeed using various other blades, including metal files and hobby knives. The hardest part is often removing the adhesive residue left behind when trying to scrape off all traces of JB Water Weld; it’s best to carefully sand down these areas beforehand so they are not too rough on your hands while scraping the surface clean.

In addition, keep in mind that some plastics may be affected by certain solvents used during removal efforts (such as acetone and paint thinner). Please test a small, unobtrusive material area beforehand to ensure that it will not become damaged or discolored.

Do You Need to Use Professionals?

While removing JB water weld can be a challenging task, it is possible to do it on your own with the right tools and precautions. However, if you are unsure about the process or don’t have the necessary equipment, it may be best to seek professional help.

Professional technicians have experience in dealing with various adhesives and know the safest and most effective methods for removal. They also have the proper tools and equipment to ensure a thorough and efficient removal process.

Moreover, seeking professional help can save you time, effort, and potential damage to the surface where the JB water weld is applied. So, if you’re not confident in your abilities or unsure about the safety precautions involved, it’s best to call a professional for assistance in removing JB water weld.

You can also reach out to the manufacturer for guidance on specific removal techniques and products that may be more suitable for your situation. In any case, always prioritize safety and follow proper procedures when handling adhesives like JB water weld.

How Much Could It Cost?

The cost of removing JB water weld will depend on a variety of factors, such as the amount of adhesive applied, the surface it was applied to, and whether or not professional assistance is needed.

If you attempt to remove it yourself, the cost will mainly be for the necessary tools and supplies. However, if professional help is required, the cost may include labor fees in addition to the cost of materials. It’s best to consult with a professional beforehand to get an estimate of the potential costs involved.

The cost of not removing JB water weld properly can be even higher, as it may damage the surface or compromise the effectiveness of future adhesives. So, investing in proper removal methods and seeking professional help if needed is ultimately a more cost-effective option.

The exact cost will vary depending on your specific situation, but it’s important to consider the potential costs of not properly removing JB water weld. In the end, it’s worth investing in the right tools and techniques for a successful removal process. So, if you’re facing a challenge with removing JB water weld, make sure to follow this guide for safe and effective results.

What Should Safety Rules Be Followed While Removing JB Water Weld?

- Use a respirator or mask for protection against toxic fumes. If you don’t have this, use an air-purifying canister (APC) to filter out the noxious gases and vapors created by JB Water Weld.

- Remove all ignition sources before applying heat, such as cigarettes, open flames, etc. Heat should be applied below at an angle, not over 30 degrees. Applying the heat too high up will cause failure due to dripping molten metal onto combustible materials, which may ignite, leading to fire hazards or worse explosions in some cases. Hence, it’s best not to apply heat until after removal has been completed using nonmetallic tools only.

- Do not try to remove the adhesive by simply scraping it off with a sharp blade or metal chisel! Sharp blades can be hazardous, and metal chisels may damage your equipment.

- Use only suitable cutting tools for this job that are made from durable materials like steel (hardened) and tungsten carbide inserts on them, if possible. The best way to do this is to use several different techniques for the best results; each will have its drawbacks.

- Protect your eyes with a pair of safety glasses or goggles while working with sharp tools.

- Be cautious about breathing toxic fumes caused by JB Water Weld removal efforts. Hence, it’s advisable not to work in an enclosed area without proper ventilation.

- Use water, lacquer thinner, or mineral spirits to keep the product from drying out and becoming resistant. Repeat as necessary until all of it is gone.

- Wear gloves; do not scratch your car’s paint while scraping.

- Remember to work in a ventilated area and follow safety precautions at all times when removing JB Water Weld. If you are unsure of the proper techniques or do not have the appropriate tools, it’s always best to seek professional assistance. Safety should always be a top priority when working with any type of adhesive.

Frequently Asked Questions:

Q: Can Jb Water Weld Be Applied to Wet Surfaces?

A: Yes, this adhesive can be applied to wet surfaces, making it ideal for quick repairs in emergency situations. However, the surface should still be as clean and dry as possible for best results. You should also keep in mind that the adhesive may take longer to fully cure when applied to a wet surface. You may need to apply a second layer after the first one has dried for optimal bonding. The surface should also be able to hold the weight of the adhesive without it sliding off or dripping down.

Q: Can Jb Water Weld Be Painted Over?

A: Yes, you can paint over JB water weld once it has fully cured. However, keep in mind that some paints may not bond well with this type of adhesive, so it’s best to test a small, inconspicuous area first before painting the entire surface. The surface should also be properly sanded and cleaned before painting for optimal adhesion. You may also need to use a primer specifically designed for bonding with this type of adhesive.

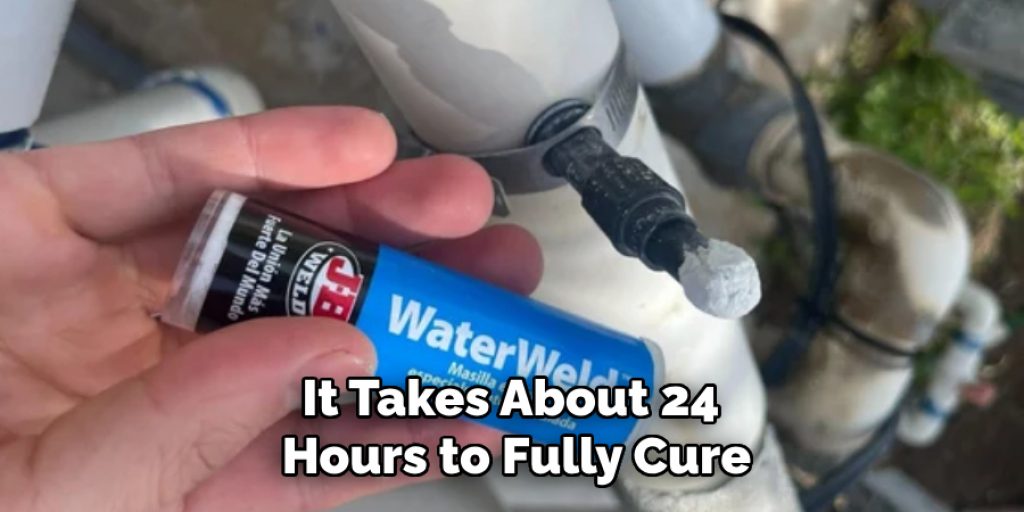

Q: How Long Does Jb Water Weld Take to Cure?

A: The curing time for JB water weld varies depending on factors such as temperature, humidity, and the thickness of the applied layer. Generally, it takes about 24 hours to fully cure at room temperature. However, colder temperatures or higher humidity levels may prolong the curing process. It’s best to refer to the product instructions for specific curing times and conditions. It’s also recommended that the adhesive be allowed to cure for longer than the instructed time for better bonding strength.

Q: Is Jb Water Weld Safe for Food Contact?

A: No, JB water weld is not safe for food contact as it contains harmful chemicals that can leach into food. Always use caution when applying this adhesive near areas where food is prepared or consumed. If you are using it in a location that may come into contact with food, make sure to thoroughly clean the surface before and after applying JB water weld. It’s also recommended to use a food-safe adhesive for any repairs in these areas.

Q: Can I Use Jb Water Weld to Repair Piping or Plumbing?

A: Yes, JB water weld can be used for piping and plumbing repairs, but it’s important to ensure that the surface is completely clean before applying the adhesive. Any residue or moisture may prevent a strong bond from forming. It’s also recommended to use a clamp or hold the repaired area in place for at least an hour to ensure the adhesive has fully bonded. If the piping or plumbing is under pressure, it’s best to seek professional assistance for repairs to avoid any potential hazards.

Q: How Can I Remove Jb Water Weld From My Skin?

A: It’s important to wear gloves when handling JB water weld as it can be difficult to remove from skin once it has cured. If some adhesive gets on your skin, immediately wash the affected area with soap and water. You can also use a petroleum-based product such as baby oil or mineral oil to break down the adhesive before washing it off with soap and water. Avoid using any harsh chemicals or solvents on your skin as they may cause irritation.

Overall, it’s best to take precautionary measures and avoid getting JB water welded on your skin in the first place. So, b e careful and always wear gloves when handling this adhesive to prevent any potential skin irritation or accidents. As a reminder, safety should always be a top priority when working with any type of adhesive. If you have any concerns or questions about using JB water weld, it’s best to seek professional assistance for the proper techniques and safety precautions. Stay safe and happy repairing!

Conclusion

Lastly on how to remove jb water weld, we hope the methods we have stated here will help remove the JB water welds. We have shortlisted these techniques more, making them easily understandable to our readers. The beginners can get the best result out of these processes, and those who are more into DIY activities can benefit from these techniques. Thank you for your time. Have a nice day!

You may also read – How To Make A Plasma Cutter From An Arc Welder