How to Sharpen Plastic

Introduction:

Plastic is a synthetic or semi-synthetic material commonly used to manufacture goods. Plastics can be produced from “monomers” such as propylene and styrene, which are small molecules that link to form long chains called polymers. The term polymer is derived from the two Greek words: ‘polus’ meaning many or several, and ‘meros’ meaning parts.

Thus, it connotes a substance of many units bonded together – often in large numbers – to form an extended chain. The basic unit is called a monomer; the polymer is formed by combining monomers with heat and pressure in a process known as polymerization. In this article, I will discuss how to sharpen plastic. So let us get started.

Summary: If you have a sharp plastic object, such as a ruler or knife, you can sharpen it by using a whetstone. Whetstones are small, flat pieces of stone that have a fine grit on one side. You use the coarse grit side to sharpen the blade, then use the fine grit to polish it.

Why is Sharpennign Plastic Necessary?

There are several reasons why you would have to sharpen the plastic. The first one is that it becomes useless if it gets chipped off. Another reason is that its original shape might get distorted after repeated usage. So, for these reasons, this guide on sharpening plastic will come in handy.

While sharpening these tools, the most important thing to remember is not to get carried away by pressure or speed. If you do, your tool will either end up with a sharp edge but smooth surface, or vice versa – a very rough edge but extremely sharp. To avoid this, sharpening must be balanced, smooth, and consistent. Also, remember that it’s better to sharpen on a rough surface rather than a hard surface. We recommend using whetstone or ceramic for this purpose.

Step-wise Guide on How to Sharpen Plastic:

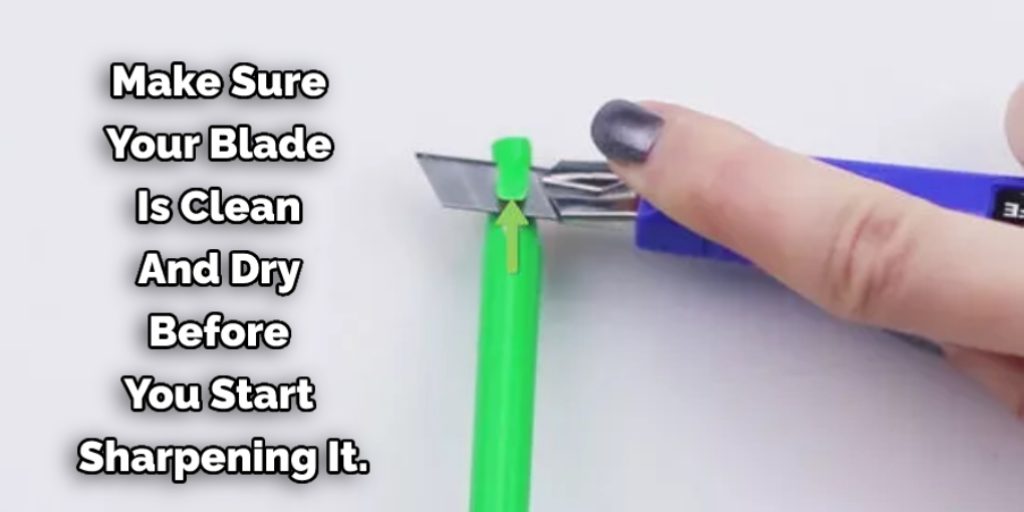

Step-1

Make sure your blade is clean and dry before you start sharpening it. It’ll ensure good friction between the blade edge and stone while you’re sharpening. After washing it off, the water from your hands can also mess up with sharpening if there is any water leftover on your knife or tool. If you are working with the straight-edged tool, place its body at 90 degrees to the cutting board to avoid getting cut accidentally while sharpening.

Step-2

Determine the ideal angle for sharpening your blade. Most tools usually have around 12 degrees on each side or 10-20 degrees on each side if you want a very sharp edge. You can also use a 15-degree angle if you want to retain your tool’s original shape.

Step-3

Hold your knife at its base (bottom). Use as much pressure as you can without sacrificing speed. Start applying a small amount of pressure and increase speed continuously till you get a smooth, balanced edge. Otherwise, if you apply more pressure first, then try speeding up later when the tip gets dull, there is a chance that your whole blade might end up with a rough surface instead of getting a smooth finish.

Step-4

After making an initial pass on one side, flip your knife over and make a pass on another side to get a mirror finish. This is the most important step, so don’t skip it!

Step-5

After you’re done with the first two steps, keep your blade in a vertical position and slide down from tip to bottom along the edge to make the first few strokes on both sides of the tool. It’s called honing. Repeat it twice (for better results). Make sure to use a small amount of pressure, around 20-30% as much as you used while sharpening.

If there are any burrs left after honing, remove them using a smooth stroke against a stone or hard surface. Repeat the same few steps till friction feels even across the blade & whetstone. You’re now done with sharpening.

Step-6

Polish your blade by performing a few strokes against the whetstone in the opposite direction. Don’t forget to keep honing and polishing your tool from time to time for many years of smooth and efficient usage!

Precautions While Sharpening Plastic:

a) Use light pressure when sharpening plastic

b) Always use fresh water to wet the abrasive surface

c) Never apply heavy pressure on the tool while grinding down a rough edge.

d) Never leave the blade exposed for long periods of time in between sharpening or polishing sessions, as doing so will damage it. Make sure you cover your blade with a cap or sheath every time you’re not using it.

e) If filing down a large amount of material at once, stop periodically and check your progress to prevent overheating (melting) your tools, as this may cause them to warp or crack into pieces! A good rule of thumb is to perform only one pass per minute when removing a lot of material at once, keeping a firm grip on the blade’s handle, and applying as little pressure as possible so that it doesn’t slip out of your hand. Also, try using sandpaper or an emery board to flatten down rough spots, perhaps after you’ve finished grinding with a Dremel to create a smoother edge.

f) When sharpening blades covered in plastic coatings, take care not to cause damage by over-grinding/polishing away too much material from the surface. If there are any humps or uneven surfaces on your blades after they’ve been ground down, use a large flat leather or rubber block to even them out instead of continuing grinding/polishing.

Frequently Asked Questions

Can You Make a Sharp Knife Out of Plastic?

It depends on the type of plastic and how sharp you want your knife to be. However, if you use soft plastic like a water bottle, it is impossible to make a sharp knife.

If you use a harder plastic like a container or bag, you can try cutting the plastic into small pieces and then shaping them into a knife. Be sure to use an appropriate tool, such as an X-Acto knife or a craft knife.

Can G10 Be Sharpened?

Yes, G10 can be sharpened. However, it is important to follow the correct procedures to avoid damaging the blade.

There are a few things that you need to keep in mind when sharpening G10:

1. Use a sharpening stone at least twice as wide as the sharpened blade.

2. Hold the blade at a 20-degree angle and sharpen from the spine towards the edge.

3. Be sure to use a light touch and take your time to sharpen the blade evenly.

Why Are Ceramic Knives So Sharp?

Ceramic knives are so sharp because they are made from a very hard material and do not rust. Ceramic knives also have a high resistance to rust, which means they will stay sharp for a long time.

Conclusion:

I hope this article has been beneficial for learning how to sharpen plastic. Ensure all the precautions. Thank you, and have a nice day!

You may also read – How to Sharpen a Dull Needle