How to Stretch a Truck Frame

Did you know that a truck frame can be stretched? This process is often used to increase the amount of cargo space in a truck. While it is not an easy process, it can be done with the right tools and instructions.

If you’re going to stretch the frame on your truck, there are a few things you need to keep in mind. In this post, we will walk you how to stretch a truck frame. We will also provide tips on how to do it safely and effectively. So, if you are looking to add some extra cargo space to your truck, read on!

Assembling a truck chassis is a daunting task. The welders, fabricators, and mechanics who do it every day have special skills. But what if you’re not a welder or a mechanic? What if you need to stretch the frame on your truck? It can be done, but it’s not easy. However, some companies specialize in stretching truck frames. These companies have the experience and the know-how to get the job done right.

What Does It Mean to Stretch a Truck Frame?

The process of stretching a truck frame is essentially lengthening the frame to create a longer wheelbase. This is done by adding material to the middle of the frame, which increases the distance between the front and rear axle. A stretched truck frame can give your truck a more aggressive look and improve its off-road performance.

Step by Step Process on How to Stretch a Truck Frame:

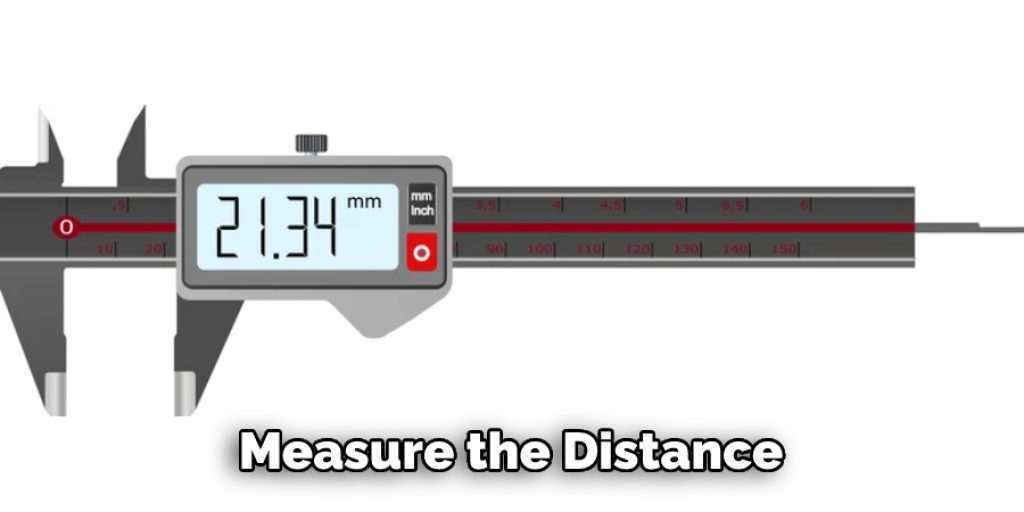

Step 1.Measure the Distance:

Measure the distance between the front and rear axle of your truck. This is the “stretched” measurement. The easiest way to do this is to measure from the center of the front axle to the center of the rear axle are your truck is sitting on level ground.

Step 2. Cut the Frame Rails:

Cut the frame rails at the desired stretched measurement using a cutting torch. It is important to make sure that the cuts are perpendicular to the frame rail. First, make a cut at the front of the frame rail. Then, make a second cut at the rear of the frame rail.

Step 3. Reinforce the Frame Rails:

Weld in some heavy-duty reinforcement plates to the inside of the frame rails. This will help to prevent the frame from racking under the added stress of the longer wheelbase. You can use some 1/4″ or 3/8″ thick steel plate for this.

Step 4. Install the Stretch Kit:

This is where the actual stretching of the frame will take place. Follow the instructions that come with your kit to install it properly. Most kits will require you to weld new frame sections in place.

Step 5. Weld in the Stretcher Plates:

Weld in a stinger plate at each of the cut ends of the frame rails. These plates will help to support the frame when it is stretched. Next, weld in a 4” x 6” x 1/2” plate at the center of the frame. This will be the starting point for stretching the frame. Now, weld in two more 4” x 6” x 1/2” plates at the desired width of the frame. These will be the end points for stretching the frame.

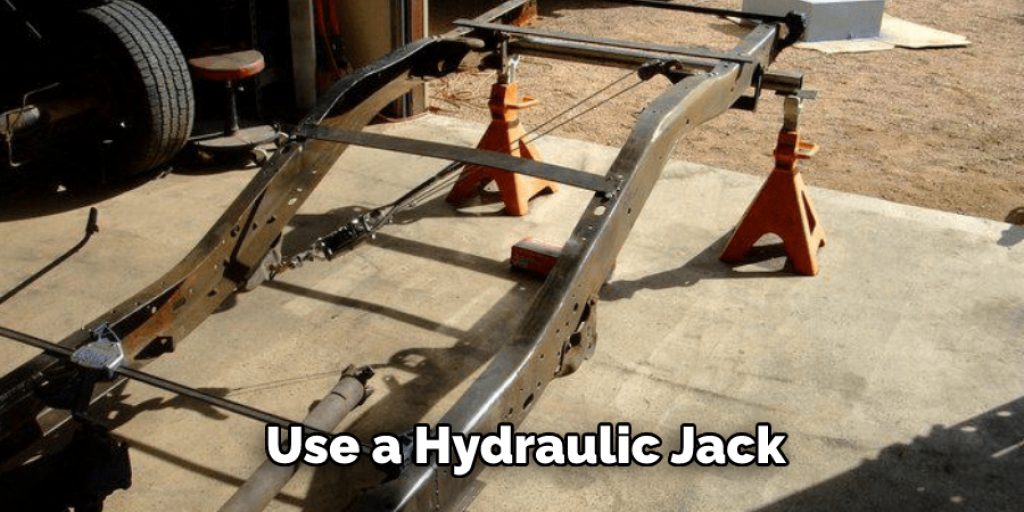

Step 6.Stretch the Frame Rails:

Using a hydraulic jack, stretch the frame rails until they are the desired length. First, jack up the truck’s front end until the tires are off the ground. Next, place the jack under the center of the frame rail and slowly raise it until the frame rail is at the desired height. Then, do the same thing to the rear frame rail. Make sure to check the alignment of the frame rails regularly to avoid damaging them.

Step 7. Install the New Body:

Once the frame is the correct size, you can install the new body. Start by attaching the front fenders and then work your way back. Be sure to use plenty of bolts and nuts to keep everything secure. You don’t want your new truck coming apart at the seams!

Tips and Warnings on How to Stretch a Truck Frame:

Tips:

- Always use a jack to support the frame while stretching it.

- If you are using a welder, be sure to have proper ventilation and take all safety precautions.

- Use an angle grinder to remove any paint or rust from the frame before stretching it.

- Always measure twice and cut once when cutting the frame.

Warnings:

- Do not overstretch the frame, or it could break.

- Be careful when using a welder or angle grinder around the frame.

- Make sure the frame is completely cooled before cutting it.

How Much Does It Cost to Stretch a Truck Frame?

The cost of stretching a truck frame will depend on the severity of the frame damage and the size of the truck. A small truck may only need a few hundred dollars worth of repairs, while a large truck could require several thousand dollars in repairs. The best way to determine the cost of your frame repair is to consult with a qualified mechanic or body shop. They will be able to give you an accurate estimate of the repairs needed.

Conclusion:

Frame stretching is a popular way to increase the wheelbase and track of a truck. This process involves adding metal plates between the frame rails in order to spread them apart. You can achieve more stability and handling while also gaining extra inches for larger tires by doing this.

Frame stretching is a common modification for off-road trucks and can be done at home with basic tools. However, it’s important to note that this process can compromise the structural integrity of your vehicle if not performed correctly. This article has provided step-by-step instructions on how to stretch a truck frame.

You can safely achieve the desired results without damaging your vehicle if you follow these steps. If you have any questions, be sure to consult a professional before attempting this modification, and write a comment here to get more tips from professionals. Thanks for reading!