How to Clean Aluminum Gasket Surface

When you are working on a car, there are many things that you need to keep in mind. One of the most important things is making sure that all parts are clean and in good condition. In particular, when you are working on the engine, it is essential to make sure that all of the gaskets are clean.

If there is any dirt or grime on the surface of the gasket, it can cause problems with the seal and lead to leakage. This blog post will show you how to clean aluminum gasket surfaces quickly and easily. We will also cover some common mistakes that can damage the surface and leak. So keep reading this blog post till the end!

What is an Aluminum Gasket?

Before we dive into the cleaning process, let’s quickly discuss what an aluminum gasket is. An aluminum gasket is a sealing material that is used to create a tight seal between two metal surfaces. It can be found in various parts of a car’s engine, such as the cylinder head, oil pan, and exhaust manifold.

Aluminum gaskets are preferred over other materials due to their durability and ability to withstand high temperatures. They are also lightweight, making them a popular choice in the automotive industry.

You may come across different types of aluminum gaskets, including crush, ring, and multi-layer steel (MLS) gaskets. Each type has its unique design and application, but the underlying principle remains the same – to provide a tight seal between two metal surfaces.

Why is Cleaning Aluminum Gasket Surface Important?

As mentioned earlier, a clean gasket surface is crucial for creating a proper seal. When dirt or grime accumulates on the gasket surface, it can cause uneven pressure distribution, leading to leaks and engine damage.

Moreover, if the gasket surface is not cleaned properly before installing a new gasket, it can prevent the new gasket from seating correctly, also causing leaks.

Therefore, it is vital to ensure that the aluminum gasket surface is clean before installing a new gasket or reusing an old one. A well-cleaned surface will allow for proper compression and sealing of the gasket, ensuring optimal engine performance.

Needed Materials:

To clean an aluminum gasket surface, you will need the following materials:

Brake Cleaner or Degreaser:

This will help to remove any oil or grease from the surface. Make sure to choose a cleaner that is safe for aluminum.

Scraper or Razor Blade:

This will be used to remove any stubborn dirt or grime on the surface. Be careful not to damage the aluminum surface while using a scraper.

Wire Brush:

A wire brush can help to remove any remaining debris or corrosion on the gasket surface.

Clean Cloth or Paper Towels:

These will be used to wipe down the surface and ensure that it is completely clean. Avoid using rags as they can leave behind lint.

How to Prepare an Engine Surface for Gasket Installation:

1. Prepare Work Required:

Empty the oil, and remove the spark plugs. Turn off all electrical devices such as radios or alarms, to prevent arcing or ignition during cleaning. Remove the battery from any vehicle in which it has been installed for an extended period (if possible). Do not attempt to clean engine gasket surfaces on a live battery!

2. Cleaning Surface:

Remove all loose dirt and debris from the engine surface. Next, use stiff brushes or abrasive pads to remove any stubborn deposits that might scratch your gasket job. As a final step, spray with water and wipe down again using a rag soaked in isopropyl alcohol. This will remove any remaining debris or surface contaminants. It will also help to prevent any potential corrosion. It is important to note that you should avoid using harsh chemicals like acetone or gasoline, as they can damage the gasket surface.

3. Determining the Proper Finish:

The good finish on your gasket is between 15 and 30 microinches. What kind of finish should you shoot for? The answer depends on the application. Most automotive applications use a surface finish of 20 to 25 microinches (500 to 600 grit wet paper). However, specialty industrial, high-performance, or racing engines might require more precise finishes around 15 to 20 microinches (400 to 600 grit wet paper).

4. Fine Grit Paper:

Use fine-grit sandpaper (600 or finer) wrapped around a block of wood, a stone, or a piece of leather. Make sure the abrasive is not worn out in any way, and be sure there are no deep scratches from prior use. Otherwise, it may make the job more difficult. You can use a rocker arm cover or an exhaust manifold’s flat surface to check your 600-grit wet paper for the amount of work you need to do. It is not recommended to use coarser sandpapers, as they can damage the surface.

5. Measuring Roughness with Surface Finish Comparator:

To measure the surface finish, prepare a comparator. A comparator is a device that allows two different surfaces to be compared relative to each other. If the surfaces are out of parallel (i.e., if one of them bulges or has something sticking up from it), this will cause a measurement error. To make a simple surface finish comparator, wrap a strip of smooth, flat Plexiglas around a metal rod. Or you can use a piece of bronze or aluminum tubing with one end flattened and polished to reduce friction.

10 Effective Methods on How to Clean Aluminum Gasket Surface:

1. Mix Some Baking Soda:

If you want to clean the aluminum gasket surface, mix some baking soda in lukewarm water. You must ensure that there is not too much water so it can be kept on the gasket surface for a few minutes. After a few minutes, rinse it with clean water and dry it with cotton fabric. The baking soda will help to remove any stubborn dirt or grime from the surface.

2. Use Some Alcohol:

Spray some alcohol on the gasket surface, wait for a few minutes and then wipe it with dry cotton fabric. You will find that the aluminum gasket surface looks new after this procedure. Alcohol is a good degreaser and can be used to remove any oil or grease from the surface. However, make sure to use isopropyl alcohol instead of rubbing alcohol as the latter may contain oils or additives that can harm the gasket surface. But if you do not have access to isopropyl alcohol, then rubbing alcohol can also be used.

3. Use Some Vinegar:

You can also use vinegar to clean the aluminum gasket surface. Just dip some tissues in vinegar and wipe the gasket surface with it. After some time, rinse it with clean water and dry it with a cloth or tissue paper. You can also mix vinegar with water in a 1:1 ratio and use it as a cleaning solution. It is a safe and natural option for cleaning. The acetic acid in vinegar can help to dissolve any mineral deposits or corrosion on the gasket surface.

4. Clean With Petroleum Jelly:

Use petroleum jelly to clean the aluminum gasket surface. Just apply some jelly to your fingertips and rub it on the gasket’s surface for a couple of minutes. Then, wipe it with clean cotton fabric. You will find that the gasket surface looks new after this process. Petroleum jelly can help to remove any rust or corrosion on the surface, making it easier to clean. It also provides a protective layer to prevent future corrosion.

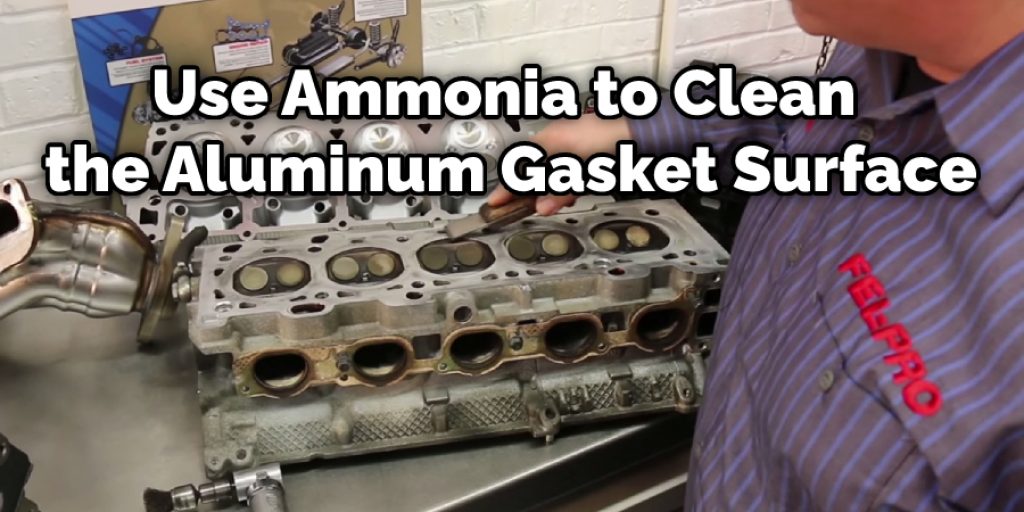

5. Use Some Ammonia:

You can also use ammonia to clean the aluminum gasket surface. For this, you need to mix some ammonia in mild water and then dip a cotton swab in it. Then, rub it on the gasket surface for a couple of minutes. After some time, wash it with water and dry it with a cloth or tissue paper. You can also mix equal parts of ammonia and water in a spray bottle and use it as a cleaning solution. Ammonia is a strong cleaner that can help to remove any tough stains or grime on the surface.

6. Use Soft Bristle Brush:

You can also use any soft bristle brush to clean the aluminum gasket surface. It is better to avoid hard brushes. Use it for a few minutes and rinse it with lukewarm water. Dry the gasket surface with dry cotton fabric. Make sure to use a non-metallic brush as metal brushes can scratch the surface. Otherwise, it may cause more harm than good.

7. Clean With Toothpaste:

You can also clean the aluminum gasket surface by using toothpaste. Just dip some soft bristle brush in toothpaste and scrub it on the gasket surface for a couple of minutes. Then wash it with water and dry the gasket surface with tissue paper or cloth. Toothpaste contains mild abrasives that can help to remove any stains or grime on the surface. You can also use a toothbrush instead of a brush to clean the surface.

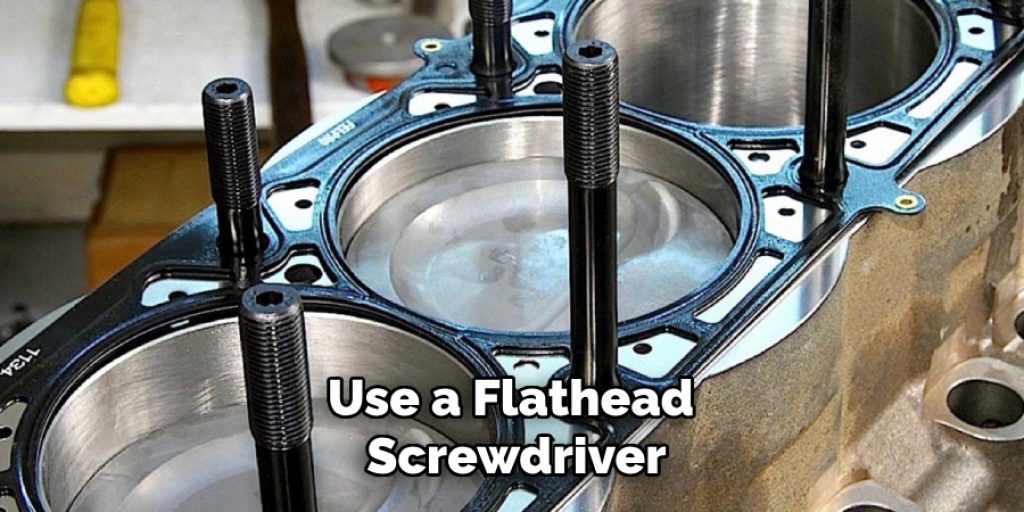

8. Use a Flathead Screwdriver:

Use a flathead screwdriver to clean the aluminum gasket surface. For this, rub it on the gasket surface for a few minutes and then wash it with water. After some time, dry it with a soft cloth or tissue paper. It can help to remove any stubborn dirt or grime from the surface. But make sure to use a flathead screwdriver with a plastic handle as metal handles can scratch the surface.

9. Use Some Dish Soap:

Mix some dish soap in lukewarm water and soak the gasket surface in it for a few minutes. Then, use a soft bristle brush to clean the aluminum gasket surface. After some time, wash it with water and dry the gasket surface with a cloth or tissue paper. But make sure to use a mild dish soap as harsh ones can damage the surface. You can also use a mild detergent instead of dish soap.

10. Clean Surface Using Bleach:

If you want to clean the aluminum gasket surface using bleach, prepare a bleach mixture and water. Immerse the gasket surface in it for some time. Then, take it out and rub it with a soft bristle brush. After some time, wash it with water and dry the gasket surface with tissue paper or cloth.

Following these methods can help you to clean the aluminum gasket surface effectively. However, make sure to test any cleaning solution on a small area first before applying it to the entire surface. This will prevent any potential damage or discoloration of the gasket surface. Regular cleaning and maintenance of aluminum gaskets can help prolong their lifespan and ensure optimal performance.

How to Clean Aluminum Gasket Surface Using Petroleum Distillates?

Fill a small tub with petroleum distillate. Place the engine block in the tub and allow it to soak for several hours. Use gloves when removing the gasket to avoid touching it with your bare hands.

Remove all dirt and grime from the flat section of the gasket using a micro-fiber cloth. Dip an old toothbrush in petroleum distillate, and use it to clean off any stubborn bits of dirt or grime that remain on the gasket surface. Rinse the petroleum distillate off with water and allow it to dry thoroughly.

Frequently Asked Questions:

Q: Is There Any Other Cleaning Method That Would Be Better Than Using a Spray Bottle?

A: Washing a gasket with a spray bottle of water is the easiest way to clean an aluminum gasket surface. You can use this method even if you have carbon deposits stuck on the surface of your oil pan or engine block.

However, because there are still some folks out in the world who think that washing an aluminum gasket surface is not good enough, we’ve added a discussion here in this blog post. So please read on if you want to know how to clean aluminum gasket surface thoroughly.

Q: How Often Should I Clean My Aluminum Gasket Surface?

A: There is no set frequency for cleaning aluminum gasket surfaces. It will depend on how often you use your cooker and the environmental conditions where the cooker is stored. For example, clean more frequently in dusty, dirty areas; in pristine environments, less frequently.

If humidity or water exposure might cause rusting of the aluminum, you should probably wipe it down every time you use the cooker. In addition, if your cooker is stored in an enclosed space, you might want to inspect it once a month for leaf litter or other debris that could block ventilation holes and conduct moisture under the lid.

Q: What Should I Use to Clean the Mating Surface of the Aluminum Engine Block?

A: When installing gaskets, it is best to have the engine surface as clean as possible. There are many ways to clean an aluminum engine block, but most techniques involve a cleaning solution and something to scrub the block with, such as a toothbrush. A wire brush may be required if the engine block is severely corroded or rusted. You can also use a gasket scraper, but be careful not to scratch the mating surface.

Q: How Do I Clean Aluminum Engine Blocks?

A: Most professionals will use a solvent such as Gunk or Carburetor and Brake Parts Cleaner to clean aluminum engine blocks, although some may prefer brake cleaner. The product is sprayed on the block surface, allowed to soak for a few minutes, and then quickly rinsed off with water. The surface of the block can also be scrubbed with a toothbrush or similar brush, and all solvents should be rinsed off with water.

Q: Can I Use Steel Wool to Clean Aluminum Gasket Surfaces?

A: Steel wool is not recommended for use on aluminum gasket surfaces as it can scratch and damage the surface. It is better to use a soft bristle brush or cloth when cleaning aluminum gaskets. It is also important to use a cleaning solution that is safe for use on aluminum surfaces. If you are unsure about the compatibility of a product, it is best to test it on a small area first before using it on the entire surface. Alternatively, you can consult with the manufacturer or an expert for guidance on suitable cleaning methods and products for your specific gasket type.

Conclusion:

After reading the above article, you must understand how to clean aluminum gasket surfaces. It is better to use any method to clean the gasket surface and apply it on the gasket surface for a few minutes.

After some time, wash it with water and dry it with a soft cloth or tissue paper. So, use any of the above-given cleaning methods and clean your aluminum gasket surface. You will find that it looks as good as new after this procedure. We hope this blog post has been helpful. If you have any questions or want to know more, then feel free to comment below!

You Can Check It Out To Remove Deck Stain From Aluminum Siding