How to Assemble and Install Pneumatics

Pneumatic cylinders are quite similar to hydraulic cylinders. But unlike them, it uses gas or pressurized air with the help of an air compressor. The pressurized gas inside the pneumatic chamber travels through the hoses. With the advantages of low friction and compressible air pressure, Pneumatic supplies unmatched power. A ton of air will travel easily and although compressibility. Moreover, its response and cycle times are unparalleled. That’s why it has significant importance at the industry level. Okay, that’s enough talking about the essentialities of Pneumatic cylinders. But do you know how to assemble and install pneumatics?

The correct installation of pneumatic cylinders is crucial. It also bears significant importance in your overall room design. If you somehow fail to install the cylinder correctly, you may end up with a system that may not work properly. But as you know, you are here, you won’t have to worry about that. I will show you the exact way of assembling and installing the pneumatics. So, without any delay, let’s dive in!

How to Assemble and Install Pneumatics

The installation process of the pneumatics is usually done in two ways. These are:

The cylinder may be placed on the system bench and rigidly bound to its frame while the device is static.

When the cylinders are part of a more complex connection, they must be able to move on their mounting surface to function properly.

So, you have first to identify what type of setting you have on your machine and start the mounting process. The piston rod end may be placed in one or more planes in certain machine applications. However, the piston rod end stays free in certain other frameworks, such as basic push systems. The construction of the whole unit can adopt different styles of pneumatic cylinders, namely the rodless type. Still, in this situation, you must follow the supplier’s directions on how to mount the cylinder.

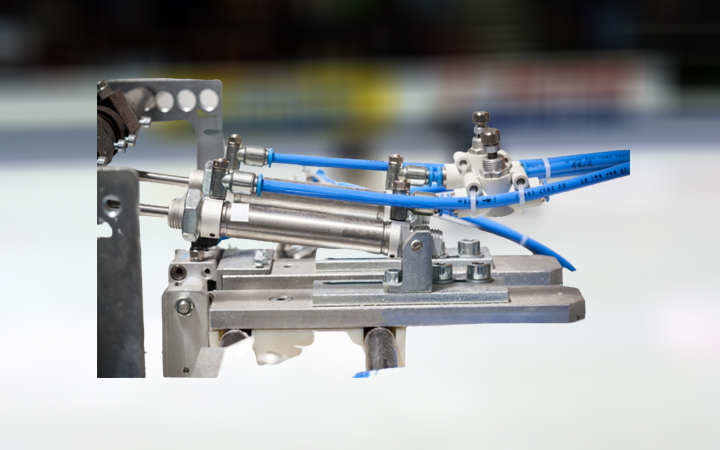

However, there are several ways of installing pneumatic cylinders. At first, you have to reduce the side loads on the piston. Once you have completed that, you have to look for the mounting fixtures of your machine. If your cylinder has a thread covering the front and rear end, you can easily clamp it by using a locknut. In this case, you can also fit them with the tie rod extension.

On the other hand, if your machine supports the installation through parts, you must maintain swivel capability at the mounting point. In this case, you have to make the attachment at the end of the piston rod so that you can use it with a universal eve, a hinge, or clevis. Keep these things in mind and follow the instruction of the suppliers; thus, you will be able to assemble and mount the Pneumatic properly.

Frequently Asked Questions

What Do You Need to Build a Pneumatic System?

To build a pneumatic system, you will need the following:

1. A compressor – This is the heart of your pneumatic system and needs to be powerful enough to compress the air.

2. A hose connects the compressor to the various objects or areas you want to pressurize.

3. Pneumatics tools are used to control the pressure and flow of air in your system.https://diyquickly.com/how-to-install-a-split-system-air-conditioner-on-an-internal-wall/

4. Gauges and sensors – These are used to monitor the pressure and flow of air in your system.\

What Are the Parts of a Pneumatic System?

A pneumatic system comprises several different parts that work together to deliver air or other gases to the desired location. These parts include:

• The air or gas source – This part can be anything from an air compressor to a gas tank.

• The delivery line – This part includes any pipes, hoses, or other devices used to transport the air or gas to the appropriate location.

• The controller – This part is responsible for regulating air or gas flow and ensuring that it reaches the destination safely and promptly.

What Is Pneumatic Circuit Diagram?

A pneumatic circuit diagram is a schematic diagram that shows the flow of air and fluid in an industrial or commercial setting. It illustrates the operation of machines, valves, pumps, and other components.

Which Tools Operate on Pneumatic Power?

Pneumatic tools include drills, saws, hammers, and other hand-held power tools. They are powered by compressed air, delivered through a hose or an air tank.