How to Build a Pump House

Are you looking to construct a pump house in your homestead or garden? If so, the task is more achievable than you think! With the right knowledge and resources, building a waterproof and durable pump house that meets all of your needs can be a breeze. In this article, we will take you through what is involved in constructing a robust pump house from start to finish.

From finding ideal locations to selecting appropriate materials for optimal longevity – we’ll give you an insight into everything you need to know about how to build a pump house. So let’s get started already!

Does a Pump House Need Ventilation?

Yes, a pump house needs ventilation to avoid the build-up of CO2 and other toxic gases. An adequate number of vents should be installed at the top of the structure to ensure good air circulation. Additionally, a fan can be used to help keep the air inside circulating.

It is important that these vents are protected from animals and debris; otherwise, they won’t function properly. If there is an electric motor running in the pump house, then it also needs its own separate vent, as this will prevent overheating. Proper ventilation helps protect both people and equipment inside the pump house.

It is also important to consider the environmental conditions in and around the pump house. Considerations should include wind direction, temperature and humidity levels, noise pollution, and any other potential weather events. Ensure adequate protection against bad weather such as storms or high winds.

Keep in mind that these environmental factors can cause damage to equipment inside the structure if not taken into account. Lastly, ensure proper drainage is installed around the area to prevent flooding or water accumulation near the pump house which could damage it over time. Additionally, this will prevent the pump house from becoming waterlogged and create a breeding ground for pests.

By taking all of these considerations into account, you can ensure that your pump house is properly ventilated and protected from the elements. This will help keep it functioning efficiently for many years to come.

10 Methods on How to Build a Pump House

A pump house is a structure that is built to house water pumps and related equipment. Here are 10 methods for building a pump house:

1. Choose a Location

Select a location for your pump house that is near the water source and away from any potential hazards, such as flood-prone areas. The area should be fairly level and accessible for digging and construction.

Make sure the location is also away from your property line to avoid any potential neighbor disputes. If possible, select an area that has access to electricity. Although you don’t need a power source for the pump itself, it can be helpful to have electricity nearby if you ever want to add lights or other features to the pump house.

2. Obtain Necessary Permits

Check with your local government to see if you need a permit to build your pump house and obtain any necessary permits before beginning construction. Additionally, if you are using a contractor to do the construction work, they may need up-to-date licenses and permits in order to legally perform the work.

While permits may be a hassle to obtain, they ensure you are following all the necessary regulations and that your pump house is built in compliance with building codes. Though the process for obtaining permits may vary from state to state, most require some type of fee and can take several weeks to be approved.

3. Choose Materials

Select materials that will be durable and weather-resistant. Common options include wood, metal, and concrete. Some materials may require regular maintenance, so consider the amount of time and effort you can commit to upkeep.

Consider a combination of materials for your pump house as well. For example, use masonry blocks and a metal roof to weatherproof the structure. Make sure all materials are suitable for the local climate. However, for long-term durability, steel is often the best option. Make sure to use corrosion-resistant screws and bolts, as well as weatherproofing agents.

4. Design and Plan

Develop a design and plan for your pump house, including the size and layout of the structure and the equipment it will house. Choose a location that will allow for easy access to the pump house and provide enough space around it.

Consider factors like sunlight, ventilation, and drainage when selecting a location. Make sure the site is free of power lines, tree roots, and other objects that could interfere with the construction of your pump house. Though it may be tempting to just begin building, having a detailed plan will help you avoid costly mistakes or unexpected challenges.

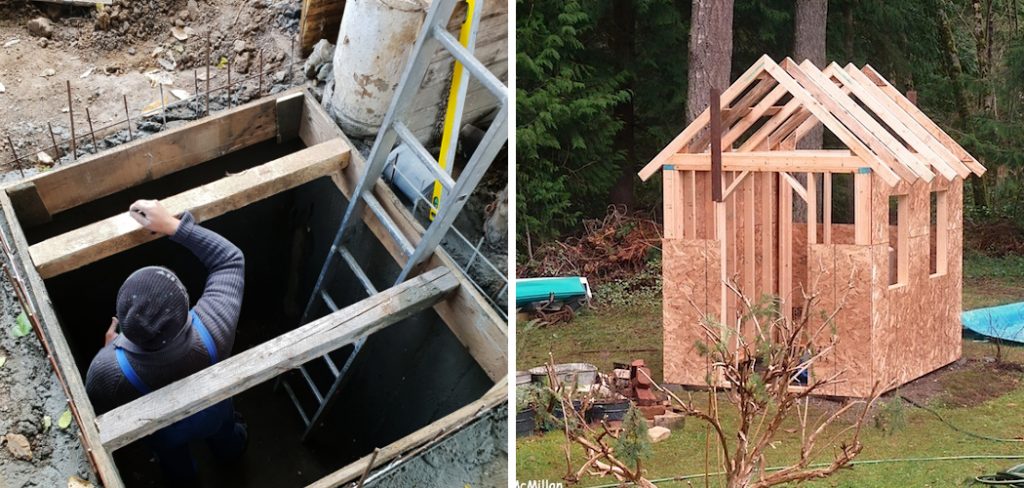

5. Build Foundation

Build a strong foundation for the pump house using concrete or other suitable materials. Make sure the foundation is level and extends at least 12 inches below grade. For a concrete footing, use at least 4″ of concrete, reinforcing as needed with rebar.

Be sure to check your local building codes for exact requirements. To ensure your foundation is stable, backfill with gravel and compact the site to reduce settling. Make suer check gradually slope the concrete footing away from the building to reduce water pooling around the pump house.

6. Build Walls and Roof

Construct the walls and roof of the pump house, making sure they are properly insulated and ventilated. Consider using concrete blocks, cinder blocks, or poured concrete walls for the four side walls.

Adding a layer of insulation to the walls will help keep the pump house cooler in summer and warmer in winter. For the roof, use strong metal panels that are designed to withstand extreme weather conditions. Connect these panels to the walls using roofing screws and washers.

7. Install Doors and Windows

Install doors and windows in the pump house to provide access and natural light. Use a pre-hung door with hinges to ensure it fits properly. If you don’t have the necessary tools for installation, hire a contractor for the job. You can also install windows that are designed for pump houses or sheds and mount them securely in the openings.

Make sure to use caulk or weatherstripping around the edges of any windows or doors to create a weather-resistant seal. Once everything is installed, use exterior paint to finish the job and make the pump house look attractive.

8. Install Electrical and Plumbing

Install electrical and plumbing systems as needed to power and connect the water pumps and related equipment. Be sure to follow all local building codes and regulations when installing the electrical and plumbing systems.

Check with your municipal water department or other regulating authorities to ensure that you are following proper procedures. Additionally, hire a professional electrician and plumber to assist in connecting the pumps, valves, and other equipment properly.

9. Test Equipment

Test the water pumps and related equipment to ensure they are functioning properly and safely. Make sure the pumps are set to the right pressure and that all wiring is secure. If any problems arise, make necessary repairs promptly.

Check for leaks, listen for strange noises, and look for loose connections. To ensure optimal performance, regularly inspect the pumps and related parts and replace worn components as needed.

10. Maintain and Upkeep

Regularly maintain and upkeep the pump house, such as by checking for any damages or issues, cleaning the interior and exterior, and replacing any faulty equipment or parts. Establish a regular maintenance schedule and follow it to ensure the pump house remains in good condition.

Additionally, regularly check for any potential problems that may be caused by issues such as flooding or pests. If any serious damage is found, consult with an expert before attempting repairs yourself.

Things to Consider When Building a Pump House

1. Location

Finding the right location for your pump house is essential to ensure its structural integrity and efficiency. Make sure the area you choose is level and well-drained, preferably with a solid foundation to provide extra stability.

2. Size

The size of your pump house should accommodate both your current needs and any potential future upgrades. If you plan on adding additional pumps or other equipment, make sure the structure is large enough to fit it all.

3. Materials

The materials used to construct your pump house are also important factors to consider. Make sure the materials you choose are strong and durable, capable of withstanding any extreme weather conditions or temperature swings.

Conclusion

A pump house can be an essential part of a home, as it allows for easy access to the water source and also adds an extra element of security. With proper research, planning, and construction methods, you can successfully construct your own pump house with confidence.

Understanding the basics of building a pump house is critical; by following the steps provided in this blog post, you should have the fundamentals to move forward with the project. Thanks for reading, and we hope this has given you some inspiration on how to build a pump house!