How to Dress a Grinding Wheel

Dressing a grinding wheel is an important step for anyone who works with grinders. The process serves several purposes: it removes the old and worn abrasive particles, trues the wheel to ensure it runs evenly, and creates a cutting face that can be used to shape or finish parts.

When done correctly, dressing a grinding wheel will ensure the wheel will be able to perform its job effectively. It is also important for safety reasons, as an improperly dressed wheel can cause dangerous sparks or uneven grinding.

There are many benefits to understanding to dress a grinding wheel. Properly dressing a grinding wheel will ensure that the wheel performs at its peak and can improve overall safety. A well-dressed grinding wheel will have improved performance due to better cutting and truing of the surface of the wheel.

This not only improves the quality of the finished product but can also help extend the grinding wheel’s life. You can find step-by-step instructions on how to dress a grinding wheel in this blog article.

Step-by-step Instructions for How to Dress a Grinding Wheel

Step 1: Inspect the Grinding Wheel

Before you begin dressing the grinding wheel, it is important to inspect it. Look for any cracks, chips, or other damage on the surface of the wheel and check that the abrasive grains are still firmly bonded together with a strong bond. If you find any damage, then it may be best not to use the wheel until it can be properly repaired.

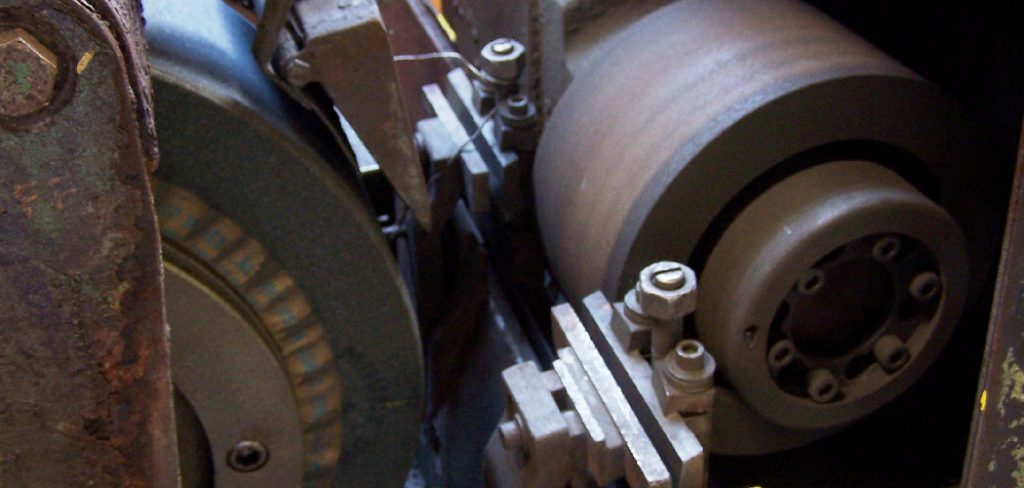

Step 2: Mount the Grinding Wheel

Before you can begin dressing the grinding wheel, you will need to mount it onto your machine securely. Ensure the wheel is firmly attached and all safety precautions are taken while mounting it. Depending on what type of grinding wheel you are using, a specific tool will be required to dress it. Make sure you select the right dressing tool for your wheel to clean and shape it effectively.

Step 3: Securely Attach the Dressing Tool

Once you have selected the appropriate dressing tool, you will need to attach it securely to the grinding wheel. Ensure that it is properly secured so that it does not slip off during the dressing process. Before you begin dressing the grinding wheel, make sure to adjust the settings on your machine according to the manufacturer’s instructions. This will ensure that you dress the wheel correctly and without damaging it in the process.

Step 4: Start Dressing the Grinding Wheel

Once all of the settings are adjusted, you can begin dressing the grinding wheel. Move the dressing tool slowly and steadily across the surface of the wheel. Ensure to keep a consistent pressure throughout to get an even finish on all sides of the wheel.

After you have finished dressing the grinding wheel, take a moment to inspect your work. Look for any irregularities or unevenness on the surface and ensure that all areas have been evenly dressed. If there are any issues, then you may need to adjust the settings again before continuing with the job.

Step 5: Cleanup and Dispose of Waste

Once you have inspected the wheel, make sure to clean up any waste or debris in the area. This is especially important if you use a grinding wheel with an abrasive material like diamond grit since it can be hazardous if improper disposal. When you are finished with dressing the grinding wheel, make sure to store it in a safe and secure place. This will ensure that it is still in good condition when you need to use it again.

Step 6: Maintain a Regular Maintenance Schedule

Finally, it is important to maintain a regular schedule for dressing and to maintain your grinding wheel. This will help ensure that it performs at its best and lasts for years. It is also important to ensure that all safety precautions are followed every time you use the wheel to avoid any potential accidents or injuries.

Follow these steps to properly dress a grinding wheel and keep it in optimal condition. Doing so will help ensure your grinding wheel performs well and lasts longer.

Safety Tips for How to Dress a Grinding Wheel

- Always wear safety glasses and protective clothing when dressing a grinding wheel. This will help protect the user from flying debris and sparks created by the dressing process.

- Ensure to properly secure the wheel on a grinding machine before dressing it. The wheel can cause serious injury or damage if it is not firmly fastened.

- Shut off the grinding machine and unplug it before beginning to dress the wheel. This will help avoid potential electric shock or fires caused by sparks in contact with electrical components.

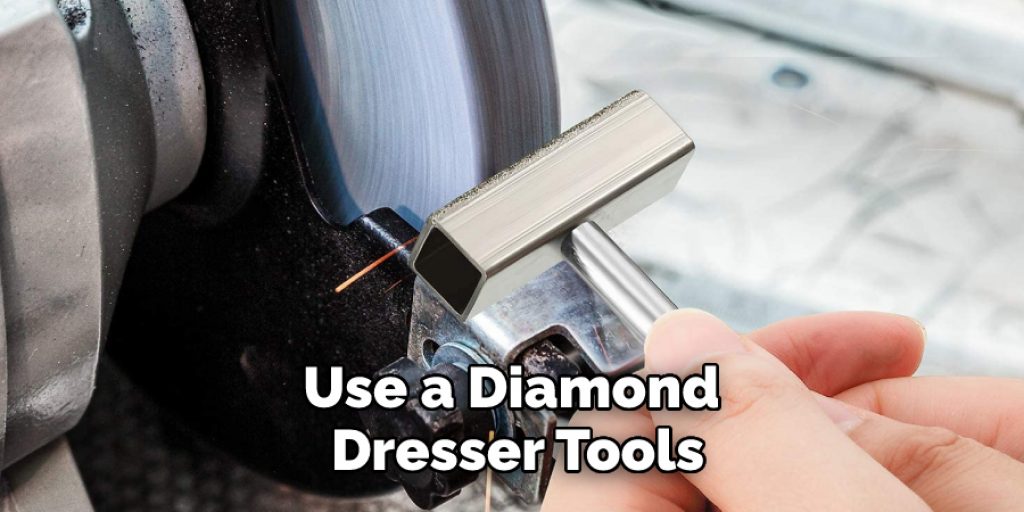

- Use a diamond dresser or other similar tool to dress the wheel surface evenly. If done improperly, this can cause an uneven surface and potentially reduce the performance of the grinding wheel.

- Clean any debris or clogged material from the wheel dressing area before starting to dress it. This will help ensure that the wheel is dressed correctly and safely.

- Inspect the wheel for any damage, like cracks or chips, before dressing it. If there are any signs of damage, the wheel should not be used and must be discarded in a safe manner.

- Always keep your hands away from the grinding surface while dressing it to avoid potential injury or burns. If any parts of your skin come into contact with the wheel while it is being dressed, wash the area immediately and seek medical attention if necessary.

Following these seven safety tips when dressing a grinding wheel can help ensure that the process is done properly and safely.

How Often Should a Grinding Wheel Be Replaced?

Grinding wheels should be replaced regularly to maintain a sharp, consistent grinding surface. Depending on the workload, frequency of use, and type of material being ground, it is recommended that a grinding wheel be replaced at least once a year or after 2,000 hours of use.

Before replacing a grinding wheel, inspecting for any signs of wear or damage, including cracks, chips, and signs of excessive heat, is important. If any such signs are found, the grinding wheel should be immediately replaced so as to maintain an even surface for efficient operation.

When replacing a grinding wheel, it is also important to dress the new wheel with a tool designed for this purpose. Dressing helps ensure that the grinding wheel is properly shaped and provides a sharp cutting surface.

Dressing a grinding wheel will vary depending on the wheel type, so it is important to refer to the manufacturer’s instructions for proper dressing techniques. By following these guidelines, you can ensure that your grinding wheel is in optimal condition and provides consistent results throughout its lifespan.

How Should You Clean and Store a Grinding Wheel?

It is important to clean and store a grinding wheel properly in order to ensure that it lasts for many years. To clean the grinding wheel, you should use a stiff brush or cloth to remove any dust and debris from the surface. If using a brush, make sure to use one with soft bristles so as not to damage the teeth of the grinding wheel.

Once the surface of the grinding wheel has been cleaned, it should be covered with a light coat of oil to protect it from rust and corrosion. Additionally, the grinding wheel should be stored in a cool, dry place away from direct sunlight or any other sources of heat. When not in use, you should also ensure that there is no pressure on the grinding wheel, which can cause it to become deformed or damaged. By following these simple steps, you can ensure that your grinding wheel remains in optimal condition and will be ready for use whenever you need it.

Conclusion

One of the main disadvantages of dressing a grinding wheel is that it can be time-consuming and require skill to do properly. Without proper care and attention, the dressed wheel may not perform as expected or may even become damaged during use. Additionally, dressing can cause a significant amount of material to be removed from the grinding wheel, shortening its lifespan.

In conclusion, dressing a grinding wheel is an important part of the grinding process that ensures your safety and accuracy. It involves selecting the right diamond or abrasive dresser for your particular job, setting the correct speed and depth of cut, and regularly checking to ensure your wheel is running efficiently.

Understanding how to dress a grinding wheel properly will save you time in the long run and help you produce better results. Safety should always be a top priority when using a grinding wheel, so make sure you follow all the proper guidelines. I hope this article has been beneficial for learning how to dress a grinding wheel. Make Sure the precautionary measures are followed chronologically.