How To Fix A Bad Concrete Job

Concrete is a popular building material that has been used for centuries. It is a versatile material, which means it can be used in many different ways to create structures of all sorts. Concrete jobs are often done by contractors and builders who specialize in this type of work. Concrete is a strong and durable material that can be used for both indoor and outdoor applications. It is an excellent choice for driveways, patios, sidewalks, pool decks, and other outdoor areas.

However, there might come a time when you need to do some concrete repair on your own home or at the office. This article will show you how to fix a bad concrete job with just the basics from your local hardware store! This particular repair was done in only about 20 minutes using some concrete mix, a wire brush, and a bucket of water.

Materials Needed

- Bucket

- Water

- Cement mix

- Leveler or additive (optional)

- Hammer and chisel

- Drill with an augur bit attachment (optional)

- Level or a laser level

- Safety goggles

- Ear protection

Instructions: How to Fix a Bad Concrete Job

Step One:

Make sure the median is wet or slushy before pouring in your cement mix and leveler. Otherwise, it will be difficult to properly smooth out the concrete as you are working on the project. If there are any areas of higher ground, use this to your advantage and place some of the concrete in those areas.

Step Two:

Before you start to smooth out the cement, you need to check for any high points that you need to take care of. To do this, use a level or laser leveling device. Once you have found the high points, apply a small amount of cement to them using a trowel. Then, use the trowel to spread the cement over these areas until the area is even. Let the cement set for about 20 minutes before you continue.

Step Three:

After wetting the concrete, use a trowel, steel shovel, or squeegee to smooth it out by dragging it over one section at a time while applying downward pressure. This will help to remove any ridges from previous passes and to eliminate any air pockets between slabs, which can create large voids when dried if not dealt with early on.

Dry the concrete completely before allowing foot traffic on it. The concrete needs at least a week of dry time before being used, but better to give it 2-3 weeks to cure fully. Do not allow the concrete to freeze for at least 2 weeks after installation, this can cause your concrete to crack.

Step Four:

Let dry overnight, then come back and put down an additional layer of sealant (cement) mixed with sand in a ratio of one part sealant to two parts sand. (Remember: start with four parts sand, then add a little more to help smooth it out.) Repeat this process of drying and sealing until you’re happy with the surface.

Step Five:

Drag a squeegee perpendicular to the first layer of sealant. This will help ensure that all air pockets are removed and that there is no excess moisture present in the concrete. Walk back over the dampened concrete after the sealant has had time to settle in. This will help you to determine if any additional coatings are needed to get the optimal look.

Step Six:

Go spray down your concrete surface with water, using as much volume of water as possible to remove any remaining dirt or dust particles from the surface before walking on it. This will also help the sealant to bond better with the concrete. Apply a generous amount of the concrete sealant on your concrete surface and spread it evenly with a broom or a brush. Do not forget to cover the edges and corners of the concrete as well.

Step Seven:

Continue spraying water over your surface for a maximum of two hours after finishing your work, and make sure that you keep wetting down any area where there might be dust or dirt particles accumulating. This will ensure that those areas stay sealed properly. It is important to note that while using the spray on a clear or slightly warm surface will increase adhesion, applying it to a cold surface can cause undesirable adhesion.

Things to Consider for Fixing a Bad Concrete

Buckling: Sometimes, when new homes are being built, the contractor might skimp on reinforcing the outside of walls with rebar. This will cause the concrete to buckle as it dries.

Cracking: Cracks can happen if there are no rebar reinforcements for new homes or pour too fast on a hot day and cold mix hits your freshly poured concrete- this causes it to shrink and crack!

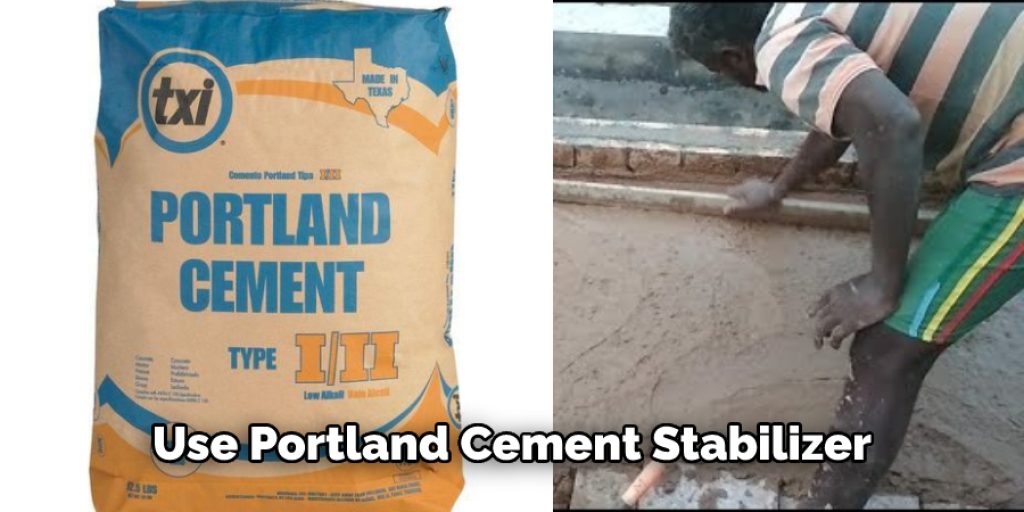

Mitigating Agents: The best way to fix any of these problems is by using special additives like portland cement stabilizers that have been designed especially for fixing bad concrete jobs.

You should also use bentonite clay which helps with water absorption in all types of material, including brick, mortar, cinder block, etc. So be sure not to forget that when patching up old cracks in foundations etc.

Tips & Warnings

1) Be sure to measure twice and cut once when cutting boards for use as levelers, so they are even across all portions! A good rule of thumb is placing them at least every eight feet and in a pattern that alternates from left to right.

2) Remember to use the appropriate PPE- safety glasses, gloves, etc.- when working with concrete or other hazardous substances!

3) Mixing concrete in a wheelbarrow is the easiest way to transport it, but you can also use a bucket or pail.

4) Be sure not to pour water on fresh cement. This will cause it to dry too fast and become brittle- that’s how some of your “concrete” may have come out cracked after all!

5) Use temp strips/laser thermometer if you’re unsure about what temperature the product should be before pouring. The liquid mix needs to have reached at least 60 degrees Fahrenheit for best results (though this varies depending on where you live).

Common Signs of Bad Concrete Installation

- Poor Surface Quality: Poorly installed concrete can often result in a rougher, less attractive finish that may include visible markings, uneven surfaces, and other imperfections.

- Low Strength: Bad concrete installation can result in weaker-than-expected concrete and is prone to cracking or disintegration over time.

- Improper Curing: Proper curing of concrete during installation is crucial for reaching its full strength and durability potential. If not done properly, the quality of the concrete will suffer, and its lifespan may be shortened significantly.

- Uneven Slab Height: When the slab height isn’t at the correct level, it can create a range of risks, from wheelchair access problems to safety hazards when walking across it.

- Visible Seams: Visible seams along the open joints of a concrete slab usually indicate poor installation, as these should be covered up before you pour more cement on top of them.

Frequently Asked Questions

Can You Fix a Bad Stamped Concrete Job?

Yes, you can fix a stamped concrete job if it is not too bad. You will need to do a few things to fix the stamped concrete job.

The first thing you will need to do is clean up any mess made. This could include removing chunks of concrete, debris, and mud. It would help if you also tried to clean any areas where the sealant has cracked or peeled off.

Next, you will need to apply a new sealant. This will help protect the concrete and make it look new again. You can use a sealant specifically designed for stamped concrete or a sealant that is safe for both stamped concrete and mortar joints.

After applying the sealant, you will need to wait until it dries before finishing the job. This may take several hours or overnight, depending on the weather conditions. Once the sealant has dried, you can finish the job by sanding and painting the area where the stamping was done.

What Does a Bad Concrete Job Look Like?

A bad concrete job can look like wet, cracked, and stained concrete. It can also have large chunks that are missing or broken off, making it difficult to walk on.

Can Concrete Be Resurfaced?

Yes, concrete can be resurfaced. The most common type of resurfacing is called acid-base neutralization, which restores the original color and texture of the concrete while also protecting it from future damage.

There are a few things you need to keep in mind when resurfacing your concrete:

• Make sure the surface is clean and free of any oils or dirt.

• Use a high-quality resurfacing product that is safe for use on concrete.

• Follow the instructions carefully to avoid any damage to the concrete.

What Is the Best Concrete Repair Product?

There are many concrete repair products on the market, but the best one depends on the type of concrete and the severity of the damage.

If you have concrete that has been damaged by water, then a product like Concrete Repair Plus may be a good option because it is formulated to resist water and weathering.

Conclusion

Fixing a bad concrete job is not always easy. You could be left with the ugly, unsightly results of improperly mixed cement and other materials that have caused your project to fail miserably.

However, there are several steps you can take to fix the problem before it becomes worse. In this blog post, we have gone over how to fix a bad concrete job and mistakes you should avoid when trying to do so. If you would rather have time to take care of this problem, follow our step-by-step guide on this topic.