How to Measure Torque on a Bolt

Bolts play an important role in many assemblies, and it is critical to ensure that they are properly torqued. In this blog post, we will explain how to measure torque on a bolt and provide tips for achieving the correct level of tightness. Keep reading to learn more!

A torque wrench is a perfect tool for tightening bolts to the correct specifications, but it can be tricky to determine how much torque is necessary in some cases. In this blog post, we’ll show you how to measure torque on a bolt and provide some tips for getting the right reading. Let’s get started!

Why Do You Need to Measure Torque on a Bolt?

1. To Prevent the Damage Bolt

Over-tightening a bolt can lead to its failure or damage, while under-tightening can result in loose connections. So it is very important to measure the torque on a bolt to prevent any damage. Otherwise, it could result in dangerous situations.

2. To Ensure Proper Function

Measuring the torque on a bolt ensures that it is tightened properly for optimal function and safety. This is especially important in industries like construction or automotive, where loose bolts can lead to hazardous situations. So be careful and always measure the torque on bolts.

3. To Meet Specifications

In many industries, there are certain specifications or guidelines for how tight a bolt should be. By measuring the torque, you can ensure that the bolt is tightened to meet these specifications. This also helps to maintain quality control in manufacturing processes.

4. Quality Control

Measuring the torque on a bolt is also a way to maintain quality control. By making sure that each bolt is tightened properly, you can ensure the overall quality and integrity of the product or structure. So it is very important to measure the torque on a bolt.

5. For Assessment

Measuring the torque on a bolt can also be used for assessment purposes. By consistently measuring the torque, you can keep track of how well the bolt is holding up and if any adjustments or replacements are necessary. This helps to maintain the overall stability and safety of the structure or product.

Tools You Will Need to Measure Torque on a Bolt

- Torque wrench

- Calibration device

- Bolt

How to Measure Torque on a Bolt in 7 Steps

Step 1: Choose the Appropriate Torque Wrench

Select a torque wrench that can apply the appropriate amount of force for your bolt and has the correct units of measure. Be careful while selecting the torque wrench as using an incorrect one can lead to erroneous measurements or damage to the bolt.

Step 2: Position the Torque Wrench on the Bolt

Position the torque wrench so that it is parallel to the axis of the bolt and ensure that it is securely in place. But make sure not to apply any force while doing so, as this can affect the measurement. Otherwise, you may need to re-calibrate the wrench before use.

Step 3: Apply Force Gradually

Slowly apply force on the torque wrench until it reaches the desired level of tension. Make sure not to exceed the recommended torque for the bolt, as this can lead to potential damage or breakage. Be careful to not apply too little force as well, as this can lead to the bolt not being tight enough.

Step 4: Take a Reading

Once the desired level of tension has been achieved, take note of the torque measurement displayed on the torque wrench. It is very important to record the measurement at this point in time, as continuing to apply force can potentially alter the reading.

Step 5: Double Check Measurement

If possible, double-check the measurement by using a different torque wrench or by using a different technique, such as turning the bolt a certain number of rotations. To ensure accuracy, it is recommended to take multiple measurements and calculate the average.

Step 6: Record and Repeat

Record the torque measurement and repeat steps 2-5 for any other bolts that need to be measured. It is very important to make sure all the bolts have an equal amount of tension to ensure the integrity and safety of the structure.

Step 7: Properly Store and Maintain the Torque Wrench

After using the torque wrench, properly store it in a safe and secure location. Also, make sure to regularly maintain and calibrate the wrench to ensure accurate measurements. Be careful and always remember to measure the torque on bolts for safety, quality control, and to meet specifications.

Following these steps will help ensure an accurate measurement of the torque on a bolt. Remember to always be careful and measure the torque on bolts to meet specifications, maintain quality control, and for assessment purposes.

Some Additional Tips to Measure Torque on a Bolt

1. Make Sure the Bolt is Properly Tightened

Before attempting to measure the torque on a bolt, make sure that it is properly tightened to avoid inaccurate measurements. Otherwise, the reading may be lower than the actual torque applied.So make sure to use appropriate tools and follow proper tightening procedures.

2. Use a Torque Wrench

Using a torque wrench is the most accurate and efficient way to measure the torque on a bolt. It allows for precise adjustments and will give an exact reading of the applied torque. Make sure to select the appropriate size and type of torque wrench for the job.

3. Consider Bolt Material and Size

Bolt material and size can also affect the accuracy of torque measurement. So it is important to consider and take into account these factors when conducting the measurement. This is very important in industrial settings where precise torque measurements are crucial for the success

4. Record Results for Accuracy

To ensure accurate results, it is important to record the measurements for each bolt. This allows for easy comparison and helps in identifying any potential issues with a particular bolt.This is very important in maintaining the integrity and safety of a structure or machine.

5. Read and Follow the Manufacturer’s Instructions

Always make sure to read and follow the manufacturer’s instructions for using any tools or equipment, including a torque wrench. This will ensure proper and safe use, as well as accurate measurements.

6. Maintain and Calibrate the Torque Wrench

Regularly maintaining and calibrating the torque wrench is crucial in ensuring accurate measurements. So make sure to follow manufacturer guidelines and protocols for proper maintenance and calibration procedures. This will also help prolong the lifespan of the tool.

Overall, measuring the torque on a bolt is important in ensuring proper tightening and preventing potential issues such as loosening or breakage. By following these tips and using the appropriate tools, you can effectively measure the torque on a bolt.

Frequently Asked Questions

How Do I Know What Type of Torque Wrench to Use?

First, determine the size and thread pitch of your bolt. Then, choose a torque wrench that can handle the appropriate unit of measurement and has a range that includes the recommended torque for your bolt. Make sure to also consider the type of torque wrench, as there are various types, such as click, dial/dial indicator, and electronic.

What if My Torque Wrench Does Not Have the Recommended Torque Level?

If your torque wrench does not have the recommended torque level for your bolt, it is best to use a different one that does. This will ensure accurate measurements and prevent potential issues with the bolt. It is also important to always follow manufacturer recommendations and specifications for proper tightening of a bolt.

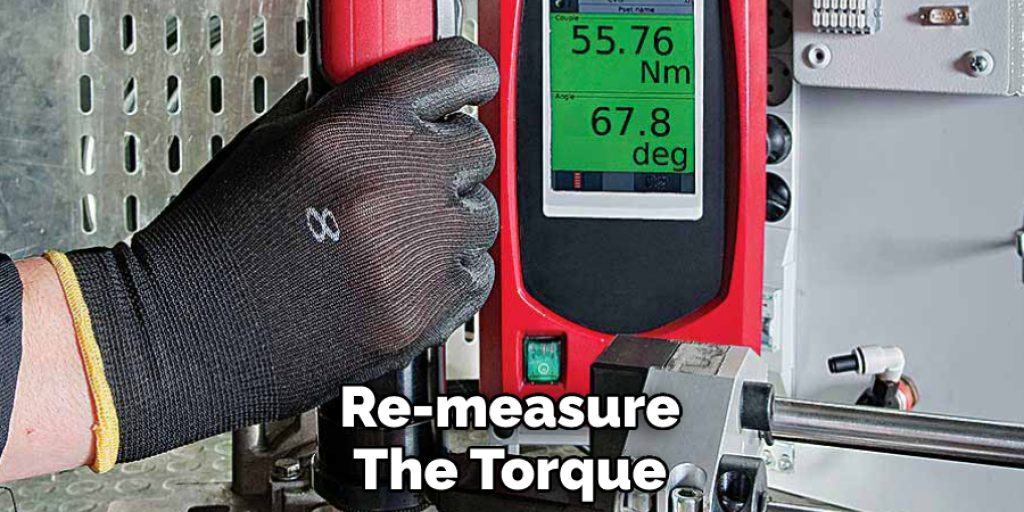

When Should I Re-Measure Torque on a Bolt?

It is recommended to re-measure the torque on a bolt after periods of use or if there are any concerns about the tightness of the bolt. This can help prevent potential issues such as loosening or breakage. It is also important to regularly check and maintain all bolts in a structure or machine to ensure safety and integrity.

Conclusion

Torque is an important factor to consider when choosing bolts for your project. With a little bit of know-how, measuring torque on a bolt is easy and only requires a few tools that can be found around the office. By following the steps about how to measure torque on a bolt in this article, you can be confident in your choice of bolts for your next project.

With this guide, measuring torque on a bolt should be a simple and easy process that anyone can do. By following the steps outlined above, you can ensure that you get an accurate measurement every time. If you have any questions or need assistance, our team of experts at the office is always happy to help.