How to Master the Radial Arm Saw

Several furniture making devices are as functional as a radial arm saw if you weigh the number of activities, this could conduct. After you’ve added one from your carpentry instrument collection, you can consider your grab-tool for most activities. In workplaces with minimal rooms, this could step in for other rooms-gobbling instruments. This can take the load off of your regular workbench and supply it.

The radial arm saw is a unique hand tool because the whole mechanism and blade assembly are installed on an elevated arm. This allows the tool to pass through the material being cut, instead of the material being moved through a stationary blade (like a table saw).

His “woodworking Swiss Army knife” was noticed by my friend across the street, naming his radial arm. He likes the fact that it could be easily changed like a table saw, miter box, or rotating saw.

There are different types of saws that are good for different things. Some people think that a radial arm saw is a good all-purpose saw, while others think that it is not as good as a saw that is specifically designed for one thing.

Both adjacents have marks. A radial arm saw will tear the panels to size, trim the miter and lengthwise split the pieces. Yet its essential nature, a strong motor, and blade hanging from a large version render it an instrument that may lose accuracy. With the joys of a table saw and the mobility of a miter saw, it is in a category of its own. It handles wide boards by cutting through them with a radius blade. It cuts notches, dadoes, tenons, tapers, and moldings.

It relies on the tasks you perform and how much “workaholic” there would be in you, not if a radial arm saw is also for you. Ok, a good one. Whenever it arrives at designing a board or doing daily fixes, the simple radial arm saw is perfect. The radial arm saw has superior precision and is ideal for projects that require high quality cuts or advanced measuring tools.

However, one-purpose equipment such as a miter saw or table saw would best fit you for line furnishings-making or chopping interior window trim. A fast radial arm saw starter is next, with a ranking to every form of cutting, to provide you an analysis of the capabilities and disadvantages of this instrument.

(Appropriate) Radial Arm Configured

If the saw is fresh, old, or getting pulled out of mothballs, you must take the time (likely a good afternoon) to start things up and change it appropriately.Many manager’s guides contain this detail on “making adjustments.” A 40- or 60-tooth carbide edge of the excellent standard is also another essential.

Get acquainted with the saw’s processes; going from one form of cut to the next typically requires loosening, modifying, and then straightening two levers or cranks. With training, you could move from one activity to the next in much less than a minute.

What is Better Tool for Radial Arm Saws Crosscutting?

With the radial arm saw, cross-cutting will cause beginner carpenters and artisans a bit tense. The blade attempts to drive itself on the panel when you’re not cautious and often jammed on the board. Would there be any way this could be prevented?

The issue with radial arm cutters (and moving alloy miter saws) would be that blade movement appears to push it the same path as cutting. Therefore, all without your support, a blade with such a stuck or favorable rake angle attempts to pull itself by the break. Such experts drag the engine and blade forward after adjust, then place the work surface, and drive the edge via the wood (rather than pull).

But adding a blade that has a tooth with a close to zero angular velocity is another alternative that will allow cutting with your tool much more straightforward and smoother. Less violent inclination significantly decreases the tilt of the blade to move its direction. The saw would not just be good to build, but the saw would also require fewer correction without any impact induced by a damaged saw.

Radial-Arm Saw Features

Massive, rigid equipment which usually is not relatively compact are radial-arm saws. They are often pretty costly and are, therefore, a little hard to keep in place. In specialized wooden stores, so many features make them quite famous, whereby portability is not a problem as well as the holders may learn their usage.

This instrument may be used to tear, break bevels and rabbets, shape paneling, and, in certain situations, also function as a reference for a router, but it is primarily a cross-cut saw. Much of this mobility has trade-offs. At one, it is much more complicated for certain radial-arm saws to build splits than specific other machines.

It is simpler for starters to create a compact miter saw than just a radial arm saw to break compound mitered corners. A table saw to knock-cut products would be a much quicker system. A radial-arm can manage both activities efficiently and, considering its high purchasing cost, provides significant value.

How to use a Radial Arm

For all equipment, remember to learn and completely comprehend the directions which follow your machine until you start on using your radial-arm saw.

Cross-cutting

Fix the edge range just under the machine table while cross-cutting with such an arm-saw. You’ll finish up digging any holes into the sacrificial workspace while utilizing your tool for the first instance, so reduce the blade to the carving spot until the saw’s mechanism is up to standard. No function on a radial-arm saw ever be performed cheap-hand. Still keep the stock it against fencing safely.

The blade’s movement breaks away from the object because you bring the saw towards you via the collection. It might allow the sawdust to float away from the person, but while it slices via the material, it can also trigger the saw edge to swing back or climb further towards you.

Bevels and Miters

Usually, a method detects the saw will break miters to the top or bottom of up to sixty angles and beveled edges of up to 90 °, but generally only in one path. Since this helps a radial-arm saw to slice quite precise composite positions than a compound miter saw, it could also be challenging to correct it. Often see that the fastening mechanisms on the saw are fixed in place until starting a cut.

The saw is the best device for cross-cutting dice and rabbets, especially while creating shelves default threaded inserts or spaces. Lift the blade apart from the table and mount your lined stakes array to the required size, being sure to set it up in the appropriate position for the rotor blade.

Using a visual impairment of stock helps you identify the correct cutting depth for your piece until this set is assembled, and the blade shield is repositioned. Cutting this and rabbets is as simple as turning regular cross-cuts once the installation is finished. The very same package also makes it relatively easy to split tenors.

Rip back

A much less common, and perhaps less efficient, saw feature is to use it for ripping material. Although certain restrictions on cutting sizes can be done on a radial arm, it is no less challenging than using a table saw until the configuration is finished.

Make sure to have still use of the anti-kickback installation consisting of a sawing knife and pawls while constructing the radial-arm saw to tear. The sawing knife is intended to help maintain the stock on the blade from activation. The pawls are built to catch the stock to keep it from forcing back if the blade jammed throughout a rip break.

Suggestions on operations and security

- Dials, buttons, and cranks are galore in a radial arm tool. While using the saw, ensure each one will be set and activated.

- Such clues will also assist:

- Create a tiny hole in the fencing and board for a unique angle cutting by reducing the turning blade through them and slowly raising them.

- Instantly press the off button when the blade gets stuck by a knot or driven into the woods too soon. Learn this step as if a gunslinger was heading for his pistol. Release the edge, then re-start the hack.

- Ensure that the cutting tool adequately installed according to the specifications of the supplier would not only demonstrate to you the functionality of the saw as well as how to do it effectively. Relevant expertise would be needed for each strategy.

- The blade-guard must be considered with caution. Even without blade protection safely in position, the saw must never be switched on, nor the bottom half of the shield be changed entirely to hold it above the tabletop.

- Ensure the shield could be quickly elevated with the saw action, and when issued, it falls back into position.

- Lots of parts can be used to mount your saw. The drum tiller is one fixture that conveniently installs and functions well. Some are tackier, such as molding blades for chopping patterns into a panel’s side or surface. Instead, choose a router.

- It behaves just like a table saw throughout rip chopping and other tasks, with the inventory becoming forced via the saw blade, which has been briefly held in position.

- Setup the whole machine with a gentle backward gradient while constructing the saw. In this method, under its mass, the saw is kept from slipping further into the operator.

- Not initiate a cutting before the saw blade has achieved its full speed.

- Monitor the cutting forces, which would not just make it secure to use but will also yield positive performance for cutting.

- Every time double-check that the physical closeness the product against the barrier, not only when cross-cutting but even when tearing, is apart from the blade’s track. Utilize feather beams as needed and a push tool.

Frequently Asked Questions

Are Radial Arm Saws Still Useful?

Radial arm saws are still useful for a variety of tasks, including cutting lumber, trimming wood, and cutting sheet goods.

There are several factors to consider when choosing a radial arm saw: the size of the blade, the number of cuts it can make in one pass, how easily it can be adjusted, and the type of material you will be cutting.

Some things to keep in mind when using a radial arm saw are to use caution when making long cuts and to wear safety goggles and gloves.

Do You Push or Pull a Radial Arm Saw?

There is no correct answer to this question as it depends on the type of saw that you are using and the task at hand.

If you are using a radial arm saw, then you should push the saw blade forward. This will allow you to make smooth cuts without any jagged edges.

If you are cutting wood with a handsaw, then you should pull the saw blade backward. This will create more of a ripping motion and will result in rougher cuts.

Which Way Do You Feed a Radial Arm Saw?

There are a few ways to feed a radial arm saw. The most common way is to hold the saw with your left hand and use your right hand to guide the blade. You can also hold the saw in your left hand and use your right hand to control the saw’s angle.

Is a Radial Arm Saw Better Than a Table Saw?

There is no one-size-fits-all answer to this question, as the type of saw that is best for you will depend on your specific needs and preferences. However, a radial arm saw is often considered to be a better option than a table saw because it has many advantages over traditional saws.

Some of the key benefits of using a radial arm saw over a table saw include:

• They are easier to use because they have ergonomic designs that make them more comfortable to use.

• They are faster and more efficient because they have more cutting depth and blade speed options than table saws.

• They are less likely to jam because they have fewer moving parts, making them less prone to failure.

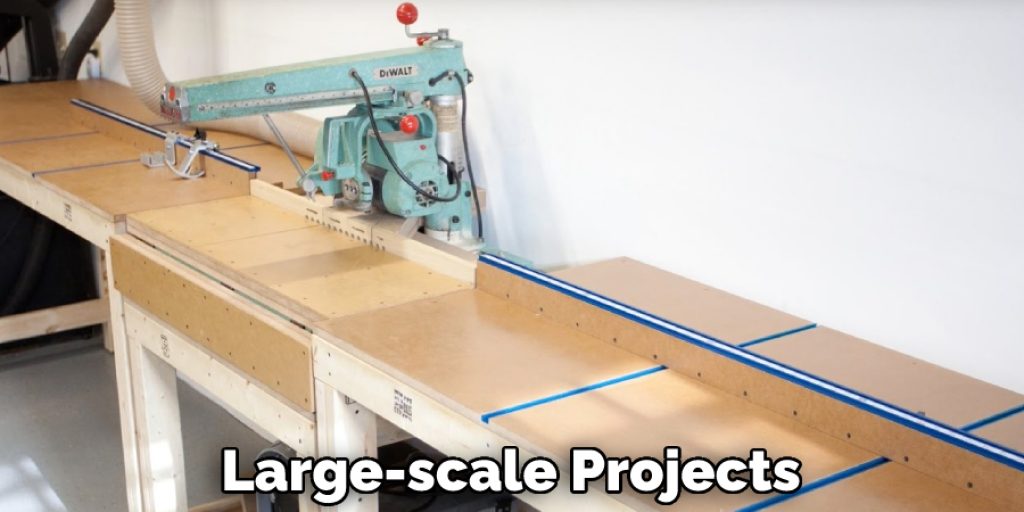

• They are less expensive to operate than table saws, which makes them a better choice if you need to do large-scale projects or repairs.

you may also read now